-

摘要:

残余应力是光学元件的一个重要性能参数,对光学元件的制造和使用意义重大。光学元件残余应力的无损检测方法可粗略概括为两大类:一类是基于应变的测量方法,包括X射线衍射法、Stoney曲率法和显微拉曼光谱法,这些方法基于晶体和弹性力学分析方法,发展成熟、应用广泛;另一类是基于应力双折射效应的测量方法,包括数字光弹法、光弹调制器法和偏振光腔衰荡法,都是对残余应力导致的双折射相位差的测量,具有更直接的光学关联性、测量精度高的特点。本文归纳了光学元件残余应力测量的几种常见方法的测量原理、测量精度和应用场景,对比了它们的性能并分析了它们之间的关联性,以期建立起光学元件残余应力无损检测的宏观印象。

Abstract:Residual stress is an important performance indicator of optics, which is of great significance to the fabrications and applications of optical components. Residual stress measurement methods of optics can be summed up into two categories: methods based on the strain measurement and on the stress induced birefringence measurement, respectively. The strain based methods, which are built upon crystal dynamics and elastic mechanics, including X-ray diffraction (XRD), Stoney curvature method, and micro-Raman spectroscopic method, are well developed and widely used. Methods based on the measurements of birefringence phase retardation induced by residual stress, including digital photoelasticity method, photoelasticitic modulator (PEM) method and polarization-dependent cavity ring-down method, show a higher precision. The principles, measurement precisions and application scenarios of these residual stress measurement methods are summarized in this overview. Comparisons between the performances of these methods are performed and correlations between them are analyzed in detail.

-

Key words:

- optics /

- residual stress /

- birefringence /

- strain

-

Overview: Residual stress is an important performance indicator of optics, which is of great significance to the fabrications and applications of optical components. Residual stress measurement methods of optics can be summed up into two categories: methods based on strain measurement and on stress induced birefringence measurement, respectively.

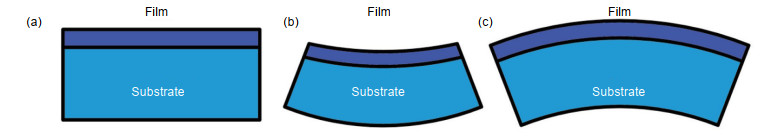

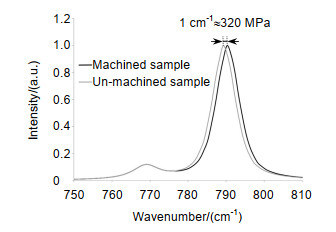

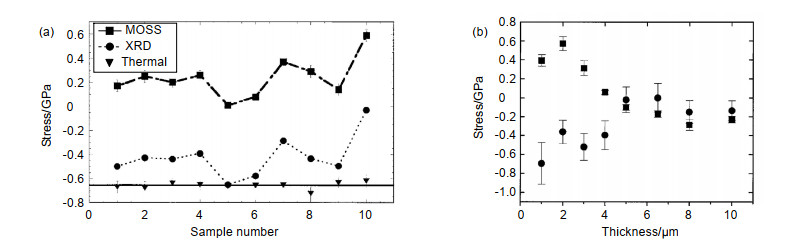

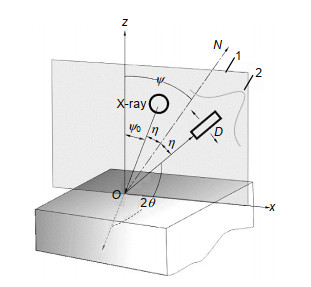

The strain based methods, which are built upon crystal dynamics and elastic mechanics, including X-ray diffraction (XRD), Stoney curvature method, and micro-Raman spectroscopic method, are well developed and widely used. XRD method is the standard residual stress measurement for crystal materials, which is based on the Bragg diffraction of X-rays caused by crystalline lattice. By comparing the lattice distance of stressed and stress-free materials, the residual stress can be precisely determined. The uncertainty of XRD is about ±10 MPa. Stoney curvature method is commonly used for evaluating residual stress in optical thin films. The difference of thermal expansion coefficients between coatings and substrate results in a substrate curvature change after deposition. The measurement precision of Stoney curvature method is about several tens of MPa and is greatly influenced by film/substrate thickness ratio and overall stress uniformity. Micro-Raman spectroscopic method is based on a liner relationship between Raman shift and residual stress of Raman-sensitive materials. The determination of residual stress requires corresponding stress-free reference materials. The measurement precision of Raman spectroscopic method can reach ±10 MPa when the temperature is stabilized.

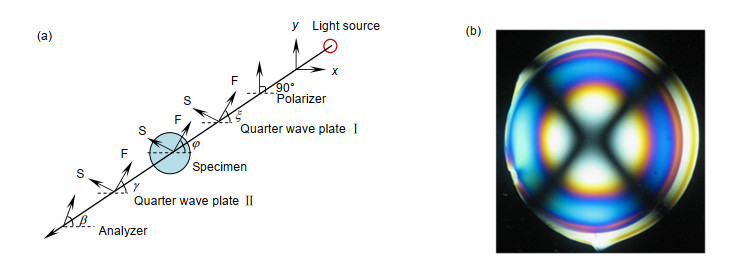

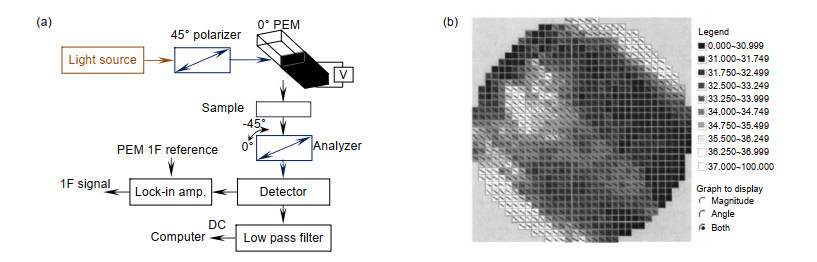

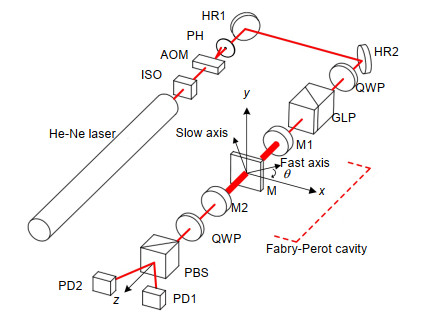

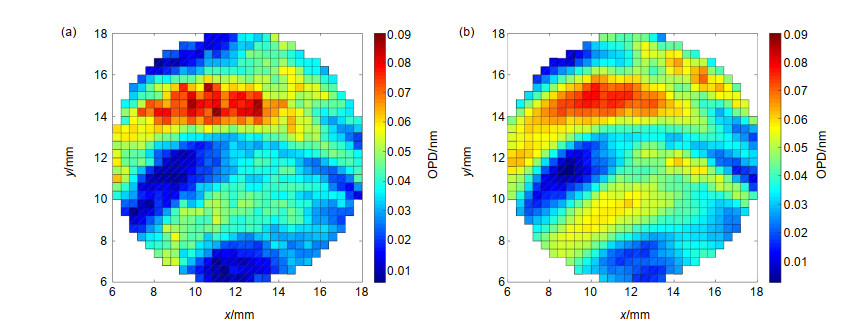

Methods based on residual stress induced birefringence phase retardation, including digital photoelasticity method, photoelasticitic modulator (PEM) method and polarization-dependent cavity ring-down (CRD) method, show a higher measurement precision. Digital photoelasticity method which combining polariscope and CCD image processing, is convenient for stress birefringence mapping. Analyzing of isoclinic fringe and isochromatic fringe is key to high precision measurement of birefringence phase difference. The measurement precision of ±0.03 MPa is reached. PEM method is based on periodic modulation of incident polarization in polariscope. Double detection channels and differential data processing scheme improve the measurement precision to ±0.2 kPa. Polarization-dependent CRD method is newly adopted to the measurement of residual stress birefringence of fused silica substrates. Intracavity birefringence caused s- and p- polarization of ring-down decays to oscillate with frequency linearly related to the birefringence phase difference. Polarization-dependent CRD method reaches a measurement precision of ±0.03 kPa, the highest precision for residual stress measurement of optical materials reported to date.

The principles, measurement precisions and application scenarios of these residual stress measurement methods are summarized in this overview. Comparisons between the performances of these methods are performed and correlations between them are analyzed in details.

-

-

表 1 几种光学元件残余应力无损测量方法对比

Table 1. Comparisons of non-destructive residual stress measurement methods of optics

测量方法 适用元件 参考样品 测量 测量精度 横向分辨率 穿透深度 XRD 单晶、多晶、微晶材料元件 需要无应力样品参考 正应力,切应力 ±10 MPa < 10 μm < 30 μm Stoney曲率法 薄膜元件 不需要参考 等双轴正应力 ±10% —— —— 拉曼光谱法 拉曼活性光学材料 需要无应力样品参考 双轴正应力 ±10 MPa < 1 μm 不限 数字光弹法 透明光学材料(透射测量) 不需要参考 主应力差,切应力 ±0.03 MPa < 12 μm 不限 光弹调制器法 透明光学材料(透射测量) 不需要参考 主应力差 ±0.2 kPa < 1 mm 不限 偏振光腔衰荡法 透明光学材料(透射测量) 不需要参考 主应力差 ±0.03 kPa < 1 mm 不限 -

[1] Withers P J, Bhadeshia H K D H. Residual stress. Part 1–measurement techniques[J]. Materials science and Technology, 2001, 17(4): 355–365. doi: 10.1179/026708301101509980

[2] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会.无损检测X射线应力测定方法: GB 7704–2017[S].北京: 中国标准出版社, 2017.

General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration. Non-destructive testing—Practice for residual stress measurement by X-ray: GB 7704–2017[S]. Beijing: China Standard Press, 2017.

[3] 谢俊, 程金树, 陆平, 等. X射线法测量微晶玻璃残余应力的误差分析[J].武汉理工大学学报, 2007, 29(2): 23–25. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=whgydxxb200702007

Xie J, Cheng J S, Lu P, et al. Analysis on errors of measuring residual stress in glass-ceramic with X-ray diffraction[J]. Journal of Wuhan University of Technology, 2007, 29(2): 23–25. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=whgydxxb200702007

[4] Labat S, Gergaud P, Thomas O, et al. Interdependence of elastic strain and segregation in metallic multilayers: An X-Ray diffraction study of (111) Au/Ni multilayers[J]. Journal of Applied Physics, 2000, 87(3): 1172–1181. doi: 10.1063/1.371995

[5] Taylor L N, Brown A K, Pung A J, et al. Continuous-wave laser damage of uniform and nanolaminate hafnia and titania optical coatings[J]. Optics Letters, 2013, 38(21): 4292–4295. doi: 10.1364/OL.38.004292

[6] Klaus M, Genzel C, Holzschuh H. Residual stress depth profiling in complex hard coating systems by X-ray diffraction[J]. Thin Solid Films, 2008, 517(3): 1172–1176. doi: 10.1016/j.tsf.2008.05.018

[7] Prevéy P S. Current applications of X-ray diffraction residual stress measurement[C]//Developments in Materials Characterization Technologies, Materials Park, OH, 1996: 103–110.

[8] Kandil F A, Lord J D, Fry A T, et al. A review of residual stress measurement methods a guide to technique selection[R]. United Kingdom: National Physical Lab., Teddington, 2001.

[9] 于康, 孙亚非, 陈晓江. X射线衍射残余应力测试方法及应用[J].火箭推进, 2015, 41(2): 102–107. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hjtj201502017

Yu K, Sun Y F, Chen X J. Residual stress measurement with X-ray diffraction[J]. Journal of Rocket Propulsion, 2015, 41(2): 102–107. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hjtj201502017

[10] Luo Q, Jones A H. High-precision determination of residual stress of polycrystalline coatings using optimised XRD-sin2ψ technique[J]. Surface and Coatings Technology, 2010, 205(5): 1403–1408. doi: 10.1016/j.surfcoat.2010.07.108

[11] Pureza J M, Lacerda M M, De Oliveira A L, et al. Enhancing accuracy to Stoney equation[J]. Applied Surface Science, 2009, 255(12): 6426–6428. doi: 10.1016/j.apsusc.2009.01.097

[12] Janssen G C A M, Abdalla M M, Van Keulen F, et al. Celebrating the 100th anniversary of the Stoney equation for film stress: Developments from polycrystalline steel strips to single crystal silicon wafers[J]. Thin Solid Films, 2009, 517(6): 1858–1867. doi: 10.1016/j.tsf.2008.07.014

[13] Richter F, Kupfer H, Schlott P, et al. Optical properties and mechanical stress in SiO2/Nb2O5 multilayers[J]. Thin Solid Films, 2001, 389(1–2): 278–283. doi: 10.1016/S0040-6090(01)00864-1

[14] 王小增. Al2O3衬底上GaN薄膜热应力和变形极差分析[J].激光与光电子学进展, 2015, 52(4): 041602. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jgygdzxjz201504019

Wang X Z. Range analysis of thermal stress and displacement of GaN films on Al2O3 substrate[J]. Laser & Optoelectronics Progress, 2015, 52(4): 041602. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jgygdzxjz201504019

[15] Rats D, Poitras D, Soro J M, et al. Mechanical properties of plasma-deposited silicon-based inhomogeneous optical coatings[J]. Surface and Coatings Technology, 1999, 111(2–3): 220–228. doi: 10.1016/S0257-8972(98)00812-3

[16] Lee Y Y, McNallan M J. Ignition of nickel in environments containing oxygen and chlorine[J]. Metallurgical Transactions A, 1991, 18(6): 1099–1107. doi: 10.1007/BF02668559

[17] Fluri A, Pergolesi D, Roddatis V, et al. In situ stress observation in oxide films and how tensile stress influences oxygen ion conduction[J]. Nature Communications, 2016, 7(1): 10692. doi: 10.1038/ncomms10692

[18] 邵淑英, 范正修, 范瑞瑛, 等.薄膜应力研究[J].激光与光电子学进展, 2005, 42(1): 22–27. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jgygdzxjz200501007

Shao S Y, Fan Z X, Fan R Y, et al. A review of study of stress in thin films[J]. Laser & Optoelectronics Progress, 2005, 42(1): 22–27. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jgygdzxjz200501007

[19] Klein C A. How accurate are Stoney's equation and recent modifications[J]. Journal of Applied Physics, 2000, 88(9): 5487–5489. doi: 10.1063/1.1313776

[20] Timoshenko S. Analysis of bi-metal thermostats[J]. Journal of the Optical Society of America, 1925, 11(3): 233–255. doi: 10.1364/JOSA.11.000233

[21] Rich T A. Thermo-mechanics of biometal[J]. General Electric Revenue, 1934, 37(2): 102–105. http://www.researchgate.net/publication/313527611_Thermo-mechanics_of_bimetal

[22] Schäfer J D, Näfe H, Aldinger F. Macro- and microstress analysis in sol-gel derived Pb (ZrxTi1-x) O3 thin films[J]. Journal of Applied Physics, 1999, 85(12): 8023. doi: 10.1063/1.370638

[23] Brenner A, Senderoff S. Calculation of stress in electrodeposits from the curvature of a plated strip[J]. Journal of research of the National Bureau of Standards, 1949, 42: 105–123. doi: 10.6028/jres.042.009

[24] Zhang Y, Wang W H, Greer A L. Making metallic glasses plastic by control of residual stress[J]. Nature Materials, 2006, 5(11): 857–860. doi: 10.1038/nmat1758

[25] Freund L B, Suresh S. Thin Film Materials: Stress, Defect Formation and Surface Evolution[M]. Cambridge: Cambridge University Press, 2004.

[26] 刘佩琳.层状硅电极嵌/脱锂的应力演化研究: 修正的Stoney公式和有限元模拟[D].合肥: 中国科学技术大学, 2017.

Liu P L. The stress evolution of layered Si electrode during lithiation and delithiation: modified Stoney formula and finite element simulation[D]. Hefei: University of Science and Technology of China, 2017.

[27] Nakashima S, Mitani T, Ninomiya M, et al. Raman investigation of strain in Si/SiGe heterostructures: Precise determination of the strain-shift coefficient of Si bands[J]. Journal of Applied Physics, 2006, 99(5): 053512. doi: 10.1063/1.2178396

[28] Li Z P, Zhang F H, Zhang Y, et al. Experimental investigation on the surface and subsurface damages characteristics and formation mechanisms in ultra-precision grinding of SiC[J]. The International Journal of Advanced Manufacturing Technology, 2017, 92(5–8): 2677–2688. doi: 10.1007/s00170-017-0267-4

[29] Groth B P, Langan S M, Haber R A, et al. Relating residual stresses to machining and finishing in silicon carbide[J]. Ceramics International, 2016, 42(1): 799–807. doi: 10.1016/j.ceramint.2015.08.179

[30] Serbena F C, Zanotto E D. Internal residual stresses in glass-ceramics: A review[J]. Journal of Non-Crystalline Solids, 2012, 358(6–7): 975–984. doi: 10.1016/j.jnoncrysol.2012.01.040

[31] Huser T, Hollars C W, Siekhaus W J, et al. Characterization of proton exchange layer profiles in KD2PO4 crystals by micro-Raman spectroscopy[J]. Applied Spectroscopy, 2004, 58(3): 349–351. doi: 10.1366/000370204322886726

[32] Safaie P, Eshaghi A, Bakhshi S R. Optical properties of oxygen doped diamond-like carbon thin films[J]. Journal of Alloys and Compounds, 2016, 672: 426–432. doi: 10.1016/j.jallcom.2016.02.195

[33] Zhao Z W, Xue F, Mao Y J Z, et al. Effects of annealing on the residual stresses distribution and the structural properties of Si core fiber[J]. Optical Fiber Technology, 2018, 41: 193–199. doi: 10.1016/j.yofte.2018.01.016

[34] 岑皓, 王克用.微拉曼光谱法检测非制冷红外焦平面阵列残余应力[J].机械强度, 2015, 37(1): 68–73. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxqd201501013

Cen H, Wang K Y. Residual stress analysis of uncooled infrared focal plane arrays by micro-raman spectroscopy[J]. Journal of Mechanical Strength, 2015, 37(1): 68–73. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxqd201501013

[35] 雷振坤, 仇巍, 亢一澜.微尺度拉曼光谱实验力学[M].北京:科学出版社, 2015.

Lei Z K, Qiu W, Kang Y L. Mciroscale-Raman Spectrum and Experimental Mechanics[M]. Beijing: Science China Press, 2015.

[36] 常文爽, 张丹.拉曼光谱法测量金刚石应力与温度实验研究[J].企业科技与发展, 2015(11): 14–15. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zxqykj201511005

[37] 邱宇, 雷振坤, 亢一澜, 等.微拉曼光谱技术及其在微结构残余应力检测中的应用[J].机械强度, 2004, 26(4): 389–392. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxqd200404008

Qiu Y, Lei Z K, Kang Y L, et al. Micro-raman spectroscopy and its applications to measure residual stress in micro-structure[J]. Journal of Mechanical Strength, 2004, 26(4): 389–392. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxqd200404008

[38] Theocaris P S, Gdoutos E E. Matrix Theory of Photoelasticity[M]. Berlin: Springer, 2013.

[39] De Senarmont H. Sur les modifications que la réflexion spéculaire à la surface des corps métalliques imprime à un rayon de lumière polarisée[J]. Ann. Chim. Phys, 1840, 73: 337–362.

[40] Ramesh K, Ramakrishnan V. Digital photoelasticity of glass: A comprehensive review[J]. Optics and Lasers in Engineering, 2016, 87: 59–74. doi: 10.1016/j.optlaseng.2016.03.017

[41] 雷振坤, 云大真, 亢一澜, 等.数字光弹性法综述[J].实验力学, 2004, 19(4): 393–402. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=sylx200404001

Lei Z K, Yun D Z, Kang Y L, et al. A review of digital photoelasticity[J]. Journal of Experimental Mechanics, 2004, 19(4): 393–402. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=sylx200404001

[42] 计欣华, 邓宗白, 鲁阳.工程实验力学[M]. 2版.北京:机械工业出版社, 2010.

[43] Vivek R, Ramesh K. Residual stress analysis of commercial float glass using digital photoelasticity[J]. International Journal of Applied Glass Science, 2015, 6(4): 419–427. doi: 10.1111/ijag.12106

[44] Jagailloux F, Valle V, Dupré J C, et al. Applied photoelasticity for residual stress measurement inside crystal silicon wafers for solar applications[J]. Strain, 2016, 52(4): 355–368. doi: 10.1111/str.12185

[45] Tao B, Yuan Y, Zhou X L, et al. An integrated solution for compression-molded glass lenses[J]. Proceedings of SPIE, 2016, 10021: 100210H. http://www.researchgate.net/publication/309614603_An_integrated_solution_for_compression-molded_glass_lenses

[46] Wang R P. The image photo-carrier theory and its application to the determination of principal stress direction[J]. Proceedings of SPIE, 1987, 814: 257–262. doi: 10.1117/12.941705

[47] Ramesh K, Deshmukh S S. Three fringe photoelasticity-use of colour image processing hardware to automate ordering of isochromatics[J]. Strain, 1996, 32(3): 79–86. doi: 10.1111/j.1475-1305.1996.tb01006.x

[48] Hillar A, Ainola L, Anton J. Half-fringe phase-stepping with separation of the principal stress directions[J]. Proceedings of the Estonian Academy of Sciences, Engineering, 1999, 5(3): 198–211. http://www.researchgate.net/publication/303169969_Half-fringe_phase-stepping_with_separation_of_the_principal_stress_directions

[49] Briñez J C, Martínez A R, Branch J W. Computational hybrid phase shifting technique applied to digital photoelasticity[J]. Optik, 2018, 157: 287–297. doi: 10.1016/j.ijleo.2017.11.060

[50] 尚伟.定向拉伸工艺增韧有机玻璃若干力学问题的实验研究[D].天津: 天津大学, 2011.

Shang W. Experimental research of several mechanics problems for toughened PMMA by directional stretching process[D]. Tianjin: Tianjin University, 2011.

http://cdmd.cnki.com.cn/Article/CDMD-10056-1012007438.htm [51] Sung P C, Wang W C, Hwang C H, et al. A low-level stress measurement method by integrating white light photoelasticity and spectrometry[J]. Optics & Laser Technology, 2018, 98: 33–45. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dc198dfe15fcbfdb3b54f6ec740e76ee

[52] Guo E H, Liu Y G, Han Y S, et al. Full-field stress determination in photoelasticity with phase shifting technique[J]. Measurement Science and Technology, 2018, 29(4): 045208. doi: 10.1088/1361-6501/aaa7ae

[53] 王志斌, 李克武, 张瑞, 等.基于铌酸锂制作光弹调制器用压电驱动器[J].光学精密工程, 2015, 23(1): 63–69. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201501009

Wang Z B, Li K W, Zhang R, et al. Fabrication of piezoelectric actuator for photoelastic modulator based on lithium niobate[J]. Optics and Precision Engineering, 2015, 23(1): 63–69. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201501009

[54] Wang B L, Oakberg T C. A new instrument for measuring both the magnitude and angle of low level linear birefringence[J]. Review of Scientific Instruments, 1999, 70(10): 3847–3854. doi: 10.1063/1.1150000

[55] Wang B L, Leadbetter A, Freudenthal J, et al. Measuring stress birefringence in small Si samples[J]. Energy Procedia, 2014, 55: 608–617. doi: 10.1016/j.egypro.2014.08.033

[56] Sun L, Edlou S. Low-birefringence lens design for polarization sensitive optical systems[J]. Proceedings of SPIE, 2006, 6289: 62890H. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=CC027505979

[57] Van der Sneppen L, Wiskerke A, Ariese F, et al. Improving the sensitivity of HPLC absorption detection by cavity ring-down spectroscopy in a liquid-only cavity[J]. Analytica Chimica Acta, 2006, 558(1–2): 2–6. doi: 10.1016/j.aca.2005.11.022

[58] Meekhof D M, Vetter P, Majumder P K, et al. High-precision measurement of parity nonconserving optical rotation in atomic lead[J]. Physical Review Letters, 1993, 71(21): 3442–3445. doi: 10.1103/PhysRevLett.71.3442

[59] Abramovici A, Althouse W E, Drever R W P, et al. LIGO: The laser interferometer gravitational-wave observatory[J]. Science, 1992, 256(5055): 325–333. doi: 10.1126/science.256.5055.325

[60] Vallet M, Bretenaker F, Le Floch A, et al. The malus fabry–perot interferometer[J]. Optics communications, 1999, 168(5–6): 423–443. doi: 10.1016/S0030-4018(99)00351-X

[61] Lee J Y, Lee H W, Kim J W, et al. Measurement of ultralow supermirror birefringence by use of the polarimetric differential cavity ringdown technique[J]. Applied Optics, 2000, 39(12): 1941–1945. doi: 10.1364/AO.39.001941

[62] Xiao S L, Li B C, Cui H, et al. Sensitive measurement of stress birefringence of fused silica substrates with cavity ring-down technique[J]. Optics Letters, 2018, 43(4): 843–846. doi: 10.1364/OL.43.000843

[63] Noyan I C, Huang T C, York B R. Residual stress/strain analysis in thin films by X-ray diffraction[J]. Critical Reviews in Solid State and Materials Sciences, 1995, 20(2): 125–177. doi: 10.1080/10408439508243733

[64] Hearne S, Chason E, Han J, et al. Stress evolution during metalorganic chemical vapor deposition of GaN[J]. Applied Physics Letters, 1999, 74(3): 356–358. doi: 10.1063/1.123070

[65] Ferreira N G, Abramof E, Leite N F, et al. Analysis of residual stress in diamond films by x-ray diffraction and micro-Raman spectroscopy[J]. Journal of Applied Physics, 2002, 91(4): 2466–2472. doi: 10.1063/1.1431431

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: