Effect of deposition efficiency on microstructure and property of 316L stainless steel fabricated by laser engineered net shaping

-

摘要:

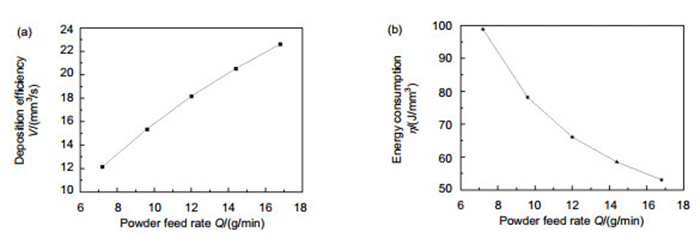

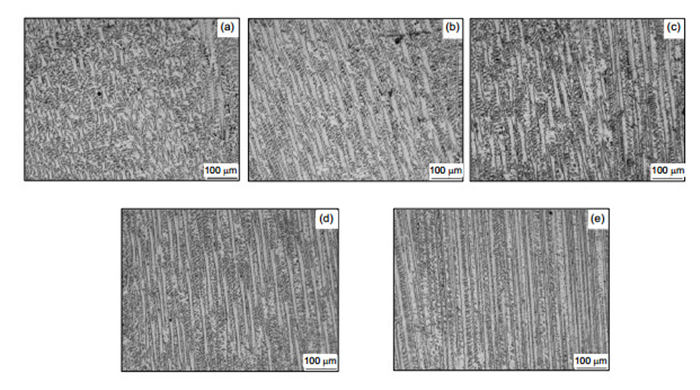

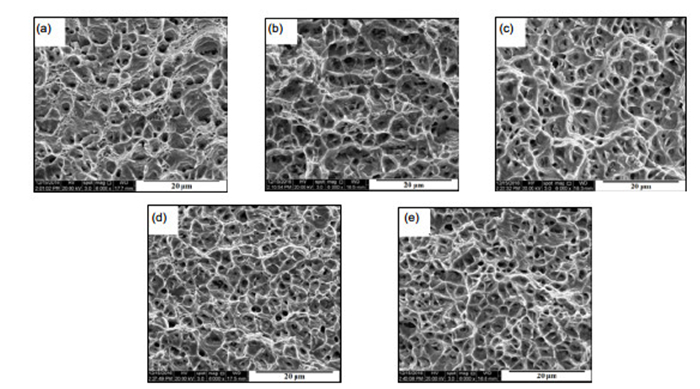

利用激光近净成形技术进行了316L不锈钢单道多层结构的制备。在相同的激光功率及扫描速度条件下,通过调整送粉率及层间提升量实现了不同沉积效率的成形,并讨论了不同沉积效率下成形结构的微观组织及力学性能特征。结果表明,在一定的激光功率及扫描速度条件下,随着送粉率及层间提升量的提升,沉积效率由初始工艺参数条件下的12.14 mm3/s提高至22.62 mm3/s,提高了86.3%。同时成形单位有效体积消耗的激光能量由初始工艺参数条件下的98.84 J/ mm3降低至53.06 J/mm3,能量利用效率提高了46.32%。成形结构的微观组织呈柱状枝晶形态,随着沉积效率的提高,枝晶长度呈明显的增大趋势。性能检测结果显示,不同沉积效率下的样件力学性能保持了较高的一致性,并未随沉积效率的提高而降低,成形样件抗拉强度及屈服强度分别稳定在510 MPa与290 MPa,延伸率稳定在40%左右,显微硬度也未出现明显波动,处于180 HV,均达到了锻造的同等水平。该研究表明,在一定的工艺参数范围内,可以实现沉积效率及力学性能的协同优化,达到低能耗高效制备高性能零件的效果。

Abstract:

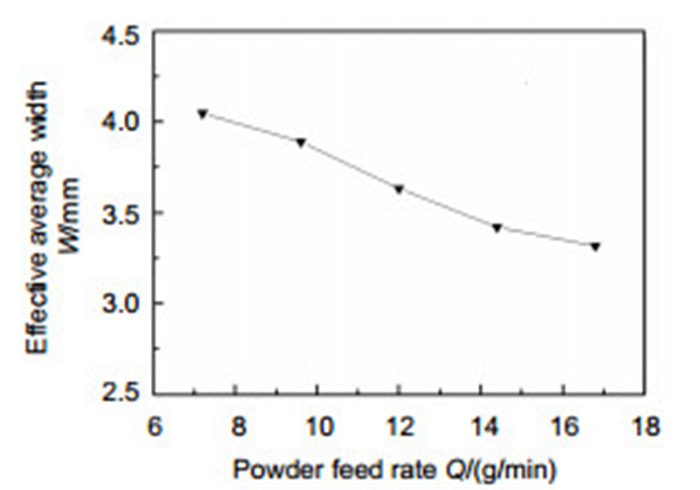

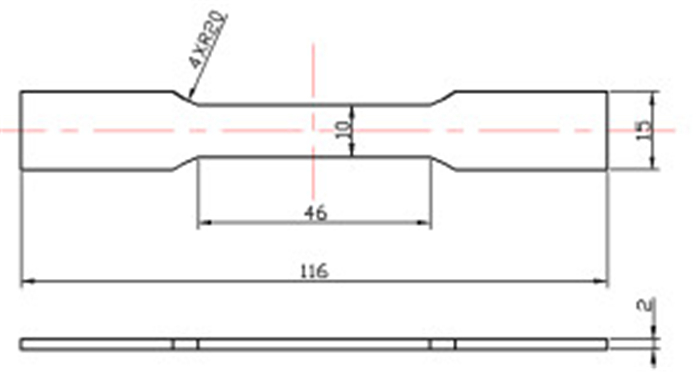

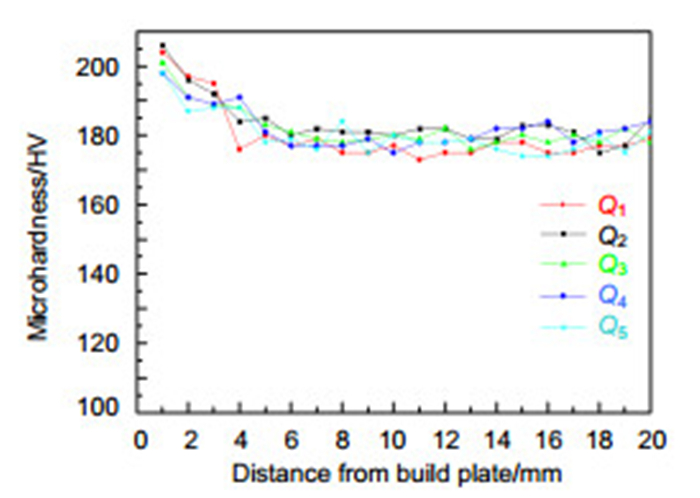

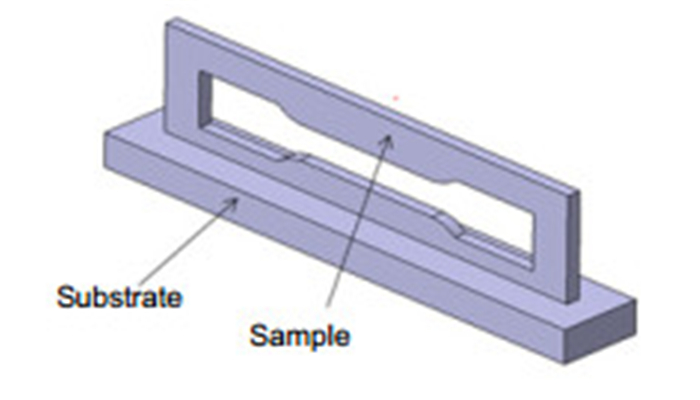

Abstract:Laser engineered net shaping is a promising technique to fabricate high-performance components with complex geometry rapidly. Excellent properties of fabricated specimen and high deposition efficiency are both important for this additive manufacturing method, but few researches have been done on the relationship between them. In this paper, single-bead multilayer structures of 316L stainless steel are fabricated by laser engineered net shaping (LENS). Using the same laser power and scanning speed, different deposition efficiencies are achieved by adjusting powder flow rate and layer increment. Microstructures and mechanical properties of the deposited structures under different deposition efficiencies are discussed. The results show that, for certain laser power and scanning speed, the deposition efficiency increases from 12.41 mm3/s to 22.62 mm3/s with the increase of the powder flow rate and layer increment, which increases by 86.3% compared with the initial process. Laser energy consumed by depositing unit effective volume reduces from initial 98.84 J/mm3 to 53.06 J/mm3 and the energy efficiency increases by 46.32%. Microstructures of the specimen consist of columnar dendrite and the dendrite length increases obviously with the deposition efficiency. Property test shows that properties of the specimen under different deposition efficiencies are consistent and do not decrease with the deposition efficiency. Tensile strength and yield strength are stable in 510 MPa and 290 MPa, respectively. The elongation rate is around 40% while the micro-hardness is about 180 HV, all of which have reached the same level of forging. The results illustrate that the deposition efficiency and mechanical property can be optimized, which achieves fabrication of high performance parts with low energy consumption and high efficiency.

-

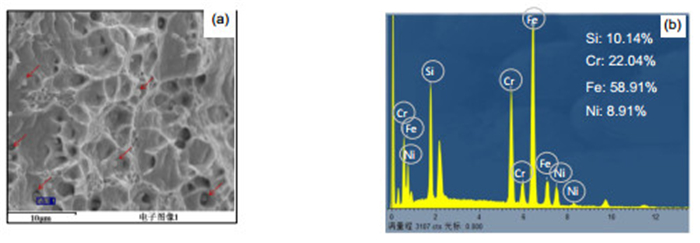

Abstract:Laser engineered net shaping is a promising additive manufacturing technique that can be used for building three-dimensional components directly from CAD models by layer-wise deposition. Components with high performance and complex geometry can be achieved rapidly by this technology, and components of metal, ceramic or composite material have been successfully fabricated and used in many industrial field. High properties of fabricated specimens and high deposition efficiency are both important for laser engineered net shaping, but few researches have been done on the relationship between them. In this paper, single-bead multilayer structures of 316L stainless steel are fabricated by laser engineered net shaping system. Using the same laser power and scanning speed, different deposition efficiencies are achieved by adjusting powder flow rate and layer increment. Microstructure of each specimen is analyzed by SEM. Tensile strength and micro-hardness of the deposited structures under different deposition efficiencies are tested, respectively. Effect of deposition efficiency on microstructure and properties of fabricated 316L stainless steel are discussed. The results show that, for certain laser power and scanning speed, the deposition efficiency increases from 12.41 mm3/s to 22.62 mm3/s with the increase of the powder flow rate and layer increment, which increases by 86.3% compared with the initial process. Laser energy consumed by depositing unit effective volume reduces from initial 98.84 J/mm3 to 53.06 J/mm3 and the energy efficiency increases by 46.32%. Microstructure of the specimen consists of columnar dendrite and the dendrite length increases obviously with the deposition efficiency. Property test results show that properties of the specimens under different deposition efficiencies are consistent and do not decrease with the deposition efficiency. Tensile strength and yield strength are stable in 510 MPa and 290 MPa, respectively, and the elongation rate is around 40%. The precipitation of inclusions between grain boundaries is the main reason for the generation of tensile initial defects. Micro-hardness near the substrate of all specimens is higher than other position due to finer microstructure resulted from faster conduction heat dissipation through substrate. As a whole, the micro-hardness is stable at 173~184 MPa. Both the tensile property and micro-hardness of fabricated specimens have reached the same levels of forging. The research in this paper illustrates that the deposition efficiency of laser engineered net shaping and mechanical properties of fabricated structures can be optimized together during certain process window, which achieves fabrication of high performance parts with low energy consumption and high efficiency.

-

-

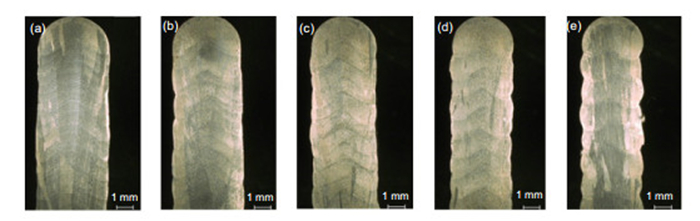

图 4 316L不锈钢薄壁件纵截面局部低倍放大图.(a) Q=7.2 g/min. (b) Q=9.6 g/min. (c) Q=12 g/min. (d) Q=14.4 g/min. (e) Q=16.8 g/min.

Figure 4. Local low magnification of the longitudinal section of the 316L stainless steel thin-walled parts. (a) Q=7.2 g/min. (b) Q=9.6 g/min. (c) Q=12 g/min. (d) Q=14.4 g/min. (e) Q=16.8 g/min.

表 1 316L不锈钢粉末化学成分(质量分数,%).

Table 1. Chemical composition of 316L stainless steel powder(wt, %).

Element C Cr Ni Mo Si Cu Al Fe Wt(%) < 0.03 17.45 11.91 2.82 1.1 7 0.11 0.03 bal. 表 2 激光近净成形工艺参数.

Table 2. Process parameters of laser engineered net shaping.

Serial number 1 2 3 4 5 Powder feed rate/(g/min) 7.2 9.6 12 14.4 16.8 Interlayer lifting capacity/mm 0.6 0.8 1.0 1.2 1.4 表 3 不同送粉量对应的沉积效率、消耗能量.

Table 3. Deposition efficiency and energy consumption corresponding to different powder feeding rates.

Powder feed rate/(g/min) 7.2 9.6 12 14.4 16.8 Energy input time/s 1400 1064 840 700 616 Deposition efficiency V(mm3/s) 12.14 15.36 18.17 20.52 22.62 Energy consumption η/(J/mm3) 98.84 78.15 66.06 58.48 53.06 表 4 激光近净成形316L不锈钢平均抗拉强度、屈服强度、延展性以及同铸造、锻造性能的对比.

Table 4. Average tensile strength, yield strength and ductility of laser engineered net shaping as well as compared with casting and forging properties.

Powder feed rate/(g/min) Tensile strength/MPa Yield strength/MPa Elongation rate/(%) 7.2 509 284 30.4 9.6 508 292 39.9 12.0 505 292 40.2 14.4 506 294 39.7 16.8 507 289 39.1 Casting 440 180 30 Forging 480 177 40 -

[1] 吴东江, 卢卫锋, 陈云啸, 等. ZrO2-13%Al2O3陶瓷薄壁件激光近净成形实验[J].中国激光, 2012, 39(7): 703004. http://www.opticsjournal.net/abstract.htm?id=OJ120524000105QnTpWs

Wu Dongjiang, Lu Weifeng, Chen Yunxiao, et al. Experimental study on ceramic of ZrO2-13%Al2O3 by laser engineered net shaping[J]. Chinese Journal of Lasers, 2012, 39(7): 703004. http://www.opticsjournal.net/abstract.htm?id=OJ120524000105QnTpWs

[2] 吴东江, 孙贝, 牛方勇, 等.激光近净成形不同颜色Al2O3陶瓷件微观组织及裂纹分析[J].硅酸盐学报, 2013, 41(12): 1621-1626. https://www.researchgate.net/profile/Dongjiang_Wu/publication/262900221_Microstructure_and_Crack_in_Color_Al2O3_Samples_by_Laser_Engineered_Net_Shaping/links/54e27fbf0cf2966637969e43.pdf?inViewer=true&pdfJsDownload=true&disableCoverPage=true&origin=publication_detail

Wu Dongjiang, Sun Bei, Niu Fangyong, et al. Microstructure and crack in color Al2O3 samples by laser engineered net shaping[J]. Journal of the Chinese Ceramic Society, 2013, 41(12): 1621-1626. https://www.researchgate.net/profile/Dongjiang_Wu/publication/262900221_Microstructure_and_Crack_in_Color_Al2O3_Samples_by_Laser_Engineered_Net_Shaping/links/54e27fbf0cf2966637969e43.pdf?inViewer=true&pdfJsDownload=true&disableCoverPage=true&origin=publication_detail

[3] 席明哲, 张永忠, 章萍芝, 等.扫描速度对激光快速成型316L不锈钢组织性能的影响[J].稀有金属, 2002, 26(2): 93-97. http://www.cnki.com.cn/Article/CJFDTotal-JJZZ201504027.htm

Xi Mingzhe, Zhang Yongzhong, Zhang Pingzhi, et al. Influence of scanning velocity on microstructure and mechanical properties of 316l stainless steel fabricated by laser rapid prototyping[J]. Chinese Journal of Rare Metals, 2002, 26(2): 93-97. http://www.cnki.com.cn/Article/CJFDTotal-JJZZ201504027.htm

[4] 张永忠, 席明哲, 石力开, 等.激光快速成形316L不锈钢的组织及性能[J].稀有金属材料与工程, 2002, 31(2): 103-105. http://www.opticsjournal.net/abstract.htm?aid=OJ1504020000288EaGdJ

Zhang Yongzhong, Xi Mingzhe, Shi Likai, et al. Microstructure and properties of 316L stainless steel fabricated by laser direct forming[J]. Rare Metal Materials and Engineering, 2002, 31(2): 103-105. http://www.opticsjournal.net/abstract.htm?aid=OJ1504020000288EaGdJ

[5] 杨健, 黄卫东, 杨海欧.激光快速成形316L不锈钢残余应力分布[J].应用激光, 2005, 25(3): 151-154. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yyjg200503003

Yang Jian, Huang Weidong, Yang Hai'ou. Study on the planar residual stress distribution of laser rapid forming 316L shect[J]. Applied Laser, 2005, 25(3): 151-154. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yyjg200503003

[6] 于君, 陈静, 谭华, 等.激光快速成形工艺参数对沉积层的影响[J].中国激光, 2007, 34(7): 1014-1018. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgjg200707024

Yu Jun, Chen Jing, Tan Hua, et al. Effect of process parameters in the laser rapid forming on deposition layer[J]. Chinese Journal of Lasers, 2007, 34(7): 1014-1018. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgjg200707024

[7] De Lima M S F, Sankaré S. Microstructure and mechanical behavior of laser additive manufactured AISI 316 stainless steel stringers[J]. Materials & Design, 2014, 55: 526-532. http://cn.bing.com/academic/profile?id=d057351ea3a43a52781d0d88c9111d94&encoded=0&v=paper_preview&mkt=zh-cn

[8] Zietala M, Tomasz T, Polański M, et al. The microstructure, mechanical properties and corrosion resistance of 316L stainless steel fabricated using laser engineered net shaping[J]. Materials Science and Engineering A, 2016, 677: 1-10. doi: 10.1016/j.msea.2016.09.028 https://www.researchgate.net/publication/308136533_The_microstructure_mechanical_properties_and_corrosion_resistance_of_316L_stainless_steel_fabricated_using_laser_engineered_net_shaping

[9] Zhang Kai, Wang Shijie, Liu Weijun, et al. Characterization of stainless steel parts by laser metal deposition shaping[J]. Materials & Design, 2014, 55: 104-119. http://cn.bing.com/academic/profile?id=ed59865b50f9795fcea1fe055ed44b28&encoded=0&v=paper_preview&mkt=zh-cn

[10] Zhang Kai, Liu Weijun, Shang Xiaofeng. Research on the processing experiments of laser metal deposition shaping[J]. Optics & Laser Technology, 2007, 39(3): 549-557. http://cn.bing.com/academic/profile?id=475aaeb0a1b7fca5f659d7a29ba88e91&encoded=0&v=paper_preview&mkt=zh-cn

[11] Niu Fangyong, Wu Dongjiang, Zhou Siyu, et al. Power prediction for laser engineered net shaping of Al2O3 ceramic parts[J]. Journal of the European Ceramic Society, 2014, 34(15): 3811-3817. doi: 10.1016/j.jeurceramsoc.2014.06.023 https://www.researchgate.net/publication/264560397_Power_prediction_for_laser_engineered_net_shaping_of_Al2O3_ceramic_parts

[12] Gäumann M, Henry S, Cléton F, et al. Epitaxial laser metal forming: analysis of microstructure formation[J]. Materials Science and Engineering A, 1999, 271(1-2): 232-241. doi: 10.1016/S0921-5093(99)00202-6 https://www.researchgate.net/publication/222240475_Epitaxial_laser_metal_forming_Analysis_of_microstructure_formation

[13] Rappaz M, David S A, Vitek J M, et al. Development of microstructures in Fe-15Ni-15Cr single crystal electron beam welds[J]. Metallurgical Transactions A, 1989, 20(6): 1125-1138. doi: 10.1007/BF02650147

[14] 宋建丽, 邓琦林, 胡德金, 等.激光熔覆成形316L不锈钢组织的特征与性能[J].中国激光, 2005, 32(10): 1441-1444. doi: 10.3321/j.issn:0258-7025.2005.10.031 http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jjzz200510030&dbname=CJFD&dbcode=CJFQ

Song Jianli, Deng Qilin, Hu Dejin, et al. Microstructure characterization and properties of laser cladding forming 316L stainless steel[J]. Chinese Journal of Lasers, 2005, 32(10): 1441-1444. doi: 10.3321/j.issn:0258-7025.2005.10.031 http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jjzz200510030&dbname=CJFD&dbcode=CJFQ

[15] 席明哲, 张永忠, 章萍芝, 等.工艺参数对激光快速成型316L不锈钢组织性能的影响[J].中国激光, 2002, 29(11): 1045-1048. doi: 10.3321/j.issn:0258-7025.2002.11.021

Xi Mingzhe, Zhang Yongzhong, Zhang Pingzhi, et al. Influence of processing parameter on the microstructure and properties of the 316L SS fabricated by laser direct deposition[J]. Chinese Journal of Lasers, 2002, 29(11): 1045-1048. doi: 10.3321/j.issn:0258-7025.2002.11.021

[16] Kurz W, Fisher D J. Fundamentals of solidification[M]. Uetikon-Zuerich, Switzerland: Trans Tech Publications Ltd, 1998.

[17] 冯莉萍, 黄卫东, 李延民, 等.基材晶体取向对激光多层涂覆微观组织的影响[J].中国激光, 2001, 28(10): 949-952. doi: 10.3321/j.issn:0258-7025.2001.10.022

Feng Liping, Huang Weidong, Li Yanmin, et al. Influences of crystal orientation of substrate on microstructure of multi-layer laser cladding[J]. Chinese Journal of Lasers, 2010, 28(10): 949-952. doi: 10.3321/j.issn:0258-7025.2001.10.022

[18] Casati R, Lemke J, Vedani M. Microstructure and fracture behavior of 316L austenitic stainless steel produced by selective laser melting[J]. Journal of Materials Science & Technology, 2016, 32(8): 738-744. http://cn.bing.com/academic/profile?id=a969b1f33c20cf8fe98e76cdbb891156&encoded=0&v=paper_preview&mkt=zh-cn

[19] Yadollahi A, Shamsaei N, Thompson S M, et al. Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel[J]. Materials Science and Engineering A, 2015, 644: 171-183. doi: 10.1016/j.msea.2015.07.056 https://www.researchgate.net/publication/281686452_Effects_of_Process_Time_Interval_on_the_Mechanical_and_Microstructural_Properties_of_Direct_Laser_Deposited_316L_Stainless_Steel

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: