| Citation: | Zhang CY, Zhou W, Geng D, Bai C, Li WD et al. Laser direct writing and characterizations of flexible piezoresistive sensors with microstructures. Opto-Electron Adv 4, 200061 (2021).. doi: 10.29026/oea.2021.200061 |

Laser direct writing and characterizations of flexible piezoresistive sensors with microstructures

-

Abstract

Functional materials with high viscosity and solid materials have received more and more attentions in flexible pressure sensors, which are inadequate in the most used molding method. Herein, laser direct writing (LDW) method is proposed to fabricate flexible piezoresistive sensors with microstructures on PDMS/ MWCNTs composites with an 8% MWCNTs mass fraction. By controlling laser energy, microstructures with different geometries can be obtained, which significantly impacts the performances of the sensors. Subsequently, curved microcones with excellent performance are fabricated under parameters of f = 40 kHz and v = 150 mm·s-1. The sensor exhibits continuous multi-linear sensitivity, ultrahigh original sensitivity of 21.80 % kPa-1, wide detection range of over 20 kPa, response/recovery time of ~100 ms and good cycle stability for more than 1000 times. Besides, obvious resistance variation can be observed when tiny pressure (a peanut of 30 Pa) is applied. Finally, the flexible piezoresistive sensor can be applied for LED brightness controlling, pulse detection and voice recognition.-

Keywords:

- flexible pressure sensor /

- piezoresistive sensor /

- microstructure /

- laser processing

-

-

References

[1] Chen WF, Yan X. Progress in achieving high-performance piezoresistive and capacitive flexible pressure sensors: a review. J Mater Sci Technol 43, 175–188 (2020). doi: 10.1016/j.jmst.2019.11.010 [2] Chun S, Son W, Choi C. Flexible pressure sensors using highly-oriented and free-standing carbon nanotube sheets. Carbon 139, 586–592 (2018). doi: 10.1016/j.carbon.2018.07.005 [3] Deka BK, Hazarika A, Kim J, Jeong HE, Park YB et al. Fabrication of the piezoresistive sensor using the continuous laser-induced nanostructure growth for structural health monitoring. Carbon 152, 376–387 (2019). doi: 10.1016/j.carbon.2019.06.015 [4] Ma YN, Liu NS, Li LY, Hu XK, Zou ZG et al. A highly flexible and sensitive piezoresistive sensor based on MXene with greatly changed interlayer distances. Nat Commun 8, 1207 (2017). doi: 10.1038/s41467-017-01136-9 [5] Wei Y, Chen S, Dong XC, Lin Y, Liu L. Flexible piezoresistive sensors based on "dynamic bridging effect" of silver nanowires toward graphene. Carbon 113, 395–403 (2017). doi: 10.1016/j.carbon.2016.11.027 [6] Zhang L, Li HQ, Lai XJ, Gao TY, Yang J et al. Thiolated Graphene@Polyester fabric-based multilayer piezoresistive pressure sensors for detecting human motion. ACS Appl Mater Interfaces 10, 41784–41792 (2018). doi: 10.1021/acsami.8b16027 [7] Ma LQ, Yu XC, Yang YY, Hu YG, Zhang XY et al. Highly sensitive flexible capacitive pressure sensor with a broad linear response range and finite element analysis of micro-array electrode. J Materiomics 6, 321–329 (2020). doi: 10.1016/j.jmat.2019.12.008 [8] Yang XF, Wang YS, Qing XL. A flexible capacitive sensor based on the electrospun PVDF nanofiber membrane with carbon nanotubes. Sens Actuators A Phys 299, 111579 (2019). doi: 10.1016/j.sna.2019.111579 [9] Tay RY, Li HL, Lin JJ, Wang H, Lim JSK et al. Lightweight, superelastic boron nitride/polydimethylsiloxane foam as air dielectric substitute for multifunctional capacitive sensor applications. Adv Funct Mater 30, 1909604 (2020). doi: 10.1002/adfm.201909604 [10] Jeong SI, Lee EJ, Hong GR, Jo Y, Jung SM et al. Three-dimensional multistack-printed, self-powered flexible pressure sensor arrays: piezoelectric composites with chemically anchored heterogeneous interfaces. ACS Omega 5, 1956–1965 (2020). doi: 10.1021/acsomega.9b03753 [11] Xu MZ, Kang H, Guan L, Li HY, Zhang MN. Facile fabrication of a flexible LiNbO3 piezoelectric sensor through hot pressing for biomechanical monitoring. ACS Appl Mater Interfaces 9, 34687–34695 (2017). doi: 10.1021/acsami.7b10411 [12] Wang HL, Kuang SY, Li HY, Wang ZL, Zhu G. Large-area integrated triboelectric sensor array for wireless static and dynamic pressure detection and mapping. Small 16, 1906352 (2020). doi: 10.1002/smll.201906352 [13] Fan FR, Lin L, Zhu G, Wu WZ, Zhang R et al. Transparent triboelectric nanogenerators and self-powered pressure sensors based on micropatterned plastic films. Nano Lett 12, 3109–3114 (2012). doi: 10.1021/nl300988z [14] Yuan LQ, Wang ZW, Li HW, Huang YN, Wang SG et al. Synergistic resistance modulation toward ultrahighly sensitive piezoresistive pressure sensors. Adv Mater Technol 5, 1901084 (2020). doi: 10.1002/admt.201901084 [15] Zhang T, Li ZY, Li K, Yang XN. Flexible pressure sensors with wide linearity range and high sensitivity based on selective laser sintering 3D printing. Adv Mater Technol 4, 1900679 (2019). doi: 10.1002/admt.201900679 [16] Pang Y, Zhang KN, Yang Z, Jiang S, Ju ZY et al. Epidermis microstructure inspired graphene pressure sensor with random distributed spinosum for high sensitivity and large linearity. ACS Nano 12, 2346–2354 (2018). doi: 10.1021/acsnano.7b07613 [17] Yang CF, Li LL, Zhao JX, Wang JJ, Xie JX et al. Highly sensitive wearable pressure sensors based on three-scale nested wrinkling microstructures of polypyrrole films. ACS Appl Mater Interfaces 10, 25811–25818 (2018). doi: 10.1021/acsami.8b08666 [18] Liao XQ, Zhang Z, Kang Z, Gao FF, Liao QL et al. Ultrasensitive and stretchable resistive strain sensors designed for wearable electronics. Mater Horiz 4, 502–510 (2017). doi: 10.1039/C7MH00071E [19] Kaps S, Bhowmick S, Gröttrup J, Hrkac V, Stauffer D et al. Piezoresistive response of quasi-one-dimensional ZnO nanowires using an in situ electromechanical device. ACS Omega 2, 2985–2993 (2017). doi: 10.1021/acsomega.7b00041 [20] Cao MH, Wang MQ, Li L, Qiu HW, Padhiar MA et al. Wearable rGO-Ag NW@cotton fiber piezoresistive sensor based on the fast charge transport channel provided by Ag nanowire. Nano Energy 50, 528–535 (2018). doi: 10.1016/j.nanoen.2018.05.038 [21] Park J, Kim J, Hong J, Lee H, Lee Y et al. Tailoring force sensitivity and selectivity by microstructure engineering of multidirectional electronic skins. NPG Asia Mater 10, 163–176 (2018). doi: 10.1038/s41427-018-0031-8 [22] Zhang ZM, Zhang YX, Jiang X, Bukhari H, Zhang ZX et al. Simple and efficient pressure sensor based on PDMS wrapped CNT arrays. Carbon 155, 71–76 (2019). doi: 10.1016/j.carbon.2019.08.018 [23] Bae GY, Pak SW, Kim D, Lee G, Kim DH et al. Linearly and highly pressure-sensitive electronic skin based on a bioinspired hierarchical structural array. Adv Mater 28, 5300–5306 (2016). doi: 10.1002/adma.201600408 [24] Liu L, Huang Y, Li FY, Ma Y, Li WB et al. Spider-web inspired multi-resolution graphene tactile sensor. Chem Commun 54, 4810–4813 (2018). doi: 10.1039/C8CC02339E [25] Tung TT, Robert C, Castro M, Feller JF, Kim TY et al. Enhancing the sensitivity of graphene/polyurethane nanocomposite flexible piezo-resistive pressure sensors with magnetite nano-spacers. Carbon 108, 450–460 (2016). doi: 10.1016/j.carbon.2016.07.018 [26] Yue Y, Liu NS, Liu WJ, Li M, Ma YA et al. 3D hybrid porous Mxene-sponge network and its application in piezoresistive sensor. Nano Energy 50, 79–87 (2018). doi: 10.1016/j.nanoen.2018.05.020 [27] Gao YY, Yan C, Huang HC, Yang T, Tian G et al. Microchannel-confined mxene based flexible piezoresistive multifunctional micro-force sensor. Adv Funct Mater 30, 1909603 (2020). doi: 10.1002/adfm.201909603 [28] Pang Y, Zhang KN, Yang Z, Jiang S, Ju ZY et al. Epidermis microstructure inspired graphene pressure sensor with random distributed spinosum for high sensitivity and large linearity. ACS Nano 12, 2346–2354 (2018). doi: 10.1021/acsnano.7b07613 [29] Nie P, Wang RR, Xu XJ, Cheng Y, Wang X et al. High-performance piezoresistive electronic skin with bionic hierarchical microstructure and microcracks. ACS Appl Mater Interfaces 9, 14911–14919 (2017). doi: 10.1021/acsami.7b01979 [30] Wang J, Tenjimbayashi M, Tokura Y, Park JY, Kawase K et al. Bionic fish-scale surface structures fabricated via air/water interface for flexible and ultrasensitive pressure sensors. ACS Appl Mater Interfaces 10, 30689–30697 (2018). doi: 10.1021/acsami.8b08933 [31] Chang TH, Tian Y, Li CS, Gu XY, Li KR et al. Stretchable graphene pressure sensors with shar-pei-like hierarchical wrinkles for collision-aware surgical robotics. ACS Appl Mater Interfaces 11, 10226–10236 (2019). doi: 10.1021/acsami.9b00166 [32] Xia KL, Wang CY, Jian MQ, Wang Q, Zhang YY. CVD growth of fingerprint-like patterned 3D graphene film for an ultrasensitive pressure sensor. Nano Res 11, 1124–1134 (2018). doi: 10.1007/s12274-017-1731-z [33] Zhou W, Ling WS, Liu W, Peng YJ, Peng JH. Laser direct micromilling of copper-based bioelectrode with surface microstructure array. Opt Laser Eng 73, 7–15 (2015). doi: 10.1016/j.optlaseng.2015.03.011 [34] Gao Y, Li Q, Wu RY, Sha J, Lu YF et al. Laser direct writing of ultrahigh sensitive SiC-based strain sensor arrays on elastomer toward electronic skins. Adv Funct Mater 29, 1806786 (2019). doi: 10.1002/adfm.201806786 [35] Xin YY, Zhou J, Xu XZ, Lubineau G. Laser-engraved carbon nanotube paper for instilling high sensitivity, high stretchability, and high linearity in strain sensors. Nanoscale 9, 10897–10905 (2017). doi: 10.1039/C7NR01626C [36] Huang KY, Ning HM, Hu N, Liu F, Wu XP et al. Ultrasensitive MWCNT/PDMS composite strain sensor fabricated by laser ablation process. Compos Sci Technol 192, 108105 (2020). doi: 10.1016/j.compscitech.2020.108105 [37] Lu C, Gao Y, Yu GH, Xu MD, Tan JP et al. Laser-microengineered flexible electrodes with enhanced sensitivity for wearable pressure sensors. Sens Actuators A Phys 281, 124–129 (2018). doi: 10.1016/j.sna.2018.08.046 [38] Liu W, Xu FJ, Zhu NH, Wang S. Mechanical and electrical properties of carbon nanotube/polydimethylsiloxane composites yarn. J Eng Fiber Fabr 11, 36–42 (2016). [39] Romoli L, Fischer F, Kling R. A study on UV laser drilling of PEEK reinforced with carbon fibers. Opt Laser Eng 50, 449–457 (2012). doi: 10.1016/j.optlaseng.2011.10.008 [40] Zhang DS, Sugioka K. Hierarchical microstructures with high spatial frequency laser induced periodic surface structures possessing different orientations created by femtosecond laser ablation of silicon in liquids. Opto-Electron Adv 2, 190002 (2019). [41] Wang ZY, Guan X, Huang HY, Wang HF, Lin WE et al. Full 3D printing of stretchable piezoresistive sensor with hierarchical porosity and multimodulus architecture. Adv Funct Mater 29, 1807569 (2019). doi: 10.1002/adfm.201807569 [42] Liu WJ, Liu NS, Yue Y, Rao JY, Cheng F et al. Piezoresistive pressure sensor based on synergistical innerconnect polyvinyl alcohol nanowires/wrinkled graphene film. Small 14, 1704149 (2018). doi: 10.1002/smll.201704149 [43] Luo YH, Wu DZ, Zhao Y, Chen QN, Xie Y et al. Direct write of a flexible high-sensitivity pressure sensor with fast response for electronic skins. Org Electron 67, 10–18 (2019). doi: 10.1016/j.orgel.2019.01.001 [44] Nichols WW. Clinical measurement of arterial stiffness obtained from noninvasive pressure waveforms. Am J Hypertens 18, 3–10 (2005). [45] Zhang L, Pan J, Zhang Z, Wu H, Yao N et al. Ultrasensitive skin-like wearable optical sensors based on glass micro/nanofibers. Opto-Electron Adv 3, 190022 (2020). -

Supplementary Information

oea-2020-0061 Supplementary information

-

Access History

Article Metrics

-

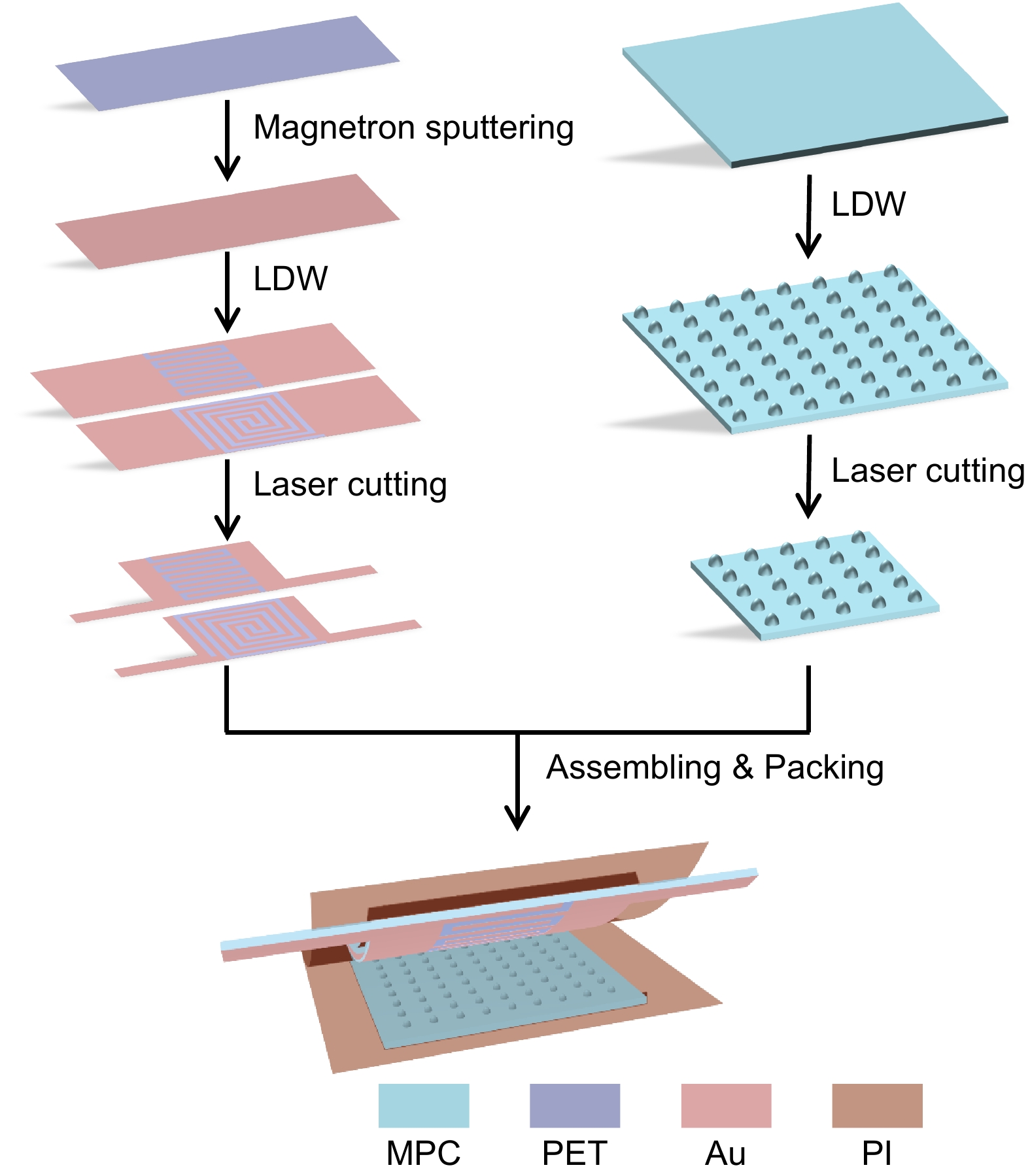

Figure 1.

Design and fabrication of flexible piezoresistive sensor.

-

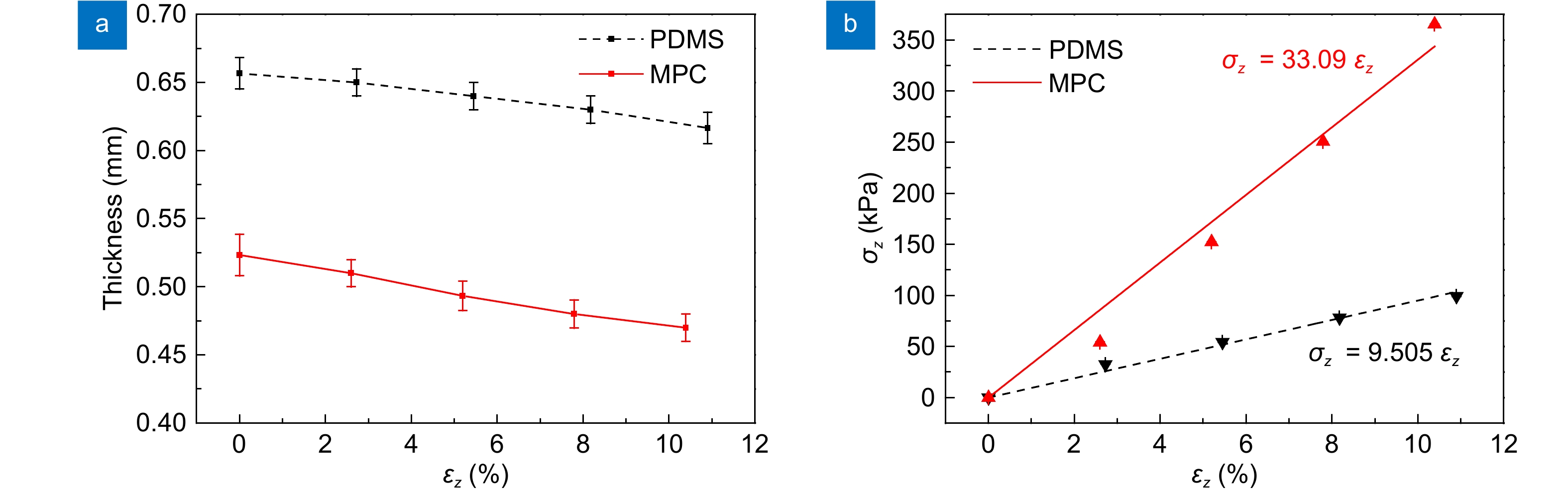

Figure 2.

Mechanical properties of materials. (a) Lateral contraction of MPC and PDMS, (b) σz-εz curves of MPC and PDMS.

-

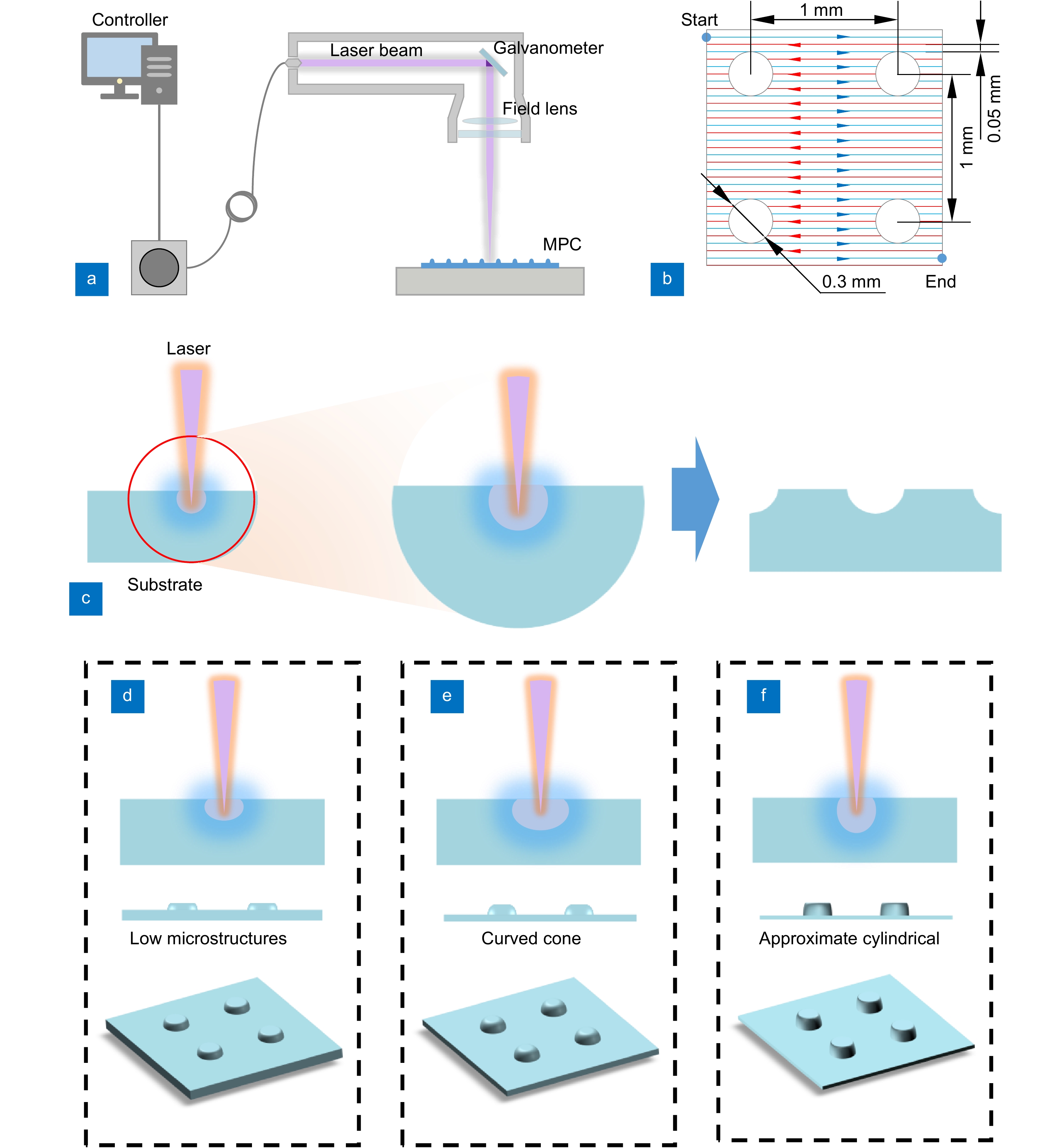

Figure 3.

Fabrication of microstructures. (a) Processing system of LDW. (b) Laser scanning strategy. (c) Schematic of laser processing. (d) Processing schematic of low microstructures. (e) Processing schematic of curved cone-like microstructures. (f) Processing schematic of approximate cylindrical microstructures.

-

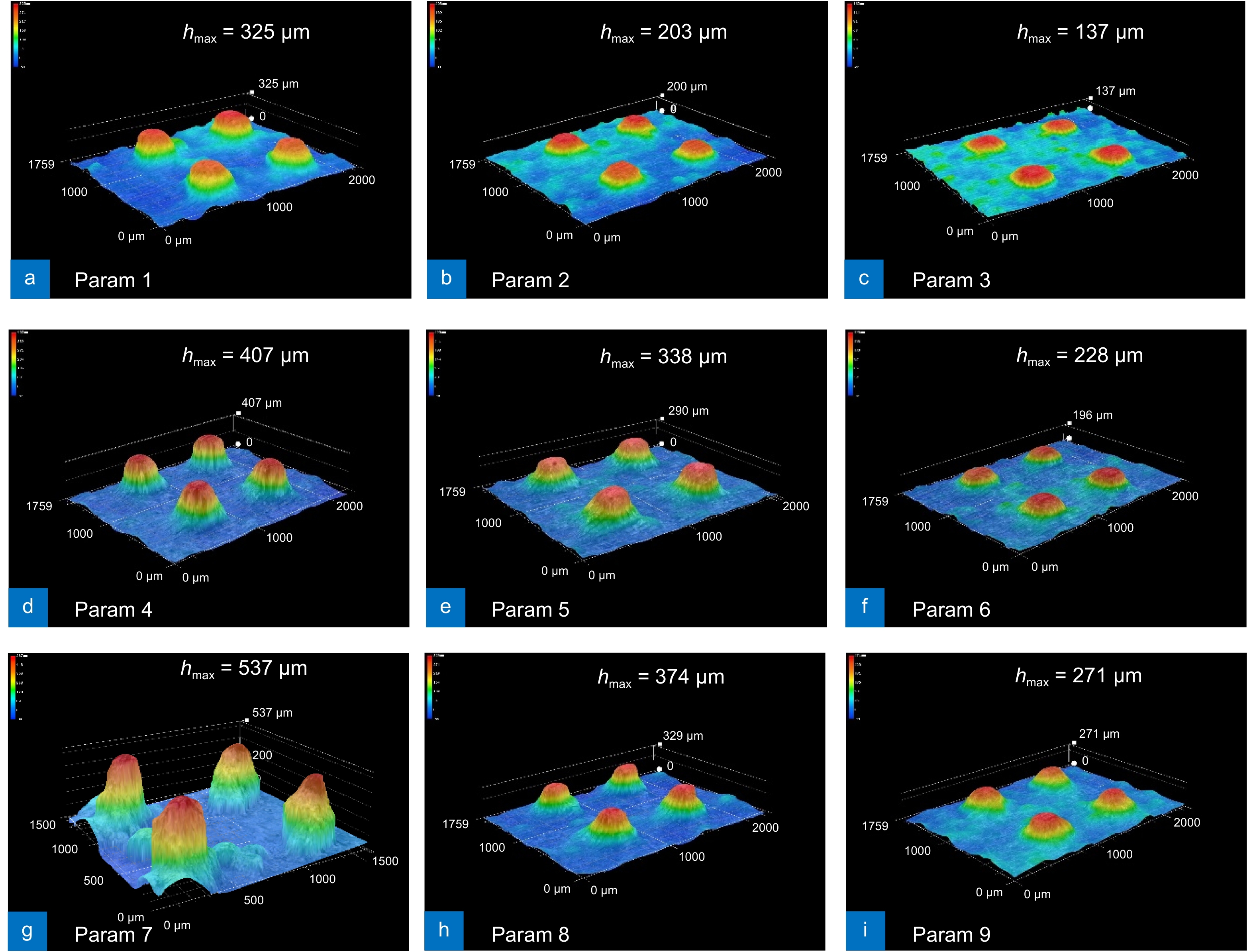

Figure 4.

Surface morphologies of microstructures fabricated with different laser parameters imaged by a super deep scene 3D microscope. (a) Param 1: f = 35 kHz, v = 100 mm·s-1; (b) Param 2: f = 35 kHz, v = 150 mm·s-1; (c) Param 3: f = 35 kHz, v = 200 mm·s-1; (d) Param 4: f = 40 kHz, v = 100 mm·s-1; (e) Param 5: f = 40 kHz, v = 150 mm·s-1; (f) Param 6: f = 40 kHz, v = 200 mm·s-1; (g) Param 7: f = 45 kHz, v = 100 mm·s-1; (h) Param 8: f = 45 kHz, v = 150 mm·s-1; (i) Param 9: f = 45 kHz, v = 200 mm·s-1.

-

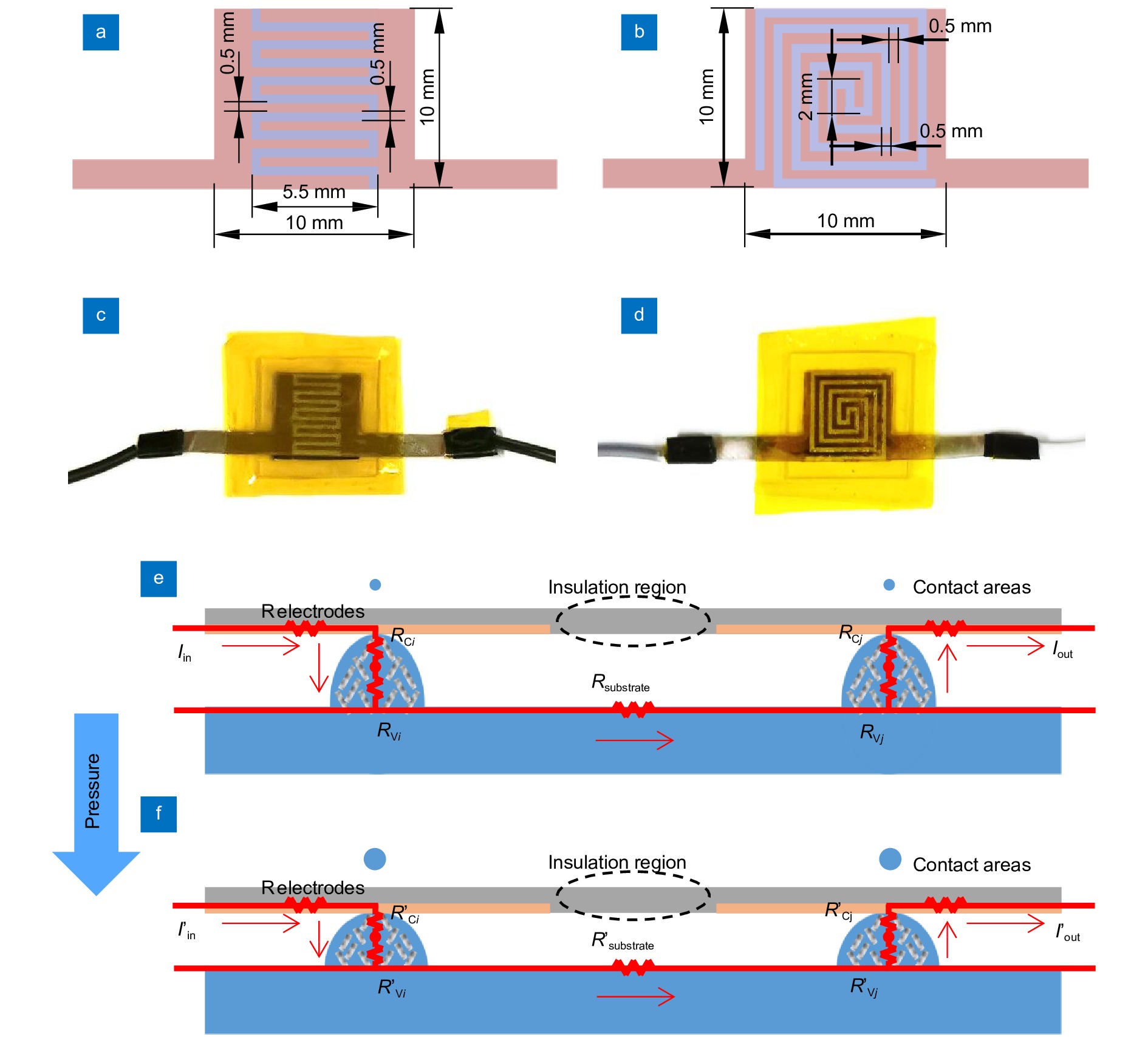

Figure 5.

(a) Design of SLI interdigital electrodes. (b) Design of CRI interdigital electrodes. (c) Image of a sensor with SLI interdigital electrodes. (d) Image of a sensor with CRI interdigital electrodes. (e, f) Equivalent model of resistance in flexible piezoresistive sensors (e) without pressure, (f) under pressure.

-

Figure 6.

(a) Sensitivity properties of flexible piezoresistive sensors fabricated with different laser processing parameters. (b) Resistance variations with pressure of sensors packed with different interdigital electrodes within 8 kPa pressure. (c) Resistance variations with pressure of sensors fabricated with Param 5 and the planar one without microstructures. (d) I-V curves of sensor fabricated with Param 5 under different pressure.

-

Figure 7.

(a) Resistance variation toward step load. (b) Resistance variation toward pressure of a peanut. (c) Cycle stability within 1000 cycle times at 7 kPa pressure.

-

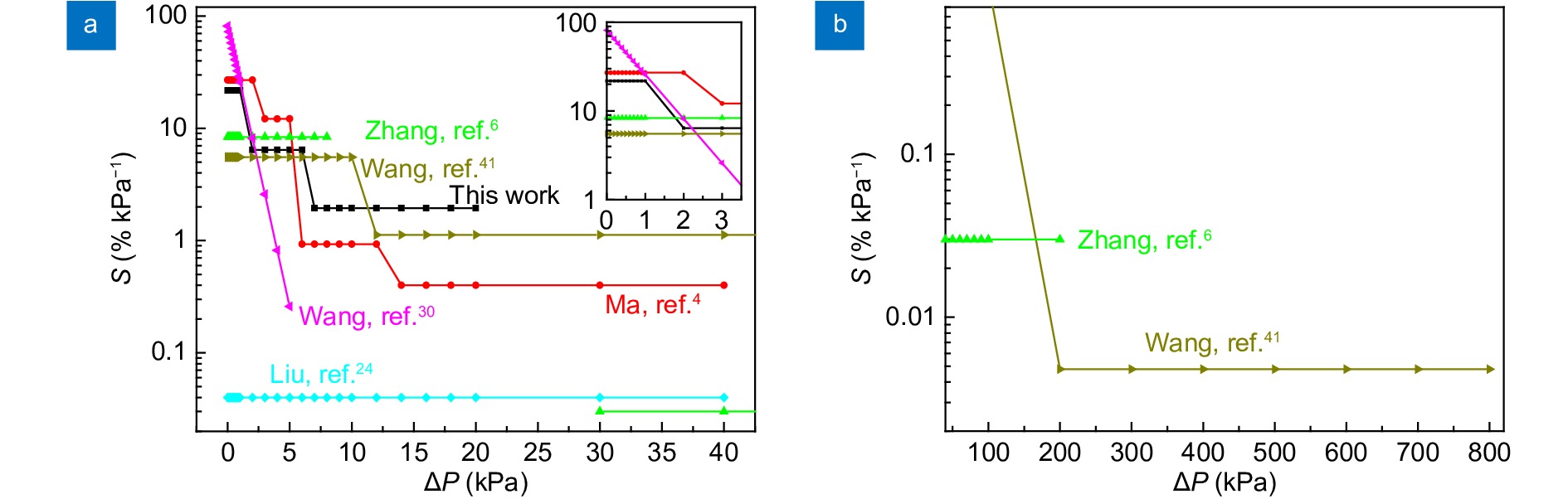

Figure 8.

Sensitivity variations with pressure of this work and typical references4,6,24,30,41. (a) Within 40 kPa pressure. (b) Over 40 kPa pressure.

-

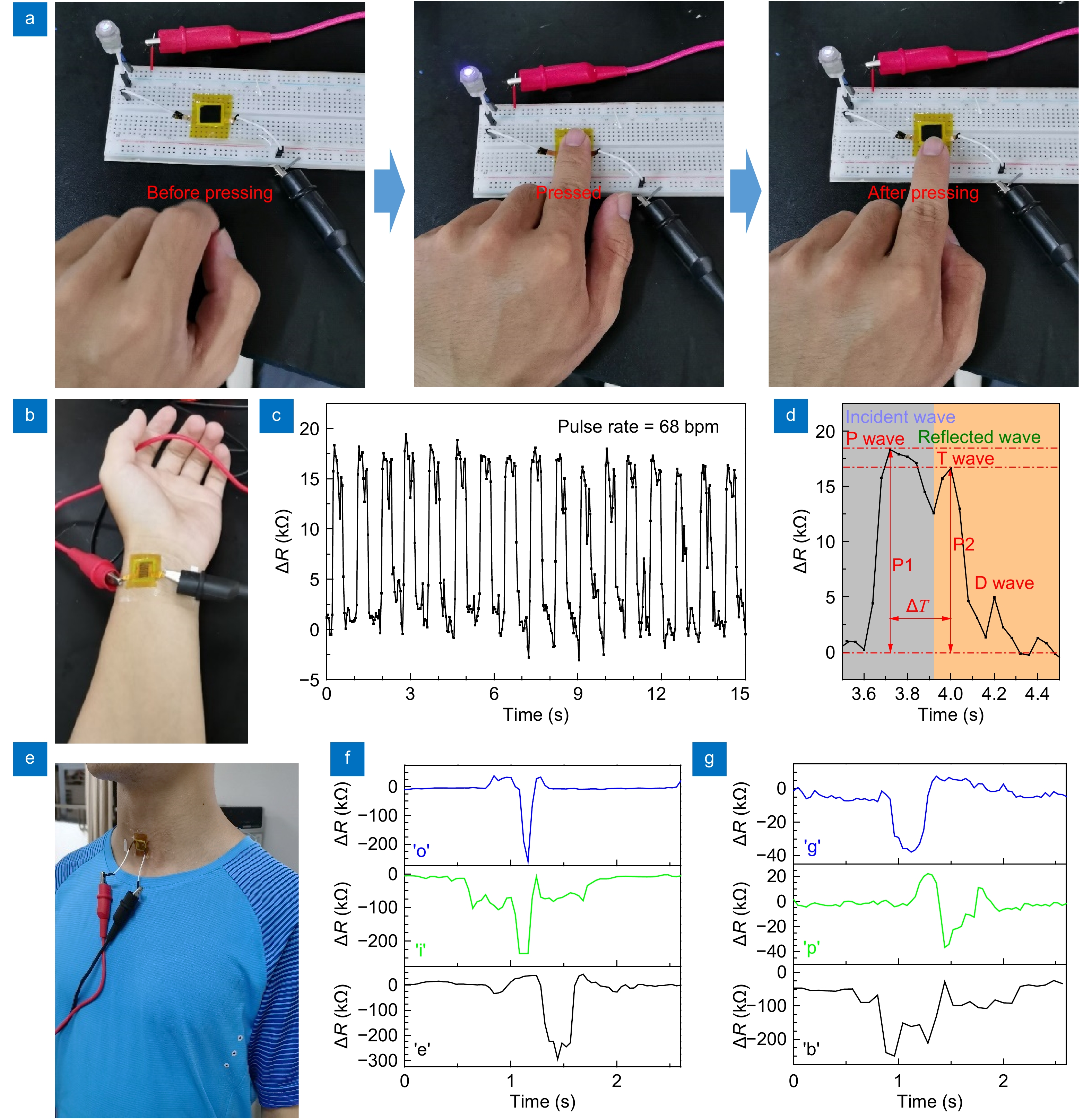

Figure 9.

Applications of the flexible piezoresistive sensor. (a) LED brightness controlling. (b) Pulse detection. (c) Pulse wave detected from wrist. (d) Magnified wave from panel (c). (e) Voice recognition from vocal cords. (f) Waves of different vowels. (g) Waves of different consonants.

E-mail Alert

E-mail Alert RSS

RSS

DownLoad:

DownLoad: