| Citation: | Wu J J, Zhao J B, Qiao H C, Liu X J, Zhang Y N et al. Acoustic wave detection of laser shock peening. Opto-Electron Adv 1, 180016 (2018). doi: 10.29026/oea.2018.180016 |

-

Abstract

In order to overcome the existing disadvantages of offline laser shock peening detection methods, an online detection method based on acoustic wave signals energy is provided. During the laser shock peening, an acoustic emission sensor at a defined position is used to collect the acoustic wave signals that propagate in the air. The acoustic wave signal is sampled, stored, digitally filtered and analyzed by the online laser shock peening detection system. Then the system gets the acoustic wave signal energy to measure the quality of the laser shock peening by establishing the correspondence between the acoustic wave signal energy and the laser pulse energy. The surface residual stresses of the samples are measured by X-ray stress analysis instrument to verify the reliability. The results show that both the surface residual stress and acoustic wave signal energy are increased with the laser pulse energy, and their growth trends are consistent. Finally, the empirical formula between the surface residual stress and the acoustic wave signal energy is established by the cubic equation fitting, which will provide a theoretical basis for the real-time online detection of laser shock peening. -

-

References

[1] Takata T, Enoki M, Chivavibul P, Matsui A, Kobayashi Y. Acoustic emission monitoring of laser shock peening by detection of underwater acoustic wave. Mater Trans 57, 674-680 (2016). doi: 10.2320/matertrans.M2015401 [2] Guo W, Sun R J, Song B W, Zhu Y, Li F et al. Laser shock peening of laser additive manufactured Ti6Al4V titanium alloy. Surf Coat Technol 349, 503-510 (2018). doi: 10.1016/j.surfcoat.2018.06.020 [3] Wu J J, Zhao J B, Qiao H C, Lu Y, Sun B Y et al. The application status and development of laser shock processing. Opto-Electron Eng 45, 170690 (2018). [4] Rubio-González C, Ocaña J L, Gomez-Rosas G, Molpeceres C, Paredes M et al. Effect of laser shock processing on fatigue crack growth and fracture toughness of 6061-T6 aluminum alloy. Mater Sci Eng A 386, 291-295 (2004). doi: 10.1016/j.msea.2004.07.025 [5] Peyre P, Fabbro R, Merrien P, Lieurade H P. Laser shock processing of aluminium alloys. Application to high cycle fatigue behaviour. Mater Sci Eng A 210, 102-113 (1996). doi: 10.1016/0921-5093(95)10084-9 [6] Clauer A H, Lahrman D F. Laser shock processing as a surface enhancement process. Key Eng Mater 197, 121-144 (2001). doi: 10.4028/www.scientific.net/KEM.197 [7] Montross C S, Wei T, Ye L, Clark G, Mai Y W. Laser shock processing and its effects on microstructure and properties of metal alloys: a review. Int J Fatigue 24, 1021-1036 (2002). doi: 10.1016/S0142-1123(02)00022-1 [8] Li W L, Yu L, Wang X G. Test of residual stress by hole drilling strain method. WISCO Technol 51, 55-59 (2013). [9] Gelfi M, Bontempi E, Roberti R, Depero L E. X-ray diffraction Debye Ring Analysis for STress measurement (DRAST): a new method to evaluate residual stresses. Acta Mater 52, 583-589 (2004). doi: 10.1016/j.actamat.2003.09.041 [10] Fairand B P, Wilcox B A, Gallagher W J, Williams D N. Laser shock-induced microstructural and mechanical property changes in 7075 aluminum. J Appl Phys 43, 3893-3895 (1972). doi: 10.1063/1.1661837 [11] Golden P J, Hutson A, Sundaram V, Arps J H. Effect of surface treatments on fretting fatigue of Ti-6Al-4V. Int J Fatigue 29, 1302-1310 (2007). doi: 10.1016/j.ijfatigue.2006.10.005 [12] Zhang Y K, Lu J Z, Ren X D, Yao H B, Yao H X. Effect of laser shock processing on the mechanical properties and fatigue lives of the turbojet engine blades manufactured by LY2 aluminum alloy. Mater Des 30, 1697-1703 (2009). doi: 10.1016/j.matdes.2008.07.017 [13] Varghese I, Zhou D, Peri M D M, Cetinkaya C. Thermal loading of laser induced plasma shockwaves on thin films in nanoparticle removal. J Appl Phys 101, 113106 (2007). doi: 10.1063/1.2738376 [14] Qiao H C, Zhao J B. Design and implementation of online laser peening detection system. Laser Optoelectron Prog 50, 071401 (2013). doi: 10.3788/LOP [15] Li Y H. Theory and Technology of Laser Shock Processing (Science Press, Beijing, 2013). [16] Wu X H. Review of alloy and process development of TiAl alloys. Intermetallics 14, 1114-1122 (2006). doi: 10.1016/j.intermet.2005.10.019 [17] Chan K S, Kim Y W. Influence of microstructure on crack-tip micromechanics and fracture behaviors of a two-phase TiAl alloy. Metall Trans A 23, 1663-1677 (1992). doi: 10.1007/BF02804362 [18] Yarborough J M, Lai Y Y, Kaneda Y, Hader J, Moloney J V et al. Record pulsed power demonstration of a 2 μm GaSb-based optically pumped semiconductor laser grown lattice-mismatched on an AlAs/GaAs Bragg mirror and substrate. Appl Phys Lett 95, 081112 (2009). doi: 10.1063/1.3212891 [19] Shu S L, Hou G Y, Feng J, Wang L J, Tian S C et al. Progress of optically pumped GaSb based semiconductor disk laser. Opto-Electron Adv 1, 170003 (2018). doi: 10.29026/oea.2018.170003 [20] Zhang B B, Zhao D Y, Zhao T. Adaptive sliding mode control based on disturbance observer for manipulator systems. Inf Control 47, 184-190 (2018). [21] Inasaki I. Application of acoustic emission sensor for monitoring machining processes. Ultrasonics 36, 273-281 (1998). doi: 10.1016/S0041-624X(97)00052-8 [22] Mekchar C, Wongsuwan W, Srichavengsup W, San-Um W. The implementation of cost-effective data acquisition system for acoustic emission sensor using variable gain preamplifier and STM32F4 microcontroller interface. TNI J Eng Technol 2, 18-22 (2014). [23] Pickens K S, Rzchowski M S, Bolef D I. Use of a distributed processing data-acquisition system to control an acoustic spectrometer. Rev Sci Instrum 54, 710-715 (1983). doi: 10.1063/1.1137459 [24] Ding K, Ye L. Chapter 4: Two-Dimensional Simulation of Single and Multiple Laser Shock Peening. Laser Shock Peening: Performance and Process Simulation 73-99 (Elsevier, 2006); https://doi.org/10.1533/9781845691097.73. [25] Taylor G. The formation of a blast wave by a very intense explosion I. Theoretical discussion. Proc Roy Soc A 201, 175-186 (1950). doi: 10.1098/rspa.1950.0050 [26] Wadley H N G, Dharmasena K P, He M Y, McMeeking R M, Evans A G et al. An active concept for limiting injuries caused by air blasts. Int J Impact Eng 37, 317-323 (2010). doi: 10.1016/j.ijimpeng.2009.06.006 [27] Li B Y, Zhou X C, Zhang Y S. The relationship between the energy levels of shock waves and the degree of renal damage after ESWL: A prospective clinical matching trail. J Huazhong Univ Sci Technol (Med Sci) 14, 114-118 (1994). doi: 10.1007/BF02886787 -

Access History

Article Metrics

-

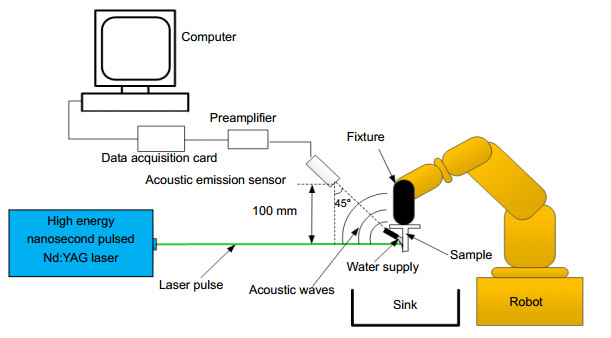

Figure 1.

Schematic diagram of experimental device.

-

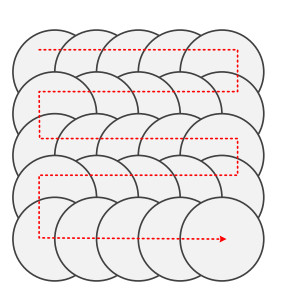

Figure 2.

Track paths' schematic of LSP.

-

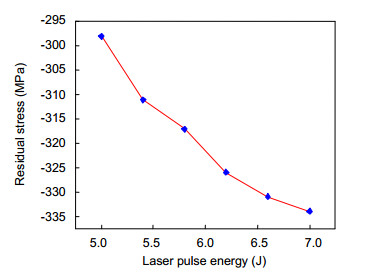

Figure 3.

Effect of laser pulse energy on surface residual stress.

-

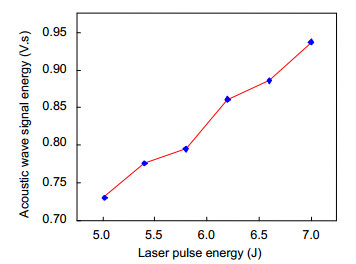

Figure 4.

Effect of laser pulse energy on acoustic wave signal energy.

-

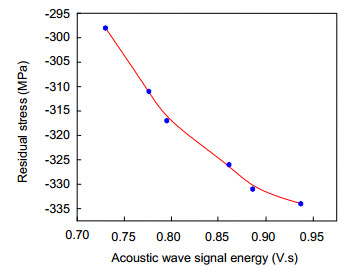

Figure 5.

The relationship between the surface residual stress and acoustic wave signal energy.

E-mail Alert

E-mail Alert RSS

RSS

DownLoad:

DownLoad: