-

摘要:

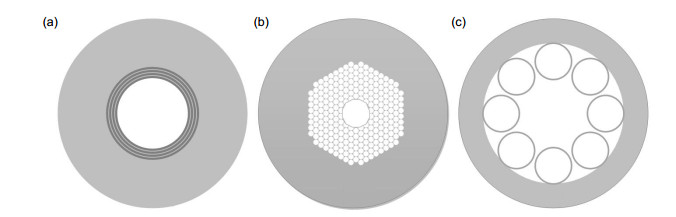

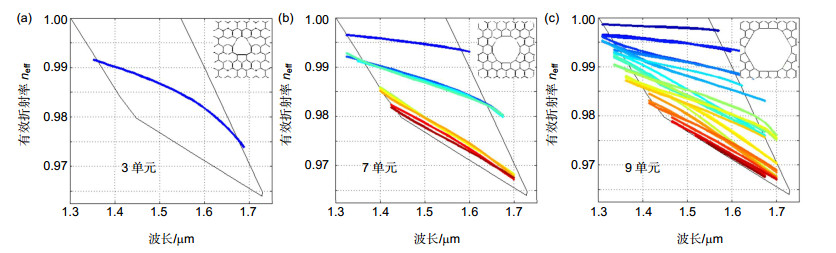

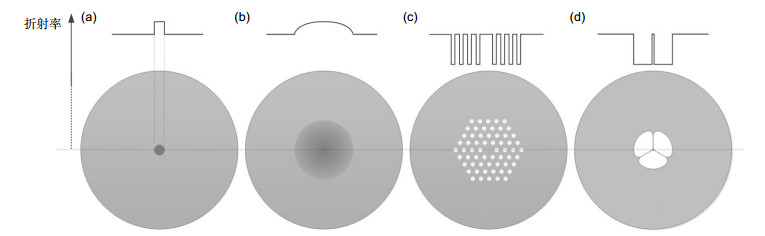

本文综述了空芯光子带隙光纤的独特性质,并介绍了近年来这类光纤在传感领域应用的新进展。光波在空气纤芯中低损耗传输是空芯光子带隙光纤的重要特性,它带来了长距离、大能量密度的光与物质相互作用通道,降低了光纤材料属性对传输光的影响(如中红外吸收、热光效应),为诸如痕量气体/液体探测、高精度光纤陀螺仪等传感应用提供了高效的新平台。空芯光子带隙光纤内部精细的微结构具有新颖的机械性能和热性能,有利于诸如声波、振动探测等传感应用;还可结合光纤后期热处理、选择性填充等技术,对多孔包层进行结构修改或材料填充,获得进一步的性能和功能扩展。这些灵活性已用于开发具有新特性的光纤器件,例如光栅、起偏器和偏振干涉仪。目前,空芯光子带隙光纤传感技术的发展已大大扩展了光纤的环境感知能力和应用范围,是全光器件和光集成技术发展的重要方向。

Abstract:In this paper, the unique properties of the hollow-core photonic bandgap fiber (HC-PBF) are reviewed, and a variety of sensing and device applications of this type of fiber in recent years are introduced. Low-loss light transmission in air core is an important characteristic of the HC-PBF, which provides light-matter interaction channel with high energy density and long interaction distance. In addition, the air-propagation of the light in fiber also reduces the impacts of fiber material properties (such as infrared absorption, thermos-optical effect) on propagating light, hence offers an efficient platform for the sensing applications such as trace gas/liquid detection, optical fiber gyro sensing. The fine micro-structure in HC-PBF exhibits novel mechanical and thermal properties, which would be beneficial to the sensing applications such as sound wave and vibration detection. The HC-PBF's porous structure can also be locally modified by using various post-processing techniques, such as local heat treatment, micromachining and selective filling, which would enable further function extension or performance enhancement. The flexibility of the fiber has been used to develop new optical fiber devices, such as grating, polarizer and polarization interferometer. At present, the development of HC-PBF sensing technology has greatly expanded the sensing ability and application range of optical fiber. It is an important direction for the development of all-optical devices and optical integration technology.

-

Key words:

- hollow-core fiber /

- photonic bandgap fiber /

- optical fiber sensor /

- gas sensor /

- distributed gas sensing

-

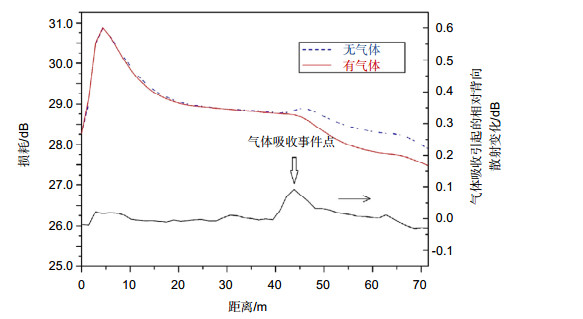

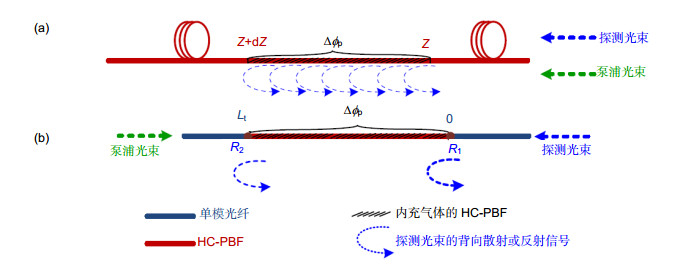

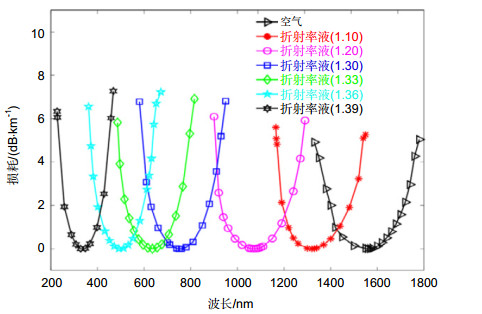

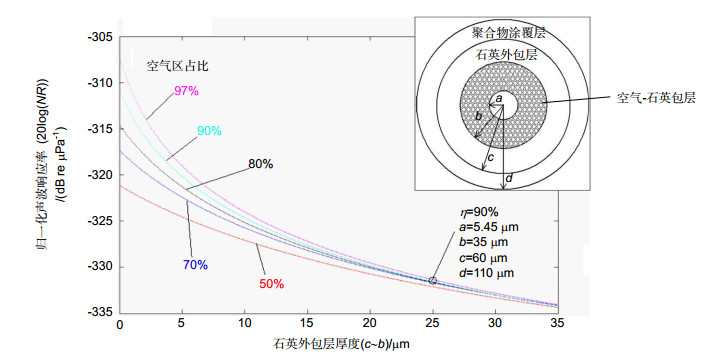

Overview: In this paper, the unique properties and some recent sensing applications of hollow-core photonic bandgap fibers (HC-PBFs) are reviewed. Different to conventional all-solid fibers based on the principle of total internal reflection, in HC-PBF, most of light propagates in a hollow core region inside the fiber (typically > 95%). Hence, the core region of HC-PBF can be a contamination-free light-matter interaction channel with low loss, high energy density and long interaction distance. The air-propagation of light in HC-PBF would also reduces the impacts of fiber material properties (such as infrared absorption, thermos-optical effect) on the propagating light, hence offers an efficient platform for the sensing applications such as trace gas/liquid detection, optical fiber gyro sensing. Many high-sensitive single point and distributed/quasi-distributed gas sensing techniques based on HC-PBFs have been developed in recent years. Based on a photothermal interferometric detection method, the near-infrared HC-PBF acetylene sensing system can reach a detection limit of few ppb (parts per billion) level in noise equivalent concentration, and a dynamic range of about six orders of magnitude. The response time of long HC-PBF gas sensing systems can be improved by drilling side-holes along the fiber by using femtosecond laser. The average loss of the holes has been optimized to about 10-2 dB per hole. Liquids with different properties can be filled in the core or cladding region for a functional modification or extension. For example, the bandgap of HC-PBF can be adjusted by filling the liquid with specific refractive-index into the fiber. The fine silica-structure in HC-PBF exhibits novel mechanical and thermal properties, which would be beneficial to the sensing applications such as sound wave and vibration detection. The HC-PBF's porous structure can also be locally modified by applying various post-processing techniques, such as local heat treatment, micro-machining and selective filling. This would enable building novel in-fiber devices, for example long period gratings, polarizer and polarization interferometer et al. At present, the development of HC-PBF sensing technology has greatly expanded the sensing ability and application range of optical fiber. It is an important direction for the development of all optical devices and optical integration technology.

-

-

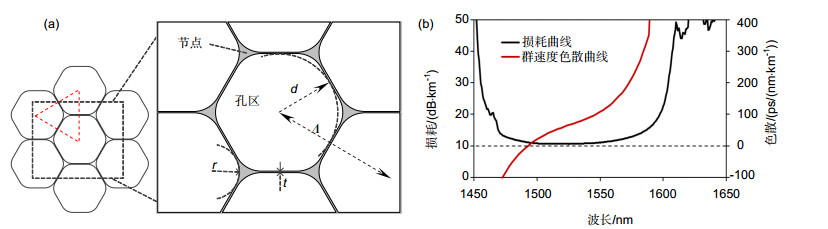

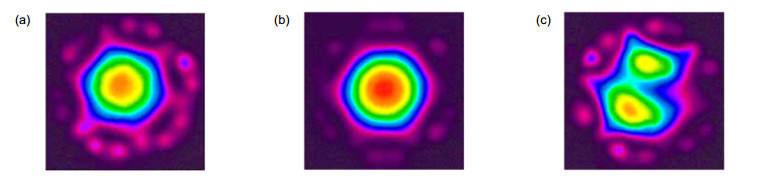

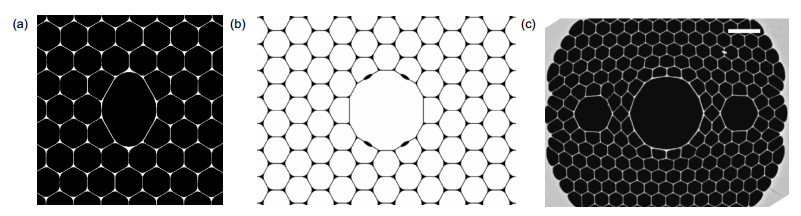

图 5 实测7单元HC-PBF在不同光纤长度和入射偏移时的输出模场形态。(a)长L=5 m,相对偏移Δξ=0;(b)长L=35 m,相对偏移Δξ=0;(c)长L=5 m,相对偏移Δξ≈0.5。相对偏移Δξ定义为绝对偏移量除以空芯尺寸[8]

Figure 5. The measured mode distribution of 7-cell HC-PBFs with different fiber length and incident offsets. (a) Fiber length L=5 m, relative offset Δξ=0; (b) Fiber length L=35 m, relative offset Δξ=0; (c) Fiber length L=5 m, relative offset Δξ≈0.5[8]

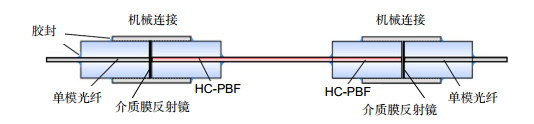

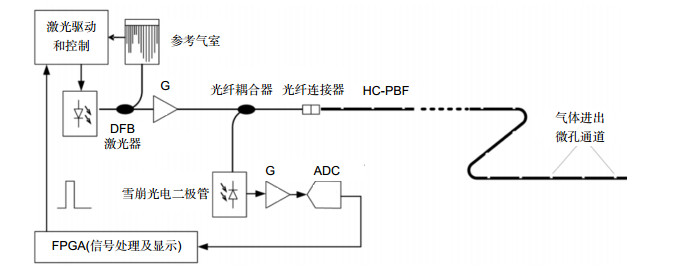

图 8 基于空芯光子带隙光纤的光纤光热干涉气体探测系统。OC:环行器;FC:耦合器;PD:光探测器;HPF/LPF:高/低通滤波器;DAQ:数据采集卡;PZT:压电陶瓷驱动环[26]

Figure 8. Fiber optic thermal interference gas detection system based on HC-PBF. OC: optical circulator. FC: fiber coupler. PD: power detector. HPF/LPF: high/low pass filter. DAQ: data acquisition device. PZT: piezoelectric element[26]

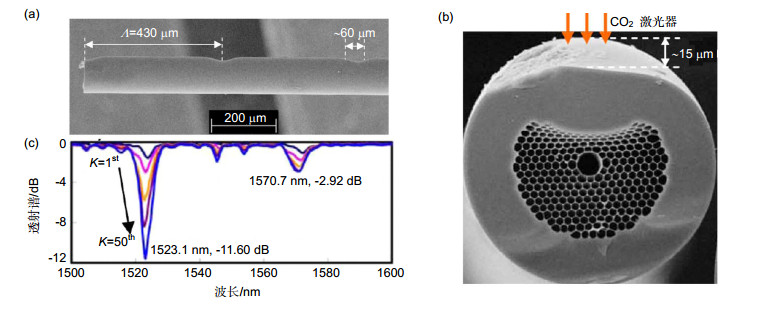

图 15 (a) HC-PBF上用二氧化碳激光制备的周期430 μm的LPG局部侧视图;(b) HC-PBF LPG在节点(凹槽)处的截面图;(c)一个HC-PBF LPG样品透射谱的增长图[59]

Figure 15. (a) Side-view image of a 430 μm-pitch HC-PBF LPG made by CO2 laser; (b) The cross-sectional image of a HC-PBF LPG at the grooves; (c) The growth of the transmission spectrum of a HC-PBF LPG sample during fabrication[59]

图 16 (a) 全光纤偏振计结构示意图;(b) HC-PBF上光纤起偏器样品侧视照片,及对应HC-PBF上(c)未加工和(d)加工位置处的截面照片;(e) 531 mm长偏振计的透射光谱;(f) 147 mm长偏振计对扭曲率的响应[62]

Figure 16. (a) Schematic structure of an all fiber polarimeter; (b) The side-view photo of a optical fiber polarizer in a HC-PBF polarimeter, and the cross-section photos corresponding to (c) the unprocessed and (d) the processed positions; (e) The transmission spectra of a 531-mm-length polarimeter; (f) The response of a 147 mm long polarimeter to the twist rate[62]

-

[1] Russell P. Photonic crystal fibers[J]. Science, 2003, 299(5605): 358-362. doi: 10.1126/science.1079280

[2] Poletti F, Wheeler N V, Petrovich M N, et al. Towards high-capacity fibre-optic communications at the speed of light in vacuum[J]. Nature Photonics, 2013, 7(4): 279-284. doi: 10.1038/nphoton.2013.45

[3] Cregan R F, Mangan B J, Knight J C, et al. Single-mode photonic band gap guidance of light in air[J]. Science, 1999, 285(5433): 1537-1539. doi: 10.1126/science.285.5433.1537

[4] Poletti F, Petrovich M N, Richardson D J. Hollow-core photonic bandgap fibers: technology and applications[J]. Nanophotonics, 2013, 2(5-6): 315-340. http://d.old.wanfangdata.com.cn/Periodical/gxydljqyyjs200606001

[5] Poletti F. Hollow core fiber with an octave spanning bandgap[J]. Optics Letters, 2010, 35(17): 2837-2839. doi: 10.1364/OL.35.002837

[6] Hollow-core photonic bandgap fiber (model HC-1550) datasheet from website of NKT Photonics Corporation[OL]. https://www.nktphotonics.com/lasers-fibers/product/hollow-core-photonic-crystal-fibers/.

[7] Roberts P J, Couny F, Sabert H, et al. Ultimate low loss of hollow-core photonic crystal fibres[J]. Optics Express, 2005, 13(1): 236-244. doi: 10.1364/OPEX.13.000236

[8] Petrovich M N, Poletti F, Van Brakel A, et al. Robustly single mode hollow core photonic bandgap fiber[J]. Optics Express, 2008, 16(6): 4337-4346. doi: 10.1364/OE.16.004337

[9] Digonnet M J F, Kim H K, Kino G S, et al. Understanding air-core photonic-bandgap fibers: analogy to conventional fibers[J]. Journal of Lightwave Technology, 2006, 23(12): 4169-4177. http://ieeexplore.ieee.org/document/1566743

[10] Fini J M, Nicholson J W, Mangan B, et al. Polarization maintaining single-mode low-loss hollow-core fibres[J]. Nature Communications, 2014, 5: 5085. doi: 10.1038/ncomms6085

[11] Kim H K, Shin J, Fan S H, et al. Designing air-core photonic-bandgap fibers free of surface modes[J]. IEEE Journal of Quantum Electronics, 2004, 40(5): 551-556. doi: 10.1109/JQE.2004.826429

[12] West J A, Smith C M, Borrelli N F, et al. Surface modes in air-core photonic band-gap fibers[J]. Optics Express, 2004, 12(8): 1485-1496. doi: 10.1364/OPEX.12.001485

[13] Yang F, Jin W, Cao Y C, et al. Towards high sensitivity gas detection with hollow-core photonic bandgap fibers[J]. Optics Express, 2014, 22(20): 24894-24907. doi: 10.1364/OE.22.024894

[14] Fini J M, Nicholson J W, Windeler R S, et al. Low-loss hollow-core fibers with improved single-modedness[J]. Optics Express, 2013, 21(5): 6233-6242. doi: 10.1364/OE.21.006233

[15] Wegmuller M, Legré M, Gisin N, et al. Experimental investigation of the polarization properties of a hollow core photonic bandgap fiber for 1550 nm[J]. Optics Express, 2005, 13(5): 1457-1467. doi: 10.1364/OPEX.13.001457

[16] Poletti F, Broderick N G R, Richardson D J, et al. The effect of core asymmetries on the polarization properties of hollow core photonic bandgap fibers[J]. Optics Express, 2005, 13(22): 9115-9124. doi: 10.1364/OPEX.13.009115

[17] Bouwmans G, Luan F, Knight J C, et al. Properties of a hollow-core photonic bandgap fiber at 850 nm wavelength[J]. Optics Express, 2003, 11(14): 1613-1620. doi: 10.1364/OE.11.001613

[18] Wen H, Terrel M A, Kim H K, Digonnet M J F, Fan S, Measurements of the Birefringence and Verdet Constant in an Air-Core Fiber[J]. Journal of Lightwave Technology, 2009, 27(15): 3194-3101. doi: 10.1109/JLT.2008.2009546

[19] Alam M S, Saitoh K, Koshiba M. High group birefringence in air-core photonic bandgap fibers[J]. Optics Letters, 2005, 30(8): 824-826. doi: 10.1364/OL.30.000824

[20] Roberts P J, Williams D P, Sabert H, et al. Design of low-loss and highly birefringent hollow-core photonic crystal fiber[J]. Optics Express, 2006, 14(16): 7329-7341. doi: 10.1364/OE.14.007329

[21] Hansen T P, Broeng J, Jakobsen C, et al. Air-guiding photonic bandgap fibers: spectral properties, macrobending loss, and practical handling[J]. Journal of Lightwave Technology, 2004, 22(1): 11-15. doi: 10.1109/JLT.2003.822833

[22] Wheeler N V, Heidt A M, Baddela N K, et al. Low-loss and low-bend-sensitivity mid-infrared guidance in a hollow-core-photonic-bandgap fiber[J]. Optics Letters, 2014, 39(2): 295-298. doi: 10.1364/OL.39.000295

[23] Slavík R, Marra G, Fokoua E N, et al. Ultralow thermal sensitivity of phase and propagation delay in hollow core optical fibres[J]. Scientific Reports, 2015, 5: 15447. doi: 10.1038/srep15447

[24] Dangui V, Kim H K, Digonnet M J F, et al. Phase sensitivity to temperature of the fundamental mode in air-guiding photonic-bandgap fibers[J]. Optics Express, 2005, 13(18): 6669-6684. doi: 10.1364/OPEX.13.006669

[25] Jones D C, Bennett C R, Smith M A, et al. High-power beam transport through a hollow-core photonic bandgap fiber[J]. Optics Letters, 2014, 39(11): 3122-3125. doi: 10.1364/OL.39.003122

[26] Jin W, Cao Y C, Yang F, et al. Ultra-sensitive all-fibre photothermal spectroscopy with large dynamic range[J]. Nature Communications, 2015, 6: 6767. doi: 10.1038/ncomms7767

[27] Hoo Y L, Jin W, Ho H L, et al. Gas diffusion measurement using hollow-core photonic bandgap fiber[J]. Sensors and Actuators B: Chemical, 2005, 105(2): 183-186. doi: 10.1016/j.snb.2004.05.059

[28] Ritari T, Tuominen J, Ludvigsen H, et al. Gas sensing using air-guiding photonic bandgap fibers[J]. Optics Express, 2004, 12(17): 4080-4087. doi: 10.1364/OPEX.12.004080

[29] Magalhaes F, Carvalho J P, Ferreira L A, et al. Methane detection system based on wavelength modulation spectroscopy and hollow-core fibres[C]//Proceedings of 2008 IEEE SENSORS, 2008: 1277-1280.

[30] Parry J P, Griffiths B C, Gayraud N, et al. Towards practical gas sensing with micro-structured fibres[J]. Measurement Science and Technology, 2009, 20(7): 075301. doi: 10.1088/0957-0233/20/7/075301

[31] Wynne R M, Barabadi B, Creedon K J, et al. Sub-minute response time of a hollow-core photonic bandgap fiber gas sensor[J]. Journal of Lightwave Technology, 2009, 27(11): 1590-1596. doi: 10.1109/JLT.2009.2019258

[32] Nwaboh J A, Hald J, Lyngsø J K, et al. Measurements of CO2 in a multipass cell and in a hollow-core photonic bandgap fiber at 2 μm[J]. Applied Physics B, 2013, 110(2): 187-194. doi: 10.1007/s00340-012-5047-0

[33] Benabid F, Couny F, Knight J C, et al. Compact, stable and efficient all-fibre gas cells using hollow-core photonic crystal fibres[J]. Nature, 2005, 434(7032): 488-491. doi: 10.1038/nature03349

[34] Xiao L M, Demokan M S, Jin W, et al. Fusion splicing photonic crystal fibers and conventional single-mode fibers: microhole collapse effect[J]. Journal of Lightwave Technology, 2007, 25(11): 3563-3574. doi: 10.1109/JLT.2007.907787

[35] Benabid F. Photonic microcells[C]//Proceedings of Advanced Photonics Congress, 2012.

[36] Hoo Y L, Liu S J, Ho H L, et al. Fast response microstructured optical fiber methane sensor with multiple side-openings[J]. IEEE Photonics Technology Letters, 2010, 22(5): 296-298. doi: 10.1109/LPT.2009.2039016

[37] Lehmann H, Brueckner S, Kobelke J, et al. Toward photonic crystal fiber based distributed chemosensors[J]. Proceedings of the SPIE, 2005, 5855: 419-422. doi: 10.1117/12.623667

[38] Li X F, Liang J X, Oigawa H, et al. Doubled optical path length for photonic bandgap fiber gas cell using micromirror[J]. Japanese Journal of Applied Physics, 2011, 50(6): 06GM01. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ0235605689

[39] van Brakel A, Grivas C, Petrovich M N, et al. Micro-channels machined in microstructured optical fibers by femtosecond laser[J]. Optics Express, 2007, 15(14): 8731-8736. doi: 10.1364/OE.15.008731

[40] Yang F, Jin W, Lin Y C, et al. Hollow-core microstructured optical fiber gas sensors[J]. Journal of Lightwave Technology, 2017, 35(16): 3413-3424. doi: 10.1109/JLT.2016.2628092

[41] Lin Y C, Wei J, Yang F, et al. Pulsed photothermal interferometry for spectroscopic gas detection with hollow-core optical fibre[J]. Scientific Reports, 2016, 6: 39410. doi: 10.1038/srep39410

[42] Tan Y Z, Jin W, Yang F, et al. Hollow-core fiber-based high finesse resonating cavity for high sensitivity gas detection[J]. Journal of Lightwave Technology, 2017, 35(14): 2887-2893. doi: 10.1109/JLT.2017.2705229

[43] Yang F, Jin W. All-fiber hydrogen sensor based on stimulated Raman gain spectroscopy with a 1550 nm hollow-core fiber[C]//Proceedings of 25th Optical Fiber Sensors Conference (OFS), 2017: 4.

[44] Bao X Y, Chen L. Recent progress in distributed fiber optic sensors[J]. Sensors, 2012, 12(7): 8601-8639. doi: 10.3390/s120708601

[45] Jin W, Ho H L, Cao Y C, et al. Gas detection with micro- and nano-engineered optical fibers[J]. Optical Fiber Technology, 2013, 19(6): 741-759. doi: 10.1016/j.yofte.2013.08.004

[46] Lin Y C, Liu F, He X G, et al. Distributed gas sensing with optical fibre photothermal interferometry[J]. Optics Express, 2017, 25(25): 31568-31585. doi: 10.1364/OE.25.031568

[47] Xiao L M, Jin W, Demokan M S, et al. Fabrication of selective injection microstructured optical fibers with a conventional fusion splicer[J]. Optics Express, 2005, 13(22): 9014-9022. doi: 10.1364/OPEX.13.009014

[48] Cordeiro C M B, dos Santos E M, Cruz C H B, et al. Lateral access to the holes of photonic crystal fibers-selective filling and sensing applications[J]. Optics Express, 2006, 14(18): 8403-8412. doi: 10.1364/OE.14.008403

[49] Huang Y Y, Xu Y, Yariv A. Fabrication of functional microstructured optical fibers through a selective-filling technique[J]. Applied Physics Letters, 2004, 85(22): 5182-5184. doi: 10.1063/1.1828593

[50] Bozolan A, Gerosa R M, de Matos C J S, et al. Temperature sensing using colloidal-core photonic crystal fiber[J]. IEEE Sensors Journal, 2012, 12(1): 195-200. doi: 10.1109/JSEN.2011.2146771

[51] Du F, Lu Y Q, Wu S T. Electrically tunable liquid-crystal photonic crystal fiber[J]. Applied Physics Letters, 2004, 85(12): 2181-2183. doi: 10.1063/1.1796533

[52] Yan D, Popp J, Pletz M W, et al. Highly sensitive broadband Raman sensing of antibiotics in step-index hollow-core photonic crystal fibers[J]. ACS Photonics, 2017, 4(1): 138-145. doi: 10.1021/acsphotonics.6b00688

[53] Xuan H F, Jin W, Ju W, et al. Low-contrast photonic bandgap fibers and their potential applications in liquid-base sensors[J]. Proceedings of SPIE, 2007, 6619: 661936. https://www.researchgate.net/publication/253474494_Low-contrast_photonic_bandgap_fibers_and_their_potential_applications_in_liquid-base_sensors

[54] de Matos C J S, Cordeiro C M B, dos Santos E M, et al. Liquid-core, liquid-cladding photonic crystal fibers[J]. Optics Express, 2007, 15(18): 11207-11212. doi: 10.1364/OE.15.011207

[55] Wang Y P, Tan X L, Jin W, et al. Improved bending property of half-filled photonic crystal fiber[J]. Optics Express, 2010, 18(12): 12197-12202. doi: 10.1364/OE.18.012197

[56] Pang M, Xuan H F, Ju J, et al. Influence of strain and pressure to the effective refractive index of the fundamental mode of hollow-core photonic bandgap fibers[J]. Optics Express, 2010, 18(13): 14041-14055. doi: 10.1364/OE.18.014041

[57] Pang M, Jin W. Detection of acoustic pressure with hollow-core photonic bandgap fiber[J]. Optics Express, 2009, 17(13): 11088-11097. doi: 10.1364/OE.17.011088

[58] Yang F, Jin W, Ho H L, et al. Enhancement of acoustic sensitivity of hollow-core photonic bandgap fibers[J]. Optics Express, 2013, 21(13): 15514-15521. doi: 10.1364/OE.21.015514

[59] Wang Y P, Jin W, Ju J, et al. Long period gratings in air-core photonic bandgap fibers[J]. Optics Express, 2008, 16(4): 2784-2790. doi: 10.1364/OE.16.002784

[60] Iadicicco A, Ranjan R, Campopiano S. Fabrication and characterization of long-period gratings in hollow core fibers by electric arc discharge[J]. IEEE Sensors Journal, 2015, 15(5): 3014-3020. doi: 10.1109/JSEN.2014.2383175

[61] Xuan H F, Jin W, Ju J, et al. Hollow-core photonic bandgap fiber polarizer[J]. Optics Letters, 2008, 33(8): 845-847. doi: 10.1364/OL.33.000845

[62] Xuan H F, Jin W, Zhang M, et al. In-fiber polarimeters based on hollow-core photonic bandgap fibers[J]. Optics Express, 2009, 17(15): 13246-13254. doi: 10.1364/OE.17.013246

[63] Bykov D S, Schmidt O A, Euser T G, et al. Flying particle sensors in hollow-core photonic crystal fibre[J]. Nature Photonics, 2015, 9: 461-465. doi: 10.1038/nphoton.2015.94

[64] Digonnet M, Blin S, Kim H K, et al. Sensitivity and stability of an air-core fiber-optic gyroscope[J]. Measurement Science & Technology, 2007, 18(10): 3089-3097. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=Open J-Gate000001781255

[65] Ying D, Demokan M S, Zhang X, et al. Analysis of Kerr effect in resonator fiber optic gyros with triangular wave phase modulation[J]. Applied Optics, 2010, 49(3): 529-535. doi: 10.1364/AO.49.000529

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: