| Citation: | Zhang L, Zhen YQ, Tong LM. Optical micro/nanofiber enabled tactile sensors and soft actuators: A review. Opto-Electron Sci 3, 240005 (2024). doi: 10.29026/oes.2024.240005 |

Optical micro/nanofiber enabled tactile sensors and soft actuators: A review

-

Abstract

As a combination of fiber optics and nanotechnology, optical micro/nanofiber (MNF) is considered as an important multifunctional building block for fabricating various miniaturized photonic devices. With the rapid progress in flexible opto-electronics, MNF has been emerging as a promising candidate for assembling tactile sensors and soft actuators owing to its unique optical and mechanical properties. This review discusses the advances in MNF enabled tactile sensors and soft actuators, specifically, focusing on the latest research results over the past 5 years and the applications in health monitoring, human-machine interfaces, and robotics. Future prospects and challenges in developing flexible MNF devices are also presented. -

-

References

[1] Kireev D, Sel K, Ibrahim B et al. Continuous cuffless monitoring of arterial blood pressure via graphene bioimpedance tattoos. Nat Nanotechnol 17, 864–870 (2022). doi: 10.1038/s41565-022-01145-w [2] Libanori A, Chen GR, Zhao X et al. Smart textiles for personalized healthcare. Nat Electron 5, 142–156 (2022). doi: 10.1038/s41928-022-00723-z [3] Wang G, Badal A, Jia X et al. Development of metaverse for intelligent healthcare. Nat Mach Intell 4, 922–929 (2022). doi: 10.1038/s42256-022-00549-6 [4] Liu YM, Yiu C, Song Z et al. Electronic skin as wireless human-machine interfaces for robotic VR. Sci Adv 8, eabl6700 (2022). doi: 10.1126/sciadv.abl6700 [5] Zhang ZX, Wen F, Sun ZD et al. Artificial intelligence‐enabled sensing technologies in the 5G/internet of things era: from virtual reality/augmented reality to the digital twin. Adv Intell Syst 4, 2100228 (2022). doi: 10.1002/aisy.202100228 [6] Li GH, Sun FQ, Zhao SK et al. Autonomous electroluminescent textile for visual interaction and environmental warning. Nano Lett 23, 8436–8444 (2023). doi: 10.1021/acs.nanolett.3c01653 [7] Shih B, Shah D, Li JX et al. Electronic skins and machine learning for intelligent soft robots. Sci Robot 5, eaaz9239 (2020). doi: 10.1126/scirobotics.aaz9239 [8] Li S, Chen XL, Li XM et al. Bioinspired robot skin with mechanically gated electron channels for sliding tactile perception. Sci Adv 8, eade0720 (2022). doi: 10.1126/sciadv.ade0720 [9] Bao RR, Tao J, Zhao J et al. Integrated intelligent tactile system for a humanoid robot. Sci Bull 68, 1027–1037 (2023). doi: 10.1016/j.scib.2023.04.019 [10] Zhou JY, Shao Q, Tang C et al. Conformable and compact multiaxis tactile sensor for human and robotic grasping via anisotropic waveguides. Adv Mater Technol 7, 2200595 (2022). doi: 10.1002/admt.202200595 [11] Hou B, Yi LY, Li C et al. An interactive mouthguard based on mechanoluminescence-powered optical fibre sensors for bite-controlled device operation. Nat Electron 5, 682–693 (2022). doi: 10.1038/s41928-022-00841-8 [12] Leal-Junior A, Avellar L, Biazi V et al. Multifunctional flexible optical waveguide sensor: on the bioinspiration for ultrasensitive sensors development. Opto-Electron Adv 5, 210098 (2022). doi: 10.29026/oea.2022.210098 [13] Bai HD, Li S, Barreiros J et al. Stretchable distributed fiber-optic sensors. Science 370, 848–852 (2020). doi: 10.1126/science.aba5504 [14] Zhao HC, O'Brien K, Li S et al. Optoelectronically innervated soft prosthetic hand via stretchable optical waveguides. Sci Robot 1, eaai7529 (2016). doi: 10.1126/scirobotics.aai7529 [15] Li TL, Su YF, Zheng H et al. An artificial intelligence-motivated skin-like optical fiber tactile sensor. Adv Intell Syst 5, 2200460 (2023). doi: 10.1002/aisy.202200460 [16] Wang SM, Ni XL, Li LY et al. Noninvasive monitoring of vital signs based on highly sensitive fiber optic mattress. IEEE Sens J 20, 6182–6190 (2020). doi: 10.1109/JSEN.2020.2974313 [17] Massari L, Fransvea G, D’Abbraccio J et al. Functional mimicry of Ruffini receptors with fibre Bragg gratings and deep neural networks enables a bio-inspired large-area tactile-sensitive skin. Nat Mach Intell 4, 425–435 (2022). doi: 10.1038/s42256-022-00487-3 [18] Li LY, Sheng SF, Liu YF et al. Automatic and continuous blood pressure monitoring via an optical-fiber-sensor-assisted smartwatch. PhotoniX 4, 21 (2023). doi: 10.1186/s43074-023-00099-z [19] Guo JJ, Niu MX, Yang CX. Highly flexible and stretchable optical strain sensing for human motion detection. Optica 4, 1285–1288 (2017). doi: 10.1364/OPTICA.4.001285 [20] Harnett CK, Zhao HC, Shepherd RF. Stretchable optical fibers: threads for strain‐sensitive textiles. Adv Mater Technol 2, 1700087 (2017). doi: 10.1002/admt.201700087 [21] Guo JJ, Zhou BQ, Yang CX et al. Stretchable and temperature‐sensitive polymer optical fibers for wearable health monitoring. Adv Funct Mater 29, 1902898 (2019). doi: 10.1002/adfm.201902898 [22] Leber A, Cholst B, Sandt J et al. Stretchable thermoplastic elastomer optical fibers for sensing of extreme deformations. Adv Funct Mater 29, 1802629 (2019). doi: 10.1002/adfm.201802629 [23] Guo JJ, Liu XY, Jiang N et al. Highly stretchable, strain sensing hydrogel optical fibers. Adv Mater 28, 10244–10249 (2016). doi: 10.1002/adma.201603160 [24] Yin MJ, Zhang YX, Yin ZG et al. Micropatterned elastic gold‐nanowire/polyacrylamide composite hydrogels for wearable pressure sensors. Adv Mater Technol 3, 1800051 (2018). doi: 10.1002/admt.201800051 [25] Chen T, Qiao XL, Wei PL et al. Tough gel-fibers as strain sensors based on strain–optics conversion induced by anisotropic structural evolution. Chem Mater 32, 9675–9687 (2020). doi: 10.1021/acs.chemmater.0c03342 [26] Zhang L, Tang Y, Tong LM. Micro-/nanofiber optics: merging photonics and material science on nanoscale for advanced sensing technology. iScience 23, 100810 (2020). doi: 10.1016/j.isci.2019.100810 [27] Li Jh, Chen Jh, Xu F. Sensitive and wearable optical microfiber sensor for human health monitoring. Adv Mater Technol 3, 1800296 (2018). doi: 10.1002/admt.201800296 [28] Zhang L, Pan J, Zhang Z et al. Ultrasensitive skin-like wearable optical sensors based on glass micro/nanofibers. Opto-Electron Adv 3, 190022 (2020). [29] Tong LM. Micro/nanofibre optical sensors: challenges and prospects. Sensors 18, 903 (2018). doi: 10.3390/s18030903 [30] Chen JH, Li DR, Xu F. Optical microfiber sensors: sensing mechanisms, and recent advances. J Light Technol 37, 2577–2589 (2019). doi: 10.1109/JLT.2018.2877434 [31] Guan BO, Huang YY. Interface sensitized optical microfiber biosensors. J Light Technol 37, 2616–2622 (2019). doi: 10.1109/JLT.2018.2889324 [32] Li YP, Xu ZL, Tan SJ et al. Recent advances in microfiber sensors for highly sensitive biochemical detection. J Phys D Appl Phys 52, 493002 (2019). doi: 10.1088/1361-6463/ab3d4e [33] Xu YX, Fang W, Tong LM. Real-time control of micro/nanofiber waist diameter with ultrahigh accuracy and precision. Opt Express 25, 10434–10440 (2017). doi: 10.1364/OE.25.010434 [34] Kang Y, Gong J, Xu YX et al. Ultrahigh-precision diameter control of nanofiber using direct mode cutoff feedback. IEEE Photonics Technol Lett 32, 219–222 (2020). doi: 10.1109/LPT.2020.2966804 [35] Yao N, Linghu SY, Xu YX et al. Ultra-long subwavelength micro/nanofibers with low loss. IEEE Photonics Technol Lett 32, 1069–1072 (2020). doi: 10.1109/LPT.2020.3011719 [36] Xiao JL, Zhou T, Yao N et al. Optical fibre taper-enabled waveguide photoactuators. Nat Commun 13, 363 (2022). doi: 10.1038/s41467-022-28021-4 [37] Pilz da Cunha M, Debije MG, Schenning APHJ. Bioinspired light-driven soft robots based on liquid crystal polymers. Chem Soc Rev 49, 6568–6578 (2020). doi: 10.1039/D0CS00363H [38] El-Atab N, Mishra RB, Al-Modaf F et al. Soft actuators for soft robotic applications: a review. Adv Intell Syst 2, 2000128 (2020). doi: 10.1002/aisy.202000128 [39] Li JJ, Zhou X, Liu ZF. Recent advances in photoactuators and their applications in intelligent bionic movements. Adv Opt Mater 8, 2000886 (2020). doi: 10.1002/adom.202000886 [40] Kuenstler AS, Kim H, Hayward RC. Liquid crystal elastomer waveguide actuators. Adv Mater 31, 1901216 (2019). doi: 10.1002/adma.201901216 [41] Zmyślony M, Dradrach K, Haberko J et al. Optical pliers: micrometer-scale, light-driven tools grown on optical fibers. Adv Mater 32, 2002779 (2020). doi: 10.1002/adma.202002779 [42] He YC, Liang HH, Chen MH et al. Optical fiber waveguiding soft photoactuators exhibiting giant reversible shape change. Adv Opt Mater 9, 2101132 (2021). doi: 10.1002/adom.202101132 [43] Guo JJ, Yang CX, Dai QH et al. Soft and stretchable polymeric optical waveguide-based sensors for wearable and biomedical applications. Sensors 19, 3771 (2019). doi: 10.3390/s19173771 [44] Wang XC, Li ZL, Su L. Soft optical waveguides for biomedical applications, wearable devices, and soft robotics: a review. Adv Intell Syst 6, 2300482 (2024). doi: 10.1002/aisy.202300482 [45] Chen MX, Wang Z, Li KW et al. Elastic and stretchable functional fibers: a review of materials, fabrication methods, and applications. Adv Fiber Mater 3, 1–13 (2021). doi: 10.1007/s42765-020-00057-5 [46] Liu HH, Hu DJJ, Sun QZ et al. Specialty optical fibers for advanced sensing applications. Opto-Electron Sci 2, 220025 (2023). doi: 10.29026/oes.2023.220025 [47] Yang MJ, Yuan ZK, Liu J et al. Photoresponsive actuators built from carbon-based soft materials. Adv Opt Mater 7, 1900069 (2019). doi: 10.1002/adom.201900069 [48] Costil R, Holzheimer M, Crespi S et al. Directing coupled motion with light: a key step toward machine-like function. Chem Rev 121, 13213–13237 (2021). doi: 10.1021/acs.chemrev.1c00340 [49] Tong LM, Gattass RR, Ashcom JB et al. Subwavelength-diameter silica wires for low-loss optical wave guiding. Nature 426, 816–819 (2003). doi: 10.1038/nature02193 [50] Wu XQ, Tong LM. Optical microfibers and nanofibers. Nanophotonics 2, 407–428 (2013). doi: 10.1515/nanoph-2013-0033 [51] Zhang L, Gu FX, Lou JY et al. Fast detection of humidity with a subwavelength-diameter fiber taper coated with gelatin film. Opt Express 16, 13349–13353 (2008). doi: 10.1364/OE.16.013349 [52] Fang HB, Xie Y, Yuan ZP et al. Parallel fabrication of silica optical microfibers and nanofibers. Light Adv Manuf 5, 20 (2024). [53] Liu N, Yao N, Wang SP et al. An optical nanofibre-enabled on-chip single-nanoparticle sensor. Lab Chip 23, 4901–4908 (2023). doi: 10.1039/D3LC00499F [54] Pan J, Zhang Z, Jiang CP et al. A multifunctional skin-like wearable optical sensor based on an optical micro-/nanofibre. Nanoscale 12, 17538–17544 (2020). doi: 10.1039/D0NR03446K [55] Lou JY, Tong LM, Ye ZZ. Modeling of silica nanowires for optical sensing. Opt Express 13, 2135–2140 (2005). doi: 10.1364/OPEX.13.002135 [56] Luo W, Chen Y, Xu F. Recent progress in microfiber-optic sensors. Photonic Sens 11, 45–68 (2021). doi: 10.1007/s13320-021-0614-9 [57] Sun LP, Huang YY, Guan BO. Microfiber interferometric biosensors. Laser Optoelectron Prog 58, 1306004 (2021). doi: 10.3788/LOP202158.1306004 [58] Tong LM. Recent progress in optical micro/nanofiber technology. Acta Opt Sin 42, 1706001 (2022). doi: 10.3788/AOS202242.1706001 [59] Sumetsky M, Dulashko Y, Fini JM et al. Optical microfiber loop resonator. Appl Phys Lett 86, 161108 (2005). doi: 10.1063/1.1906317 [60] Jiang XS, Song QH, Xu L et al. Microfiber knot dye laser based on the evanescent-wave-coupled gain. Appl Phys Lett 90, 233501 (2007). doi: 10.1063/1.2746935 [61] White IM, Oveys H, Fan XD. Liquid-core optical ring-resonator sensors. Opt Lett 31, 1319–1321 (2006). doi: 10.1364/OL.31.001319 [62] Wang SS, Hu ZF, Li YH et al. All-fiber Fabry-Perot resonators based on microfiber Sagnac loop mirrors. Opt Lett 34, 253–255 (2009). doi: 10.1364/OL.34.000253 [63] Kou JL, Feng J, Wang QJ et al. Microfiber-probe-based ultrasmall interferometric sensor. Opt Lett 35, 2308–2310 (2010). doi: 10.1364/OL.35.002308 [64] Jiang BQ, Hou YG, Wu JX et al. In-fiber photoelectric device based on graphene-coated tilted fiber grating. Opto-Electron Sci 2, 230012 (2023). doi: 10.29026/oes.2023.230012 [65] Zhang Y, Lin B, Tjin SC et al. Refractive index sensing based on higher-order mode reflection of a microfiber Bragg grating. Opt Express 18, 26345–26350 (2010). doi: 10.1364/OE.18.026345 [66] Liu YX, Meng C, Zhang AP et al. Compact microfiber Bragg gratings with high-index contrast. Opt Lett 36, 3115–3117 (2011). doi: 10.1364/OL.36.003115 [67] Sun LP, Li J, Jin L et al. Structural microfiber long-period gratings. Opt Express 20, 18079–18084 (2012). doi: 10.1364/OE.20.018079 [68] Li BL, Chen JH, Xu F et al. Periodic micro-structures in optical microfibers induced by Plateau-Rayleigh instability and its applications. Opt Express 25, 4326–4334 (2017). doi: 10.1364/OE.25.004326 [69] Xuan HF, Jin W, Zhang M. CO2 laser induced long period gratings in optical microfibers. Opt Express 17, 21882–21890 (2009). doi: 10.1364/OE.17.021882 [70] Li YH, Tong LM. Mach-Zehnder interferometers assembled with optical microfibers or nanofibers. Opt Lett 33, 303–305 (2008). doi: 10.1364/OL.33.000303 [71] Zheng YZ, Dong XY, Chan CC et al. Optical fiber magnetic field sensor based on magnetic fluid and microfiber mode interferometer. Opt Commun 336, 5–8 (2015). doi: 10.1016/j.optcom.2014.09.026 [72] Luo YF, Abidian MR, Ahn JH et al. Technology roadmap for flexible sensors. ACS Nano 17, 5211–5295 (2023). doi: 10.1021/acsnano.2c12606 [73] Li W, Hu ZF, Li XY et al. High-sensitivity microfiber strain and force sensors. Opt Commun 314, 28–30 (2014). doi: 10.1016/j.optcom.2013.09.072 [74] Yu XC, Zhi YY, Tang SJ et al. Optically sizing single atmospheric particulates with a 10-nm resolution using a strong evanescent field. Light Sci Appl 7, 18003 (2018). doi: 10.1038/lsa.2018.3 [75] Mei HY, Pan J, Zhang Z et al. Coiled optical nanofiber for optofluidic absorbance detection. ACS Sens 4, 2267–2271 (2019). doi: 10.1021/acssensors.9b00913 [76] Cai DW, Tong T, Zhang Z et al. Functional film coated optical micro/nanofibers for high-performance gas sensing. IEEE Sens J 19, 9229–9234 (2019). doi: 10.1109/JSEN.2019.2924596 [77] Jiang XS, Tong LM, Vienne G et al. Demonstration of optical microfiber knot resonators. Appl Phys Lett 88, 223501 (2006). doi: 10.1063/1.2207986 [78] Sumetsky M, Dulashko Y, Fini JM et al. The microfiber loop resonator: theory, experiment, and application. J Light Technol 24, 242–250 (2006). doi: 10.1109/JLT.2005.861127 [79] Vienne G, Li YH, Tong LM. Effect of host polymer on microfiber resonator. IEEE Photonics Technol Lett 19, 1386–1388 (2007). doi: 10.1109/LPT.2007.903340 [80] Xu F, Brambilla G. Embedding optical microfiber coil resonators in Teflon. Opt Lett 32, 2164–2166 (2007). doi: 10.1364/OL.32.002164 [81] Lu JS, Ginis V, Qiu CW et al. Polarization-dependent forces and torques at resonance in a microfiber-microcavity system. Phys Rev Lett 130, 183601 (2023). doi: 10.1103/PhysRevLett.130.183601 [82] Zhang YN, Gao J, Xia F et al. Microfiber knot resonators: structure, spectral properties, and sensing applications. Laser Photonics Rev 18, 2300765 (2024). doi: 10.1002/lpor.202300765 [83] Xu ZL, Luo YY, Sun QZ et al. Light velocity control in monolithic microfiber bridged ring resonator. Optica 4, 945–950 (2017). doi: 10.1364/OPTICA.4.000945 [84] Chen Y, Yan SC, Zheng X et al. A miniature reflective micro-force sensor based on a microfiber coupler. Opt Express 22, 2443–2450 (2014). doi: 10.1364/OE.22.002443 [85] Luo HP, Sun QZ, Xu ZL et al. Microfiber-based inline mach–zehnder interferometer for dual-parameter measurement. IEEE Photonics J 7, 7100908 (2015). [86] Wang PF, Ding M, Bo L et al. Fiber-tip high-temperature sensor based on multimode interference. Opt Lett 38, 4617–4620 (2013). doi: 10.1364/OL.38.004617 [87] Li YP, Tan SJ, Yang LY et al. Optical microfiber neuron for finger motion perception. Adv Fiber Mater 4, 226–234 (2022). doi: 10.1007/s42765-021-00096-6 [88] Li KW, Zhang T, Liu GG et al. Ultrasensitive optical microfiber coupler based sensors operating near the turning point of effective group index difference. Appl Phys Lett 109, 101101 (2016). doi: 10.1063/1.4961981 [89] Yan SC, Liu ZY, Li C et al. "Hot-wire" microfluidic flowmeter based on a microfiber coupler. Opt Lett 41, 5680–5683 (2016). doi: 10.1364/OL.41.005680 [90] Zhang Z, Yao N, Pan J et al. A new route for fabricating polymer optical microcavities. Nanoscale 11, 5203–5208 (2019). doi: 10.1039/C8NR10007A [91] Wang X, Zhou HY, Chen MH et al. Highly sensitive strain sensor based on microfiber coupler for wearable photonics healthcare. Adv Intell Syst 5, 2200344 (2023). doi: 10.1002/aisy.202200344 [92] Song XD, Wang Q, Liu QL et al. Twisted optical micro/nanofibers enabled detection of subtle temperature variation. ACS Appl Mater Interfaces 15, 47177–47183 (2023). doi: 10.1021/acsami.3c07831 [93] Yu W, Yao N, Pan J et al. Highly sensitive and fast response strain sensor based on evanescently coupled micro/nanofibers. Opto-Electron Adv 5, 210101 (2022). doi: 10.29026/oea.2022.210101 [94] Ran Y, Tan YN, Sun LP et al. 193 nm excimer laser inscribed Bragg gratings in microfibers for refractive index sensing. Opt Express 19, 18577–18583 (2011). doi: 10.1364/OE.19.018577 [95] Kou JL, Ding M, Feng J et al. Microfiber-based Bragg gratings for sensing applications: a review. Sensors 12, 8861–8876 (2012). doi: 10.3390/s120708861 [96] Yue X, Lu RY, Yang QC et al. Flexible wearable optical sensor based on optical microfiber bragg grating. J Light Technol 41, 1858–1864 (2023). doi: 10.1109/JLT.2022.3227186 [97] Meng KY, Xiao X, Wei WX et al. Wearable pressure sensors for pulse wave monitoring. Adv Mater 34, 2109357 (2022). doi: 10.1002/adma.202109357 [98] Wang S, Xiao JL, Liu HT et al. Silk nanofibrous iontronic sensors for accurate blood pressure monitoring. Chem Eng J 453, 139815 (2023). doi: 10.1016/j.cej.2022.139815 [99] Lin QP, Huang J, Yang JL et al. Highly sensitive flexible iontronic pressure sensor for fingertip pulse monitoring. Adv Healthc Mater 9, 2001023 (2020). doi: 10.1002/adhm.202001023 [100] Li LY, Liu YF, Song CY et al. Wearable alignment-free microfiber-based sensor chip for precise vital signs monitoring and cardiovascular assessment. Adv Fiber Mater 4, 475–486 (2022). doi: 10.1007/s42765-021-00121-8 [101] Park J, Kim M, Lee Y et al. Fingertip skin-inspired microstructured ferroelectric skins discriminate static/dynamic pressure and temperature stimuli. Sci Adv 1, e1500661 (2015). doi: 10.1126/sciadv.1500661 [102] Yao N, Wang XY, Ma SQ et al. Single optical microfiber enabled tactile sensor for simultaneous temperature and pressure measurement. Photonics Res 10, 2040–2046 (2022). doi: 10.1364/PRJ.461182 [103] Zhu HT, Zhan LW, Dai Q et al. Self-assembled wavy optical microfiber for stretchable wearable sensor. Adv Opt Mater 9, 2002206 (2021). doi: 10.1002/adom.202002206 [104] Zhu HT, Luo JX, Dai Q et al. Spatiotemporal hemodynamic monitoring via configurable skin-like microfiber Bragg grating group. Opto-Electron Adv 6, 230018 (2023). doi: 10.29026/oea.2023.230018 [105] Zhang Z, Kang YR, Yao N et al. A multifunctional airflow sensor enabled by optical micro/nanofiber. Adv Fiber Mater 3, 359–367 (2021). doi: 10.1007/s42765-021-00097-5 [106] Mishra P, Kumar H, Sahu S et al. Flexible and wearable optical system based on u-shaped cascaded microfiber interferometer. Adv Mater Technol 8, 2200661 (2023). doi: 10.1002/admt.202200661 [107] Yang LY, Li YP, Fang F et al. Highly sensitive and miniature microfiber-based ultrasound sensor for photoacoustic tomography. Opto-Electron Adv 5, 200076 (2022). doi: 10.29026/oea.2022.200076 [108] Ma J, Zhao J, Chen HW et al. Transparent microfiber Fabry-Perot ultrasound sensor with needle-shaped focus for multiscale photoacoustic imaging. Photoacoustics 30, 100482 (2023). doi: 10.1016/j.pacs.2023.100482 [109] Shum PP, Keiser G, Humbert G et al. Highly sensitive microfiber ultrasound sensor for photoacoustic imaging. Opto-Electron Adv 6, 230065 (2023). doi: 10.29026/oea.2023.230065 [110] Ko SH, Rogers J. Functional materials and devices for XR (VR/AR/MR) applications. Adv Funct Mater 31, 2106546 (2021). doi: 10.1002/adfm.202106546 [111] Kim H, Kwon YT, Lim HR et al. Recent advances in wearable sensors and integrated functional devices for virtual and augmented reality applications. Adv Funct Mater 31, 2170289 (2021). doi: 10.1002/adfm.202170289 [112] Zhu ML, Sun ZD, Lee C. Soft modular glove with multimodal sensing and augmented haptic feedback enabled by materials' multifunctionalities. ACS Nano 16, 14097–14110 (2022). doi: 10.1021/acsnano.2c04043 [113] Li Y, Yang LN, He ZM et al. Low-cost data glove based on deep-learning-enhanced flexible multiwalled carbon nanotube sensors for real-time gesture recognition. Adv Intell Syst 4, 2200128 (2022). doi: 10.1002/aisy.202200128 [114] Zhao YL, Liu JL, Lian C et al. A single smart ring for monitoring 20 kinds of multi-intensity daily activities-from kitchen work to fierce exercises. Adv Intell Syst 4, 2270058 (2022). doi: 10.1002/aisy.202270058 [115] Tan PC, Han X, Zou Y et al. Self-powered gesture recognition wristband enabled by machine learning for full keyboard and multicommand input. Adv Mater 34, 2200793 (2022). doi: 10.1002/adma.202200793 [116] Fang H, Wang L, Fu ZZ et al. Anatomically designed triboelectric wristbands with adaptive accelerated learning for human-machine interfaces. Adv Sci 10, 2205960 (2023). doi: 10.1002/advs.202205960 [117] Luo YY, Li YZ, Sharma P et al. Learning human-environment interactions using conformal tactile textiles. Nat Electron 4, 193–201 (2021). doi: 10.1038/s41928-021-00558-0 [118] Araromi OA, Graule MA, Dorsey KL et al. Ultra-sensitive and resilient compliant strain gauges for soft machines. Nature 587, 219–224 (2020). doi: 10.1038/s41586-020-2892-6 [119] Yang J, Zhou J, Tao GM et al. Wearable 3.0: from smart clothing to wearable affective robot. IEEE Netw 33, 8–14 (2019). [120] Wang SP, Wang XY, Wang S et al. Optical-nanofiber-enabled gesture-recognition wristband for human-machine interaction with the assistance of machine learning. Adv Intell Syst 5, 2200412 (2023). doi: 10.1002/aisy.202200412 [121] Weng W, Yang JJ, Zhang Y et al. A route toward smart system integration: from fiber design to device construction. Adv Mater 32, 1902301 (2020). doi: 10.1002/adma.201902301 [122] Ma SQ, Wang XY, Li P et al. Optical micro/nano fibers enabled smart textiles for human-machine interface. Adv Fiber Mater 4, 1108–1117 (2022). doi: 10.1007/s42765-022-00163-6 [123] Li T, Li LH, Sun HW et al. Porous ionic membrane based flexible humidity sensor and its multifunctional applications. Adv Sci 4, 1600404 (2017). doi: 10.1002/advs.201600404 [124] Zhou KK, Xu WJH, Yu YF et al. Tunable and nacre-mimetic multifunctional electronic skins for highly stretchable contact-noncontact sensing. Small 17, 2100542 (2021). doi: 10.1002/smll.202100542 [125] Liu HT, Song XD, Wang XY et al. Optical microfibers for sensing proximity and contact in human-machine interfaces. ACS Appl Mater Interfaces 14, 14447–14454 (2022). doi: 10.1021/acsami.1c23716 [126] Li GZ, Liu SQ, Wang LQ et al. Skin-inspired quadruple tactile sensors integrated on a robot hand enable object recognition. Sci Robot 5, eabc8134 (2020). doi: 10.1126/scirobotics.abc8134 [127] Kim T, Kim J, You I et al. Dynamic tactility by position-encoded spike spectrum. Sci Robot 7, eabl5761 (2022). doi: 10.1126/scirobotics.abl5761 [128] Jiang CP, Zhang Z, Pan J et al. Finger-skin-inspired flexible optical sensor for force sensing and slip detection in robotic grasping. Adv Mater Technol 6, 2100285 (2021). doi: 10.1002/admt.202100285 [129] Tang Y, Yu LT, Pan J et al. Optical nanofiber skins for multifunctional humanoid tactility. Adv Intell Syst 5, 2200203 (2023). doi: 10.1002/aisy.202200203 [130] Tang Y, Liu HT, Pan J et al. Optical micro/nanofiber-enabled compact tactile sensor for hardness discrimination. ACS Appl Mater Interfaces 13, 4560–4566 (2021). doi: 10.1021/acsami.0c20392 [131] Han B, Zhang YL, Chen QD et al. Carbon-based photothermal actuators. Adv Funct Mater 28, 1802235 (2018). doi: 10.1002/adfm.201802235 [132] Jiao DJ, Zhu QL, Li CY et al. Programmable morphing hydrogels for soft actuators and robots: from structure designs to active functions. Acc Chem Res 55, 1533–1545 (2022). doi: 10.1021/acs.accounts.2c00046 [133] Liu C, Ji SB, Xu HP. Rapidly reprogrammable actuation of liquid crystal elastomers. Matter 5, 2409–2413 (2022). doi: 10.1016/j.matt.2022.05.009 [134] Peng WJ, Zhang GG, Liu J et al. Light-coded digital crystallinity patterns toward bioinspired 4D transformation of shape-memory polymers. Adv Funct Mater 30, 2000522 (2020). doi: 10.1002/adfm.202000522 [135] Zhou Y, Hauser AW, Bende NP et al. Waveguiding microactuators based on a photothermally responsive nanocomposite hydrogel. Adv Funct Mater 26, 5447–5452 (2016). doi: 10.1002/adfm.201601569 -

Access History

Article Metrics

-

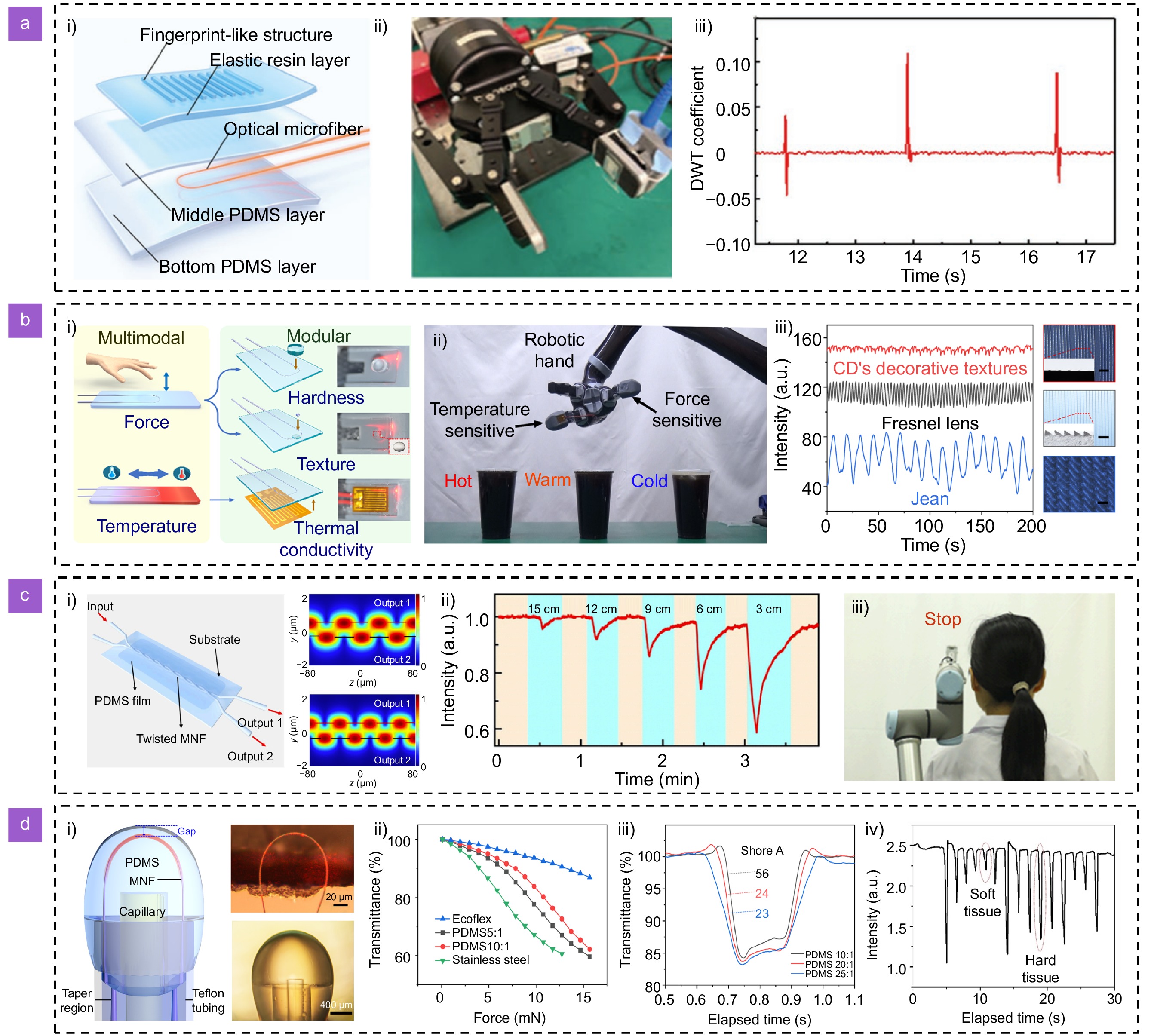

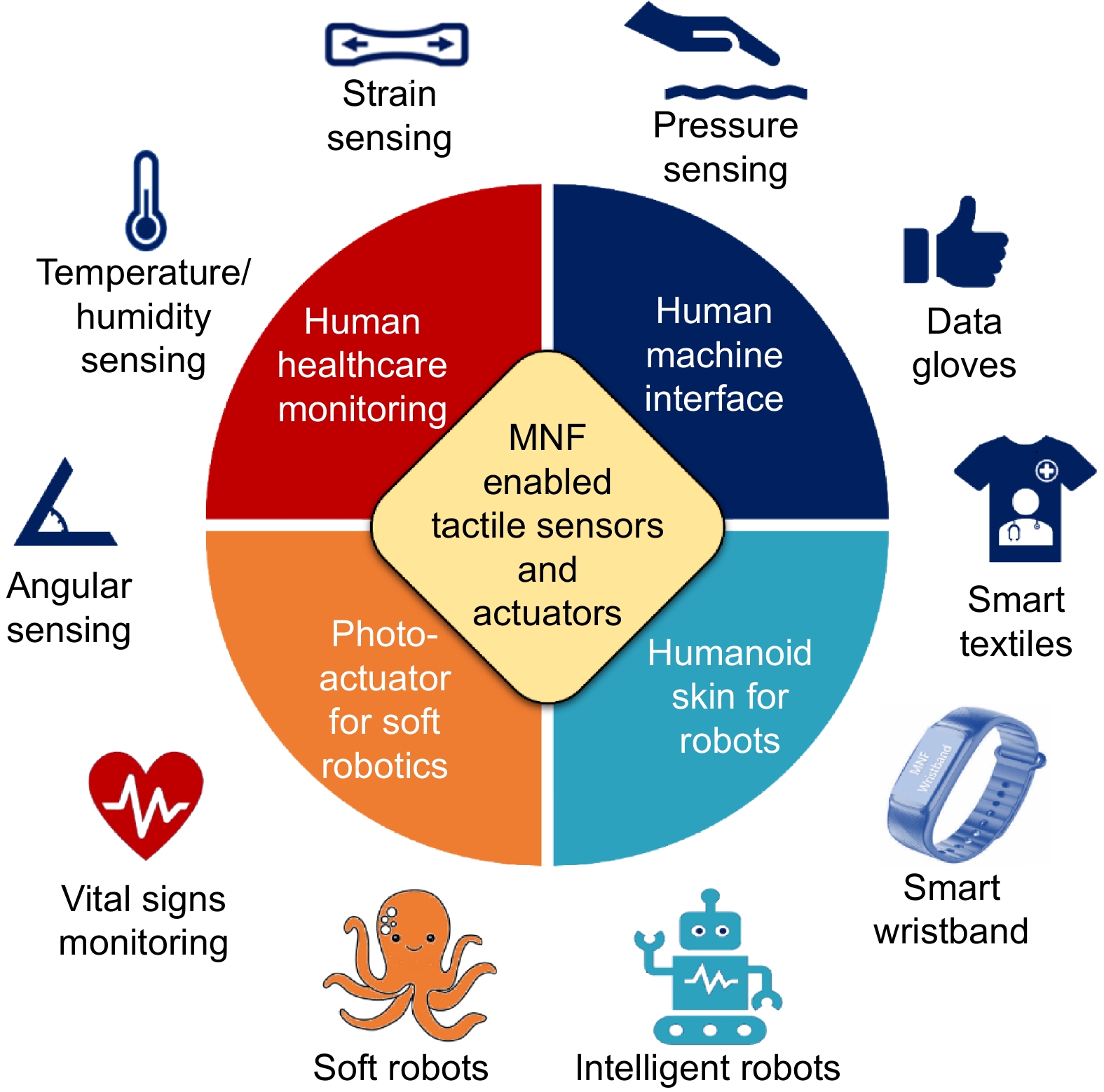

Figure 1.

Characteristic properties and diverse functions and applications of recently developed tactile sensors and soft actuators.

-

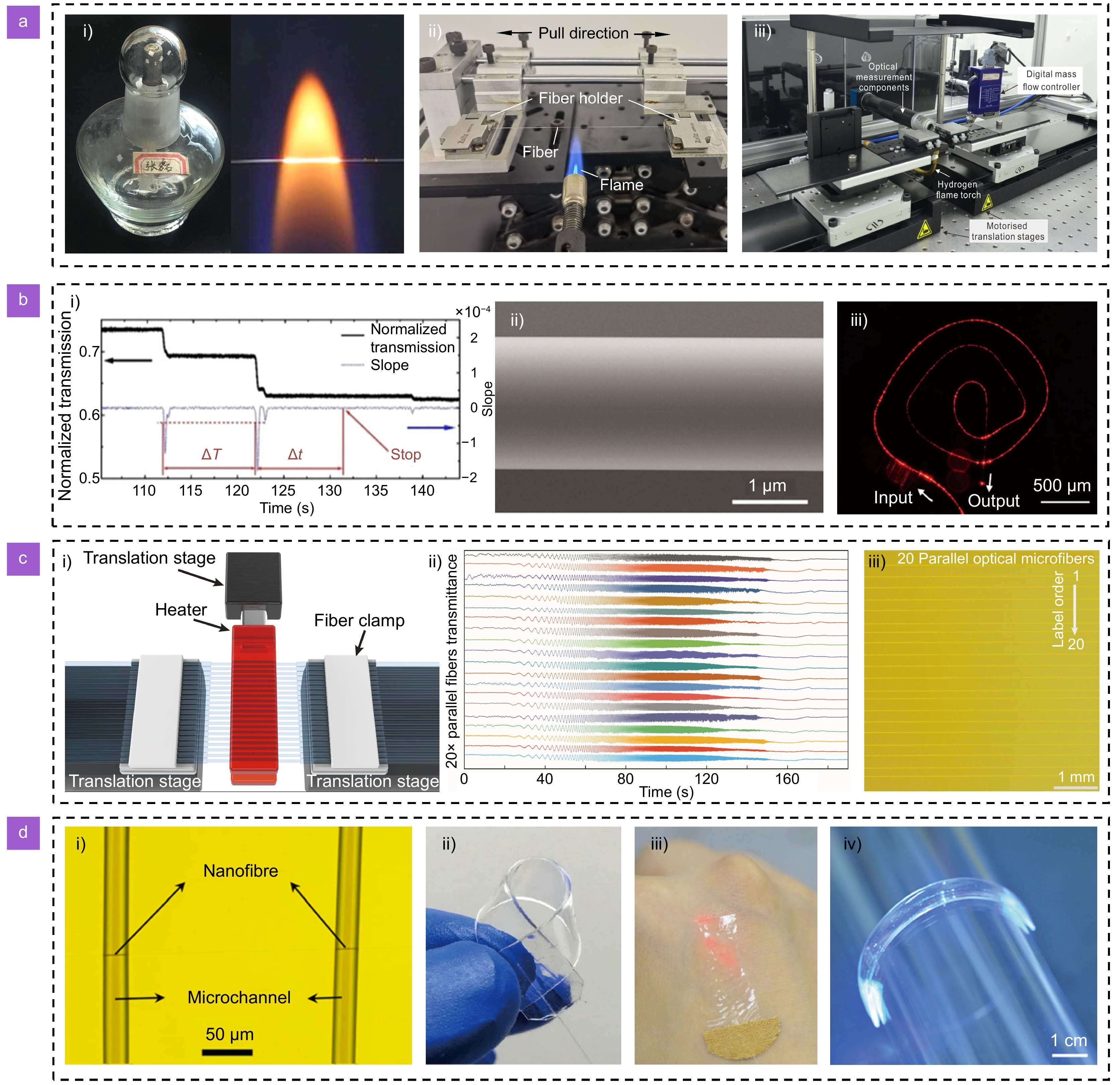

Figure 2.

Fabrication and packaging the optical micro/nanofibers. (a) Evolution of flame-heated taper drawing setup. i) An alcohol burner and its flame; ii) A stage assisted taper drawing setup; iii) An automatic taper drawing setup. Figure reproduced with permission from ref.28, under a Creative Commons Attribution 4.0 International License. (b) Fabrication of MNF with controlled diameter. i) Control of MNF diameter by real time measuring the time interval between two drops; ii) SEM image of an as-fabricated MNF with uniform diameter; iii) Spiral MNF guiding 633-nm-wavelength laser. Figures reproduced with permission from: i-ii) ref.33, © 2017 Optical Society of America; iii) ref.28, under a Creative Commons Attribution 4.0 International License. (c) Fabrication of MNF array with an electric heater. i) Schematic of a taper drawing setup for fabricating MNF array; ii) Recorded the multimode-induced oscillation for 20 MNFs during the taper drawing process; iii) 20 MNFs in parallel. Figures reproduced with permission from ref.52, under a Creative Commons Attribution 4.0 International License. (d) Packaging the MNFs with PDMS. i) Micrograph of a microfluidic chip embedded MNF; ii) Bent PDMS packaged MNF in free space; iii-iv) PDMS packaged MNF attached on human skin (iii) and curved surface (iv), respectively. Figures reproduced with permission from: i) ref.53, the Royal Society of Chemistry; ii-iii) ref.28, under a Creative Commons Attribution 4.0 International License; iv) ref.54, the Royal Society of Chemistry.

-

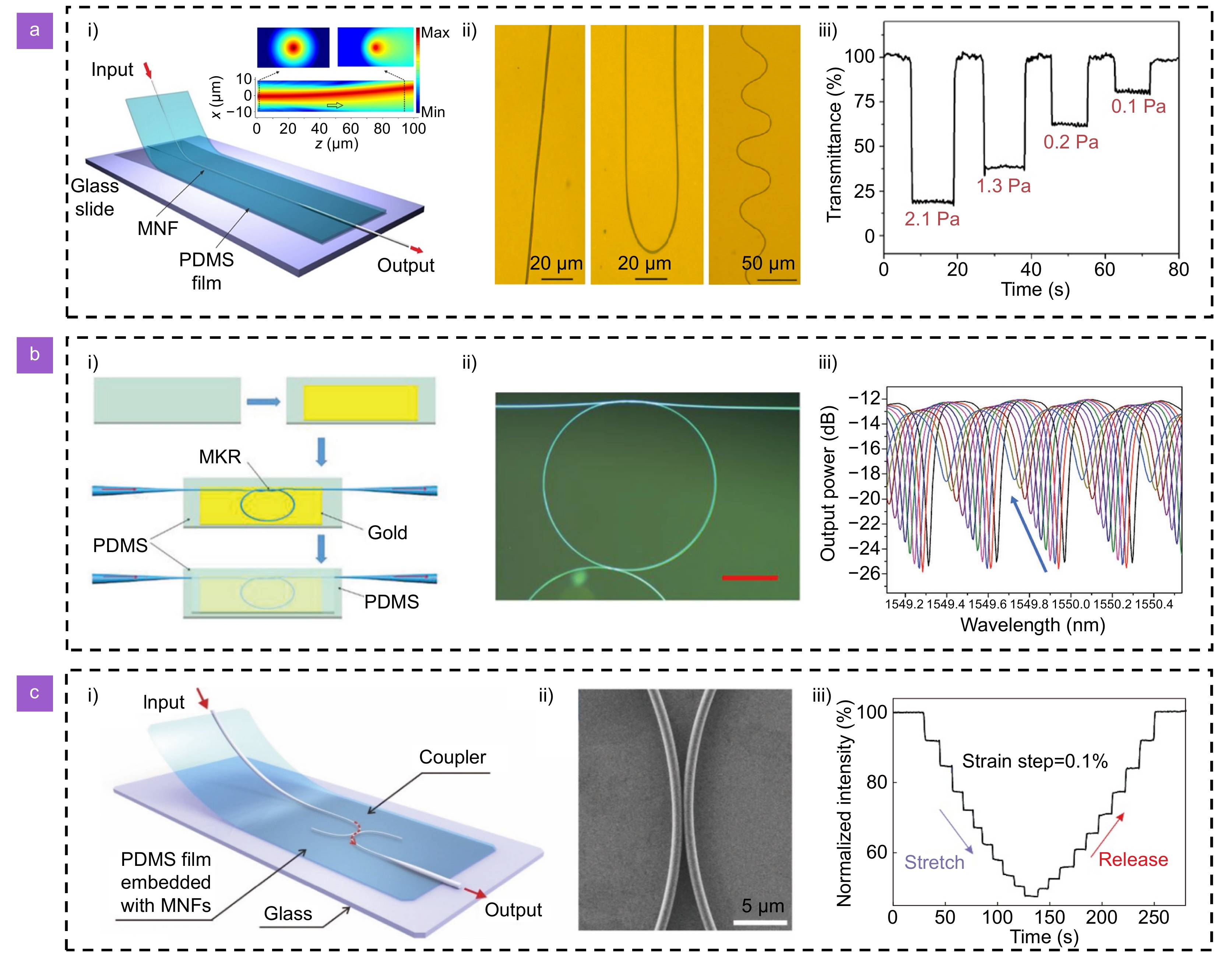

Figure 3.

Sensing mechanisms of MNF enabled tactile sensors. (a) Biconical MNF enabled tactile sensor. i) Schematic of biconical MNF embedded in a thin layer of PDMS; Inset: Optical field intensity distributions of 900-nm-wavelength light guiding along a 1-µm-diameter glass MNF embedded in a 5°-bent MNF sensor; ii) Optical images of MNFs with different shapes; iii) Optical response of an MNF tactile sensor to weak pressure. Figures reproduced with permission from ref.28, under a Creative Commons Attribution 4.0 International License. (b) MNF ring resonator enabled tactile sensor. i) Schematic of the fabrication process of the MNF ring resonator. ii) Microscope image of the MNF ring resonator on the gold film. Scale bar: 200 µm; iii) Resonant wavelength shift of the MNF sensor. Figures reproduced with permission from ref.27, © 2018 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. (c) MNF coupler enabled tactile sensor. i) Schematic of MNF coupler sensor; ii) SEM image of an MNF coupler; iii) Optical response of the coupler sensor in a stretch and release cycle. Figure reproduced with permission from ref.93, under a Creative Commons Attribution 4.0 International License.

-

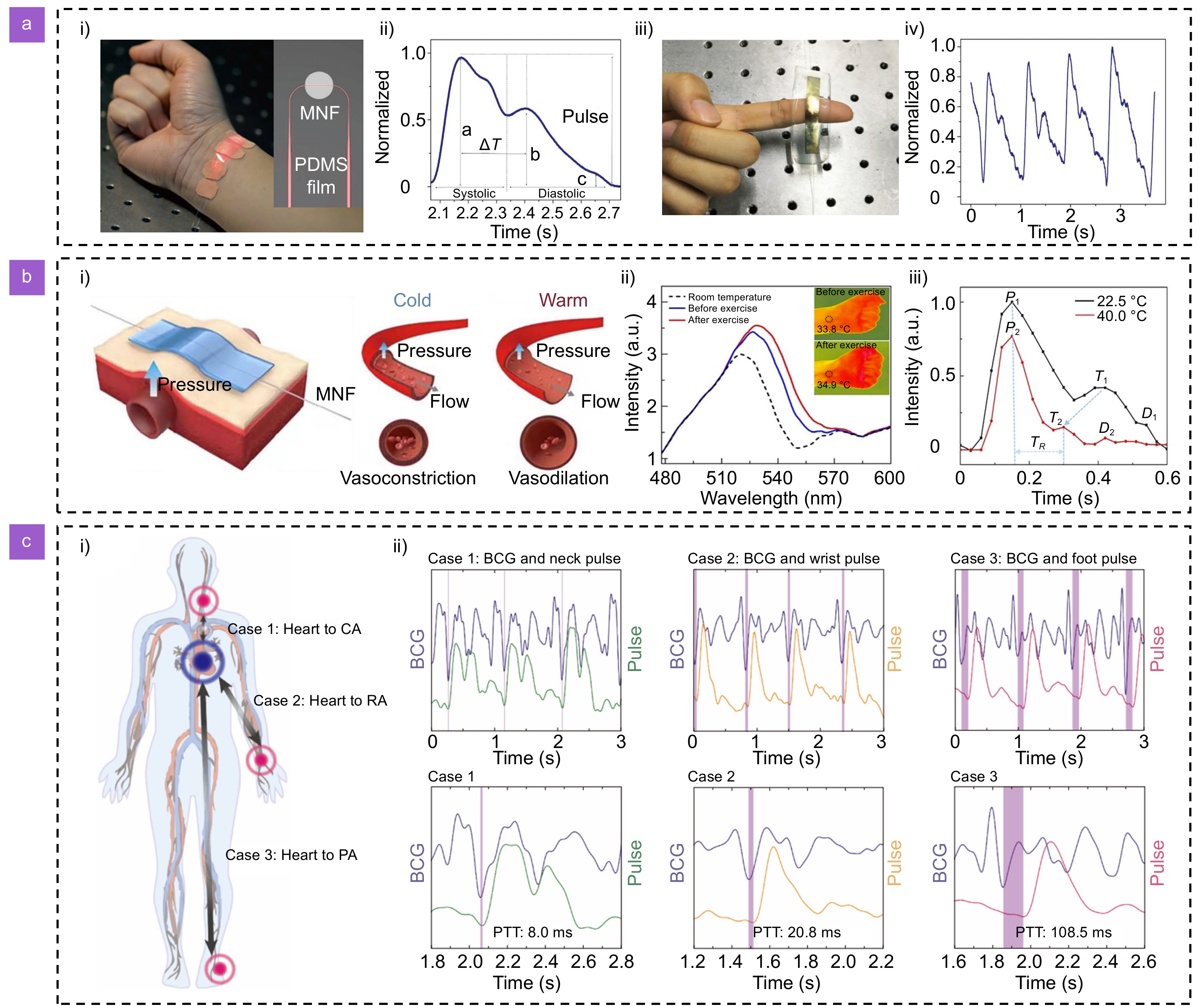

Figure 4.

MNF tactile sensors for pulse monitoring. (a) Typical wrist pulse (i) and fingertip pulse (iii) sensors and corresponding waveforms (ii and iv). Figures reproduced with permission from: i) ref.28, under a Creative Commons Attribution 4.0 International License; ii-iv) ref.27, © 2018 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. (b) Single MNF enabled wrist pulse sensor for simultaneous temperature and pulse measurement. i) Schematic of the pulse sensor; ii) Typical spectral response of the pulse sensor before and after exercise; iii) Comparison of the artery pulse pressure waveform variation with wrist temperature of 22.5 °C and 40.0 °C. Figures reproduced with permission from ref.102, © 2022 Chinese Laser Press. (c) Spatiotemporal hemodynamic monitoring via configurable skin-like microfiber Bragg grating group. i) Schematic diagram of the measurement positions for the three cases; ii) The details of the BCG signal and pulse wave within one cardiac cycle. Case 1: simultaneous measurement of BCG and pulse wave at the carotid artery (CA). Case 2: simultaneous measurement of BCG and pulse wave at the radial artery (RA). Case 3: simultaneous measurement of BCG and pulse wave at the pedal artery (PA). Figures reproduced with permission from: ref.104, under a Creative Commons Attribution 4.0 International License.

-

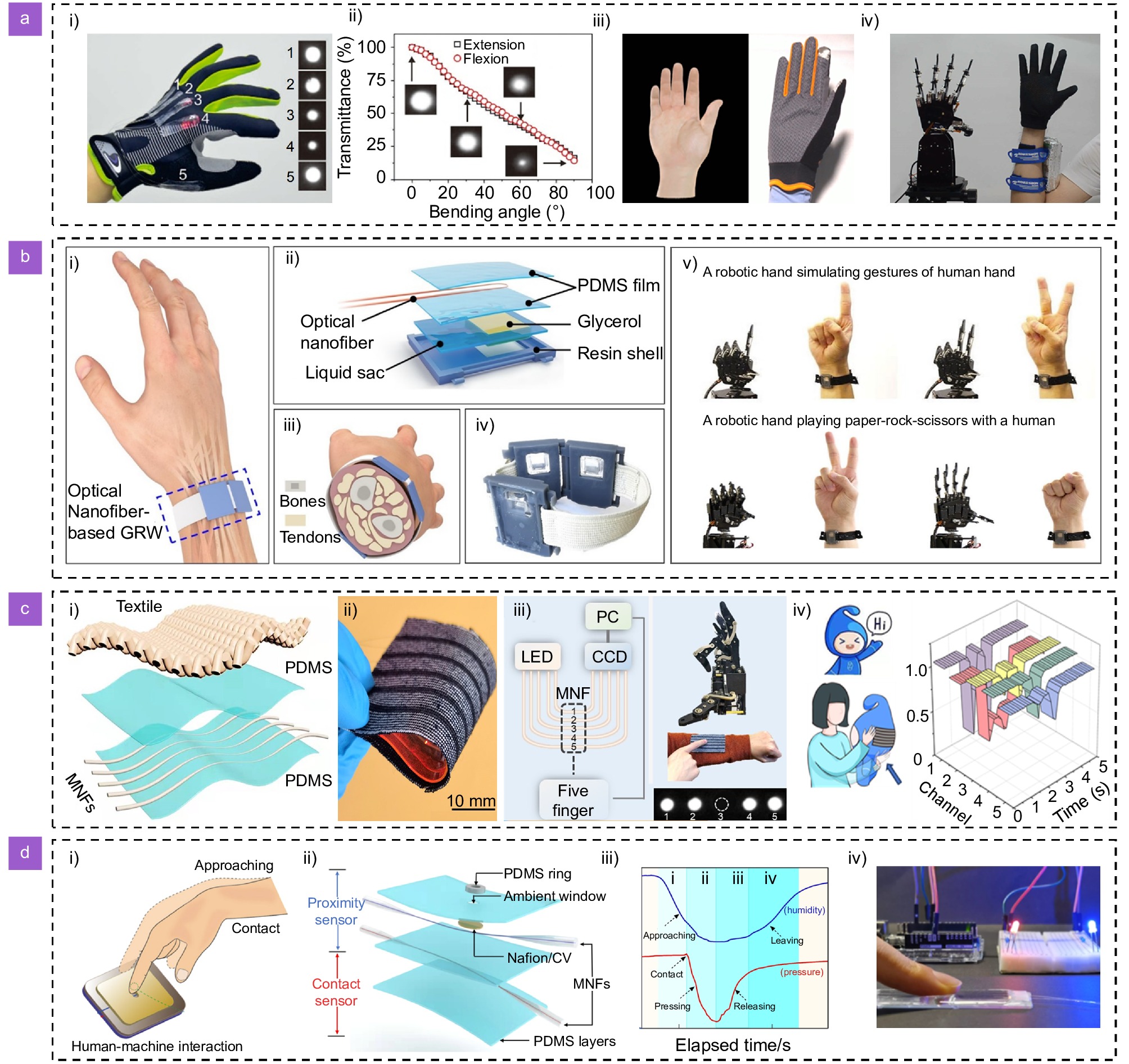

Figure 5.

MNF tactile sensors for human machine interaction. (a) MNF bending sensor enabled data gloves. i) Image of an MNF glove with five bending sensors; ii) Bending-angle-dependent output of a typical MNF bending sensor; iii) Image of a virtual hand controlled by an MNF data glove; iv) Image of a robotic hand controlled by an MNF data glove. Figures reproduced with permission from ref.28, under a Creative Commons Attribution 4.0 International License. (b) MNF pressure sensor enabled wristband. i) Schematic of the MNF enabled wristband; ii) Schematic of the MNF pressure sensor; iii) Cross-section of a wrist with a three-sensor wristband, indicating the position of the sensors and tendons; iv) Photograph of a three-sensor wristband; v) Application of the wristband for controlling a robotic hand based on hand gesture recognition. Figures reproduced with permission from ref.120, under a Creative Commons Attribution License. (c) MNF pressure sensor enabled smart textiles. i) Schematic of optical MNF enabled smart textiles. ii) Optical image of the as-fabricated smart textiles. iii) Logic control of a robotic hand via the smart textile. iv) Machine learning enabled emotional human machine interface. Figures reproduced with permission from ref.122, © 2022 Donghua University, Shanghai, China. (d) MNF humidity and pressure sensor enabled contact and proximity sensing. i) Schematic diagram of contact and proximity interaction; ii) Schematic of the contact and proximity sensor; iii) Responses of the sensor under finger approaching and contacting; iv) Photograph of the contact and proximity switch system for controlling the on/off of the LEDs. Figures reproduced with permission from ref.125, © 2022 American Chemical Society.

-

Figure 6.

MNF tactile sensors for robots. (a) Finger-skin-inspired MNF sensor for force sensing and slip detection. i) Schematic of the finger-skin-inspired MNF sensor; ii) Photograph of a robotic gripper equipped with an MNF sensor; iii) Discrete wavelet transform of the response curves with three peaks. Each peak indicates a slip of the object grasped by the robotic hand. Figures reproduced with permission from ref.128, © 2021 Wiley-VCH GmbH. (b) Multimodal and modular MNF sensors for multifunctional humanoid tactility. i) Schematic of the multimodal and modular MNF sensors; ii) A robotic hand equipped with the MNF sensor is ready to recognize and pick up a cup of warm coffee. iii) The responses of the MNF sensor for the texture recognition of CD, Fresnel lens and jean. Figures reproduced with permission from ref.129, under a Creative Commons Attribution License. (c) Twisted MNFs enabled ultrasensitive temperature sensor. i) Schematic of the twisted MNFs sensor; ii) Response of hand proximity with different distances; iii) The robot with temperature feedback can effectively avoid undesired collisions. Figures reproduced with permission from ref.92, © 2023 American Chemical Society. (d) MNF-enabled compact tactile sensor for hardness discrimination. i) Schematic and photograph of the U-shaped MNF-enabled compact tactile sensor; ii) Optical response of the sensor to objects with different hardness; iii) Intensity curves corresponding to objects with different hardness; iv) Intensity curves corresponding to pork liver and an adductor muscle. Figures reproduced with permission from ref.130, © 2021 American Chemical Society.

-

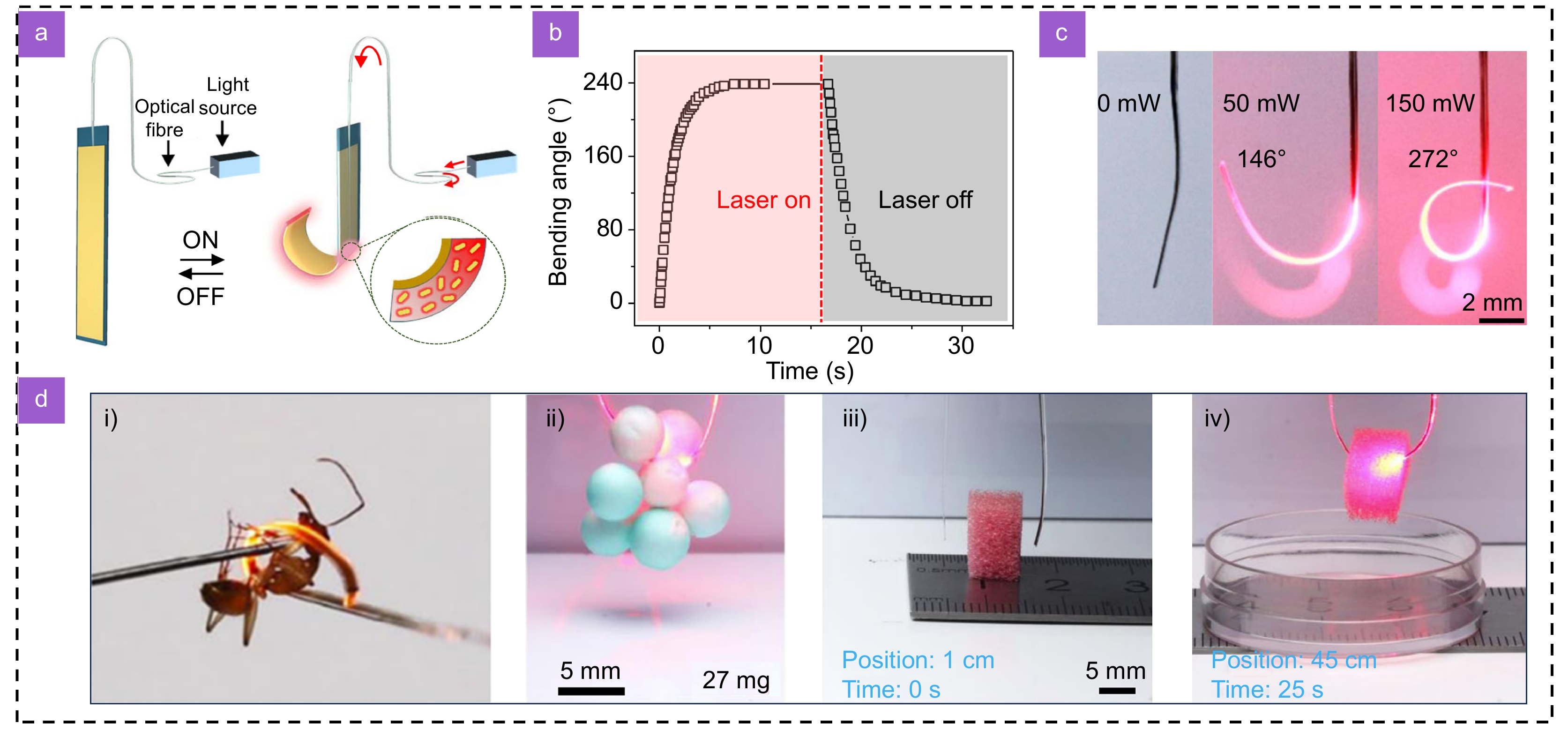

Figure 7.

MNF enabled photoactuators. (a) Schematic of the structure and driving mechanism of the photoactuator. (b) Response time of the photoactuator. (c) Photographs showing the light-driven bending of a photoactuator under different laser powers. (d) One-arm and two-arm OPA gripper capture and move ant (i), glued balls (ii), cuboid (iii, and iv). Figures reproduced with permission from ref.36, under a Creative Commons Attribution 4.0 International License.

E-mail Alert

E-mail Alert RSS

RSS

DownLoad:

DownLoad: