-

摘要:

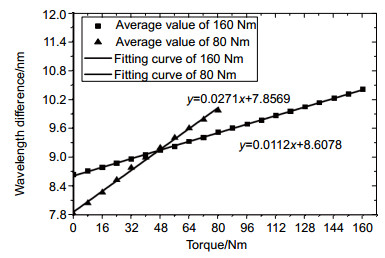

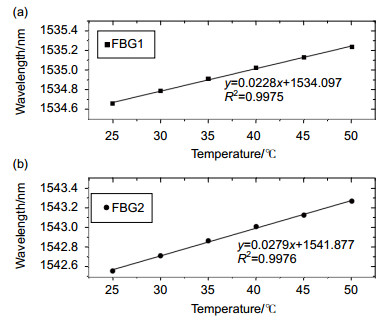

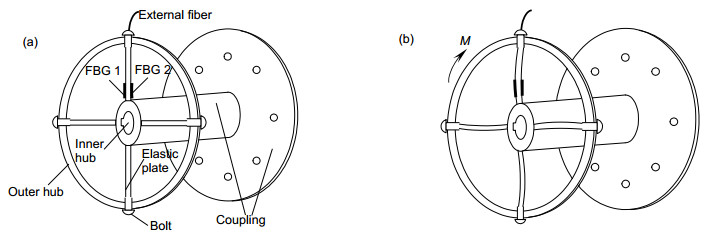

设计了一种以轮辐结构作为弹性元件的可调量程的光纤布拉格光栅扭矩传感器。在弹性板与轴向平行的上下表面对称粘贴两个中心波长不同的光纤布拉格光栅,分别作为传感元件和参考元件。通过对扭矩值与两者反射中心波长差值的标定,可以排除环境温度的影响,实现温度自补偿的功能。采用卡口连接的方式将弹性板与内轮毂、外轮毂进行连接,并用螺栓固定,通过更换弹性板可以调整传感器的量程。经仿真分析和扭矩传感实验证明,量程为80 Nm时,扭矩传感器的平均应变灵敏度为27.1 pm/Nm,相关系数为0.997,重复性误差为3.23% FS,迟滞误差为1.03% FS。

Abstract:

Abstract:Using the spoke structure as the elastic element, an adjustable range fiber grating torque sensor is designed. Two fiber Bragg gratings with different central wavelengths are symmetrically bonded on the upper and lower surfaces of the elastic plate parallel to the axial direction, respectively, as sensing elements and reference elements. By calibrating the relationship between the torque values and the central wavelength difference between the two reflecting elements, the influence of ambient temperature can be eliminated, and the self compensation function of temperature can be realized. The elastic plate is connected with the inner wheel hub and the outer wheel hub by a bayonet, and is fixed by bolts, and the structure is easy to be disassembled so the range of the sensor can be adjusted by replacing the elastic plate. The dimension of spoke structure is optimized by using the finite element simulation software. The finite element simulation and experimental results show that the strain of the elastic element has a linear relationship with the central wavelength difference of two fiber gratings. When the range is 80 Nm, the average sensitivity of the sensor is 27.1 pm/Nm, the correlation coefficient is 0.997, the repeat ability error is 3.23% FS, and the hysteresis error is 1.03% FS.

-

Key words:

- spoke structure /

- fiber Bragg grating /

- torque /

- adjustable range

-

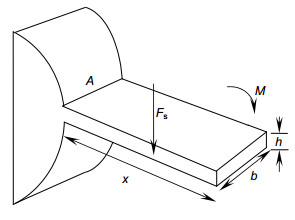

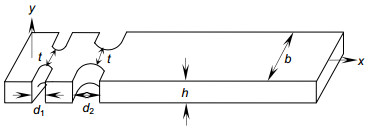

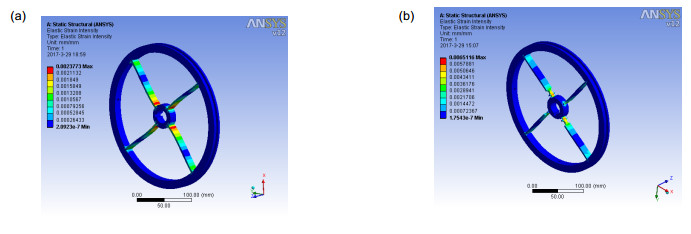

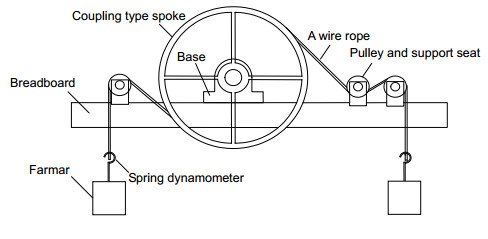

The torque parameters of the mechanical equipment can reflect the performance of the rotating power mechanical system and provide scientific data for the parts to be measured. Compared with the electric and magnetic torque sensors, FBG sensors have many advantages such as high temperature resistance, radiation resistance, safety and reliability. Using the spoke structure as the elastic element, an adjustable range FBG torque sensor is designed. The FBG torque sensor mainly consists of an inner wheel hub, an outer wheel hub, four elastic plates, a coupling and FBG. Two FBGs with different central wavelengths are symmetrically bonded on the upper and lower surfaces of the elastic plate parallel to the axial direction, respectively, as sensing elements and reference elements. In the packaging process, by applying slight adjustable pre-stressing on both sides of the FBG, it can effectively prevent the contraction of FBG in the curing process, as well as the chirp of FBG reflection spectrum and nonlinear distortion of center wavelength. When the torsion force is applied to the hub, two FBGs are subjected to tension and pressure respectively, leading to the center wavelength of the grating moving to opposite directions. By calibrating the relationship between the torque values and the central wavelength difference between the two reflecting elements, the influence of ambient temperature can be eliminated, and the self compensation function of temperature can be realized. The angle between adjacent elastic plates is 90o, the elastic plate is connected with the inner wheel hub and the outer wheel hub by a bayonet, and is fixed by bolts. At the same time, a new type of elastic plate with double grooves is designed on the basis of strip elastic plate, and the range of the sensor is adjusted by replacing the elastic plate without changing the overall structure of the torque sensor. The inner wheel hub is connected with the coupling, thereby improving the practicability and the versatility of the sensor. The torque sensing model of fiber grating is established and the dimension of spoke structure is optimized by using the finite element simulation software. The finite element simulation and experimental results show that the strain of the elastic element has a linear relationship with the central wavelength difference of two fiber gratings. When the range is 80 Nm, the average sensitivity of the sensor is 27.1 pm/Nm, the correlation coefficient is 0.997, the repeat ability error is 3.23% FS, and the hysteresis error is 1.03% FS.

-

-

表 1 不同轮辐尺寸有限元分析结果.

Table 1. The finite element analysis results of different spoke size.

Number Inside hub outer

diameter/mmOuter hub inner

diameter/mmRadial thickness

/mmAxial

width/mmStress intensity

/MPaMaximum

strain/με1 50 170 4 13 297 1934 2 50 170 4 15 266 1734 3 50 170 6 13 147 960 4 50 170 6 15 128 832 表 2 轮辐结构有限元分析结果.

Table 2. Finite element analysis results of spoke structure.

Parameter Double grooved spoke Original spoke Inside hub outer diameter/mm 45 45 Outer hub inner diameter/mm 235 235 Radial thickness/mm 4 4 Axial width/mm 15 15 Minimum axial width/mm 7.5 15 Stress intensity/MPa 1001 365 Maximum strain/ps 6511 2377 表 3 相同行程中各扭矩梯度的标准偏差.

Table 3. Standard deviation of each torque gradient in the same stroke.

Torque/Nm Standard deviation of

positive stroke/nmStandard deviation of reverse

stroke/nm0 0.0005 0.0005 8 0.0235 0.0058 16 0.0126 0.0047 24 0.0120 0.0026 32 0.0120 0.0037 40 0.0120 0.0042 48 0.0162 0.0042 56 0.0141 0.0110 64 0.0094 0.0099 72 0.0251 0.0115 80 0.0251 0.0251 表 4 正、反行程平均校准点及偏差值.

Table 4. The average calibration points and deviation values.

Torque/Nm Positive stroke average

calibration point/nmReverse stroke average

calibration point/nmPositive and reverse

deviation/nm0 7.821 7.819 0.002 8 8.031 8.053 0.022 16 8.261 8.267 0.006 24 8.520 8.526 0.006 32 8.779 8.777 0.002 40 8.990 8.988 0.002 48 9.187 9.193 0.006 56 9.397 9.406 0.009 64 9.607 9.591 0.016 72 9.788 9.791 0.003 80 9.966 9.966 0 -

[1] 宋春华, 徐光卫.扭矩传感器的发展研究综述[J].微特电机, 2012, 40(11): 58–60. doi: 10.3969/j.issn.1004-7018.2012.11.018

Song Chunhua, Xu Guangwei. Development and research overview on torque sensor[J]. Small & Special Electrical Ma-chines, 2012, 40(11): 58–60. doi: 10.3969/j.issn.1004-7018.2012.11.018

[2] 胡德福.应变式扭矩传感器的设计技术[J].船舶工程, 2001, 33(4): 96–99. https://www.wenkuxiazai.com/doc/0d2c503d376baf1ffc4fade3-2.html

Hu Defu. Design of the strain torque sensor[J]. Ship Engineering, 2001, 33(4): 96–99. https://www.wenkuxiazai.com/doc/0d2c503d376baf1ffc4fade3-2.html

[3] 张彩妮, 王向朝.微角度的光学测量[J].光电子?激光, 2002, 13(4): 416–419. http://www.cqvip.com/qk/92586A/200204/6192962.html

Zhang Caini, Wang Xiangzhao. Optical methods for measuring small angles[J]. Journal of Optoelectronics?Laser, 2002, 13(4): 416–419. http://www.cqvip.com/qk/92586A/200204/6192962.html

[4] Vasudevan M, Arumugam R, Paramasivam S. Real time implementation of viable torque and flux controllers and torque ripple minimization algorithm for induction motor drive[J]. Energy Conversion and Management, 2006, 47(11–12): 1359–1371. doi: 10.1016/j.enconman.2005.08.013

[5] Li Yingjun, Zhang Jun, Jia Zhenyuan, et al. Research on force-sensing element's spatial arrangement of piezoelectric six-component force/torque sensor[J]. Mechanical Systems and Signal Processing, 2009, 23(8): 2687–2698. doi: 10.1016/j.ymssp.2009.05.014

[6] 张燕君, 王光宇, 付兴虎.长周期光纤光栅-布拉格光纤光栅多波长解调[J].光电工程, 2016, 43(8): 13–17. http://mall.cnki.net/magazine/Article/GDGC201608003.htm

Zhang Yanjun, Wang Guangyu, Fu Xinghu. Multiple wavelength demodulation method of long period fiber grating and fiber Bragg grating[J]. Opto-Electronic Engineering, 2016, 43(8): 13–17. http://mall.cnki.net/magazine/Article/GDGC201608003.htm

[7] 郭伟, 李新良, 宋昊.表面粘贴光纤光栅传感器的应变传递分析[J].计测技术, 2011, 31(4): 1–4. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hkjcjs201104001

Guo Wei, Li Xinliang, Song Hao. Analysis of strain transfer of fiber grating sensors adhered to the structure surface[J]. Metrology & Measurement Technology, 2011, 31(4): 1–4. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hkjcjs201104001

[8] 麦明仁, 陈维平, 屈盛官, 等.金属粉末压制过程侧压应力直接测试系统的研究[J].现代制造工程, 2009, 13(2): 15–18. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=xxgy200902003&dbname=CJFD&dbcode=CJFQ

Mai Mingren, Chen Weiping, Qu Shengguan, et al. Investigation on side pressure's test mode of metal powder during compaction[J]. Modern Manufacturing Engineering, 2009, 13(2): 15–18. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=xxgy200902003&dbname=CJFD&dbcode=CJFQ

[9] 张燕君, 田永胜, 付兴虎, 等.可调量程拉绳式光纤布拉格光栅位移传感器[J].光电工程, 2017, 44(6): 626-632. http://www.oejournal.org/J/OEE/Article/Details/A170830000052/CN

Zhang Yanjun, Tian Yongsheng, Fu Xinghu, et al. The adjustable range draw-wire type fiber Bragg grating displacement sensor[J]. Opto-Electronic Engineering, 2017, 44(6): 626-632. http://www.oejournal.org/J/OEE/Article/Details/A170830000052/CN

[10] Dias G L, Magalhães R R, Ferreira D D, et al. The use of a robotic arm for displacement measurements in a cantilever beam[J]. International Journal of Manufacturing, Materials, and Mechanical Engineering, 2016, 6(3): 45–57. doi: 10.4018/IJMMME

[11] 樊星, 赵美蓉, 黄银国, 等.一种基于光纤光栅的双月牙弧轮辐式扭矩传感器[J].世界科技研究与发展, 2014, 36(3): 231–235. http://edu.wanfangdata.com.cn/Periodical/Detail/sjkjyjyfz201403004

Fan Xing, Zhao Meirong, Huang Yinguo, et al. A double crescent-shaped spoke type torque sensor based on fiber bragg grating[J]. World Sci-Tech R & D, 2014, 36(3): 231–235. http://edu.wanfangdata.com.cn/Periodical/Detail/sjkjyjyfz201403004

[12] 李俊, 吴瑾, 高俊启.一种监测钢筋腐蚀的光纤光栅传感器的研究[J].光谱学与光谱分析, 2010, 30(1): 283–286. http://d.wanfangdata.com.cn/Periodical_gpxygpfx201001067.aspx

Li Jun, Wu Jin, Gao Junqi. Study of an optical fiber grating sensor for monitoring corrosion of reinforcing steel[J]. Spectroscopy and Spectral Analysis, 2010, 30(1): 283–286. http://d.wanfangdata.com.cn/Periodical_gpxygpfx201001067.aspx

[13] 温昌金, 李玉龙.一种光纤光栅施加预应力的管式封装装置[J].光通信技术, 2014, 38(6): 12–15. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gtxjs201406004

Wen Changjin, Li Yulong. Prestress capillary encapsulating device of fiber Bragg grating[J]. Optical Communication Tech-nology, 2014, 38(6): 12–15. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gtxjs201406004

[14] 李海星, 丁亚林, 惠守文, 等.单轴柔性铰链柔度系数试验装置的设计[J].光学精密工程, 2011, 19(7): 1552–1559.

Li Haixing, Ding Yalin, Hui Shouwen, et al. Design of compliance factor experiment setup for single-axis flexure hinge[J]. Optics and Precision Engineering, 2011, 19(7): 1552–1559.

[15] Liu Qinpeng, Jia Zhen'an, Fu Haiwei, et al. Double cantilever beams accelerometer using short fiber Bragg grating for eliminating chirp[J]. IEEE Sensors Journal, 2016, 16(17): 6611–6616. http://ieeexplore.ieee.org/document/7506242/

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: