| Citation: | Chen G, Wang AQ, Zhang Y et al. Operando monitoring of state of health for lithium battery via fiber optic ultrasound imaging system. Opto-Electron Sci x, 240036 (2025). doi: 10.29026/oes.2025.240036 |

Operando monitoring of state of health for lithium battery via fiber optic ultrasound imaging system

-

Abstract

With the rapid development of lithium batteries, it’s of great significance to ensure the safe use of it. An ultrasound imaging system based on fiber optic ultrasound sensor has been developed to monitor the internal changes of lithium batteries. Based on Fabry-Perot interferometer (FPI) structure which is made of a glass plate and an optical fiber pigtail, the ultrasound imaging system possesses a high sensitivity of 558 mV/kPa at 500 kHz with the noise equivalent pressure (NEP) of only 63.5 mPa. For the frequency response, the ultrasound sensitivity is higher than 13.1 mV/kPa within the frequency range from 50 kHz to 1 MHz. Meanwhile, the battery imaging system based on the proposed sensor has a superior resolution as high as 0.5 mm. The performance of battery safety monitoring is verified, in which three commercial lithium-ion ferrous phosphate/graphite (LFP||Gr) batteries are imaged and the state of health (SOH) for different batteries is obtained. Besides, the wetting process of an anode-free lithium metal batteries (AFLMB) is clearly observed via the proposed system, in which the formation process of the pouch cell is analyzed and the gas-related "unwetting" condition is discovered, representing a significant advancement in battery health monitoring field. In the future, the commercial usage can be realized when sensor array and artificial intelligence technology are adopted. -

-

References

[1] Marom R, Amalraj SF, Leifer N et al. A review of advanced and practical lithium battery materials. J Mater Chem 21, 9938–9954 (2011). doi: 10.1039/c0jm04225k [2] Xiang JW, Yang LY, Yuan LX et al. Alkali-metal anodes: from lab to market. Joule 3, 2334–2363 (2019). doi: 10.1016/j.joule.2019.07.027 [3] Liu B, Zhang JG, Xu W. Advancing lithium metal batteries. Joule 2, 833–845 (2018). doi: 10.1016/j.joule.2018.03.008 [4] Li YP, Zhang Y, Li Z et al. Operando decoding of surface strain in anode-free lithium metal batteries via optical fiber sensor. Adv Sci 9, 2203247 (2022). doi: 10.1002/advs.202203247 [5] Tarascon JM, Armand M. Issues and challenges facing rechargeable lithium batteries. Nature 414, 359–367 (2001). doi: 10.1038/35104644 [6] Lin XK, Khosravinia K, Hu XS et al. Lithium plating mechanism, detection, and mitigation in lithium-ion batteries. Prog Energy Combust Sci 87, 100953 (2021). doi: 10.1016/j.pecs.2021.100953 [7] Sun ZF, Li M, Xiao BS et al. In situ transmission electron microscopy for understanding materials and interfaces challenges in all-solid-state lithium batteries. eTransportation 14, 100203 (2022). doi: 10.1016/j.etran.2022.100203 [8] Itou M, Orikasa Y, Gogyo Y et al. Compton scattering imaging of a working battery using synchrotron high-energy X-rays. J Synchrotron Radiat 22, 161–164 (2015). doi: 10.1107/S1600577514024321 [9] Chen HS, Yang SQ, Song WL et al. Quantificational 4D visualization and mechanism analysis of inhomogeneous electrolyte wetting. eTransportation 16, 100232 (2023). doi: 10.1016/j.etran.2023.100232 [10] Zinth V, von Lüders C, Hofmann M et al. Lithium plating in lithium-ion batteries at sub-ambient temperatures investigated by in situ neutron diffraction. J Power Sources 271, 152–159 (2014). doi: 10.1016/j.jpowsour.2014.07.168 [11] Ziesche RF, Kardjilov N, Kockelmann W et al. Neutron imaging of lithium batteries. Joule 6, 35–52 (2022). doi: 10.1016/j.joule.2021.12.007 [12] Schindler S, Bauer M, Petzl M et al. Voltage relaxation and impedance spectroscopy as in-operando methods for the detection of lithium plating on graphitic anodes in commercial lithium-ion cells. J Power Sources 304, 170–180 (2016). doi: 10.1016/j.jpowsour.2015.11.044 [13] Harlow JE, Glazier SL, Li J et al. Use of asymmetric average charge-and average discharge-voltages as an indicator of the onset of unwanted lithium deposition in lithium-ion cells. J Electrochem Soc 165, A3595–A3601 (2018). doi: 10.1149/2.0011816jes [14] Robinson JB, Darr JA, Eastwood DS et al. Non-uniform temperature distribution in Li-ion batteries during discharge–a combined thermal imaging, X-ray micro-tomography and electrochemical impedance approach. J Power Sources 252, 51–57 (2014). doi: 10.1016/j.jpowsour.2013.11.059 [15] Jiang BQ, Zhao JL. Nanomaterial-functionalized tilted fiber gratings for optical modulation and sensing. J Lightwave Technol 41, 4103–4113 (2023). doi: 10.1109/JLT.2022.3216728 [16] Zheng HR, Liu Z, Li SC et al. Pd/WO3 Co-deposited tilted fiber bragg grating for fast hydrogen sensing. IEEE Trans Instrum Meas 74, 3522415 (2025). [17] Huang JQ, Albero Blanquer L, Bonefacino J et al. Operando decoding of chemical and thermal events in commercial Na(Li)-ion cells via optical sensors. Nat Energy 5, 674–683 (2020). doi: 10.1038/s41560-020-0665-y [18] Zhang Y, Li YP, Guo ZZ et al. Health monitoring by optical fiber sensing technology for rechargeable batteries. eScience 4, 100174 (2024). doi: 10.1016/j.esci.2023.100174 [19] Zhang Y, Hao SP, Pei F et al. Operando chemo-mechanical evolution in LiNi0.8Co0.1Mn0.1O2 cathodes. Natl Sci Rev 11, nwae254 (2024). doi: 10.1093/nsr/nwae254 [20] Matuck LC, Cabrita PD, Pinto JL et al. Customized optical fiber birefringent sensors to multipoint and simultaneous temperature and radial strain tracking of lithium‐ion batteries. Adv Sens Res 2, 2200046 (2023). doi: 10.1002/adsr.202200046 [21] Wang RL, Zhang HZ, Liu QY et al. Operando monitoring of ion activities in aqueous batteries with plasmonic fiber-optic sensors. Nat Commun 13, 547 (2022). [22] Biazi V, Moreira AC, Pinto JL et al. A particle filter-based virtual sensor for estimating the state of charge and internal temperature of lithium-ion batteries: implementation in a simulated study case. J Energy Storage 61, 106814 (2023). doi: 10.1016/j.est.2023.106814 [23] Zhang SX, Li H, Fan CZ et al. Adaptive decentralized AI scheme for signal recognition of distributed sensor systems. Opto-Electron Adv 7, 240119 (2024). doi: 10.29026/oea.2024.240119 [24] Davies G, Knehr KW, Van Tassell B et al. State of charge and state of health estimation using electrochemical acoustic time of flight analysis. J Electrochem Soc 164, A2746–A2755 (2017). doi: 10.1149/2.1411712jes [25] Wu Y, Wang YR, Yung WKC et al. Ultrasonic health monitoring of lithium-ion batteries. Electronics 8, 751 (2019). doi: 10.3390/electronics8070751 [26] Hsieh AG, Bhadra S, Hertzberg BJ et al. Electrochemical-acoustic time of flight: in operando correlation of physical dynamics with battery charge and health. Energy Environ Sci 8, 1569–1577 (2015). doi: 10.1039/C5EE00111K [27] Deng Z, Huang ZY, Shen Y et al. Ultrasonic scanning to observe wetting and “unwetting” in li-ion pouch cells. Joule 4, 2017–2029 (2020). doi: 10.1016/j.joule.2020.07.014 [28] Yang LY, Li YP, Fang F et al. Highly sensitive and miniature microfiber-based ultrasound sensor for photoacoustic tomography. Opto-Electron Adv 5, 200076 (2022). doi: 10.29026/oea.2022.200076 [29] Zhang L, Zhen YQ, Tong LM. Optical micro/nanofiber enabled tactile sensors and soft actuators: A review. Opto-Electron Sci 3, 240005 (2024). doi: 10.29026/oes.2024.240005 [30] Shum PP, Keiser G, Humbert G et al. Highly sensitive microfiber ultrasound sensor for photoacoustic imaging. Opto-Electron Adv 6, 230065 (2023). doi: 10.29026/oea.2023.230065 [31] Liu HH, Hu DJJ, Sun QZ et al. Specialty optical fibers for advanced sensing applications. Opto-Electron Sci 2, 220025 (2023). doi: 10.29026/oes.2023.220025 [32] Chen G, Xia JJ. Non-contact shear wave generation and detection using high frequency air-coupled focused transducer and fiber optic based sagnac interferometer for mechanical characterization. Sensors 22, 5824 (2022). [33] Wang JY, Ai F, Sun QZ et al. Diaphragm-based optical fiber sensor array for multipoint acoustic detection. Opt Express 26, 25293–25304 (2018). doi: 10.1364/OE.26.025293 [34] Yang LY, Xu DC, Chen G et al. Miniaturized fiber optic ultrasound sensor with multiplexing for photoacoustic imaging. Photoacoustics 28, 100421 (2022). doi: 10.1016/j.pacs.2022.100421 [35] Duque WS, Rodríguez Díaz CA, Leal-Junior AG et al. Fiber-optic hydrophone based on Michelson’s interferometer with active stabilization for liquid volume measurement. Sensors 22, 4404 (2022). doi: 10.3390/s22124404 [36] Li C, Lu SS, Zhong C et al. High-sensitivity low-frequency Fabry-Perot ultrasonic hydrophone with Chitosan diaphragm. IEEE Sens J 22, 6669–6676 (2022). doi: 10.1109/JSEN.2022.3155273 [37] Chen HB, Chen QQ, Wang W et al. Fiber-optic, extrinsic Fabry–Perot interferometric dual-cavity sensor interrogated by a dual-segment, low-coherence Fizeau interferometer for simultaneous measurements of pressure and temperature. Opt Express 27, 38744–38758 (2019). doi: 10.1364/OE.382761 [38] Yang LY, Dai CH, Wang AQ et al. Multi-channel parallel ultrasound detection based on a photothermal tunable fiber optic sensor array. Opt Lett 47, 3700–3703 (2022). doi: 10.1364/OL.464148 [39] Jiang JF, Zhang TH, Wang S et al. Noncontact ultrasonic detection in low-pressure carbon dioxide medium using high sensitivity fiber-optic Fabry–Perot sensor system. J Lightwave Technol 35, 5079–5085 (2017). doi: 10.1109/JLT.2017.2765693 [40] Ma J, Xuan HF, Ho HL et al. Fiber-optic Fabry–Pérot acoustic sensor with multilayer graphene diaphragm. IEEE Photonics Technol Lett 25, 932–935 (2013). doi: 10.1109/LPT.2013.2256343 [41] Feng DY, Zheng HR, Sun H et al. SnO2/polyvinyl alcohol nanofibers wrapped tilted fiber grating for high-sensitive humidity sensing and fast human breath monitoring. Sens Actuators B: Chem 388, 133807 (2023). doi: 10.1016/j.snb.2023.133807 [42] Guo YS, Jiang BQ, Liu L et al. In situ monitoring of curing reaction in solid composite propellant with fiber-optic sensors. ACS Sens 8, 2664–2672 (2023). doi: 10.1021/acssensors.3c00521 -

Supplementary Information

Supplementary information for Operando monitoring of state of health for lithium battery via fiber optic ultrasound imaging system

-

Access History

Article Metrics

-

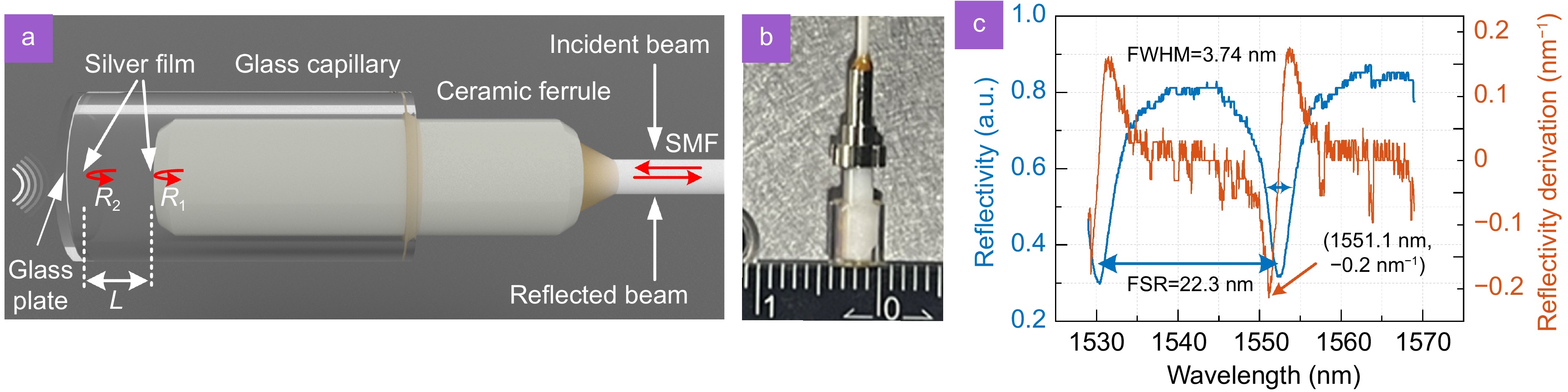

Figure 1.

(a) Schematic of the fiber optic FPI ultrasound sensor tip. (b) Photograph of the sensor tip. (c) The reflected spectrum and its derivation of the fiber optic FP ultrasound sensor.

-

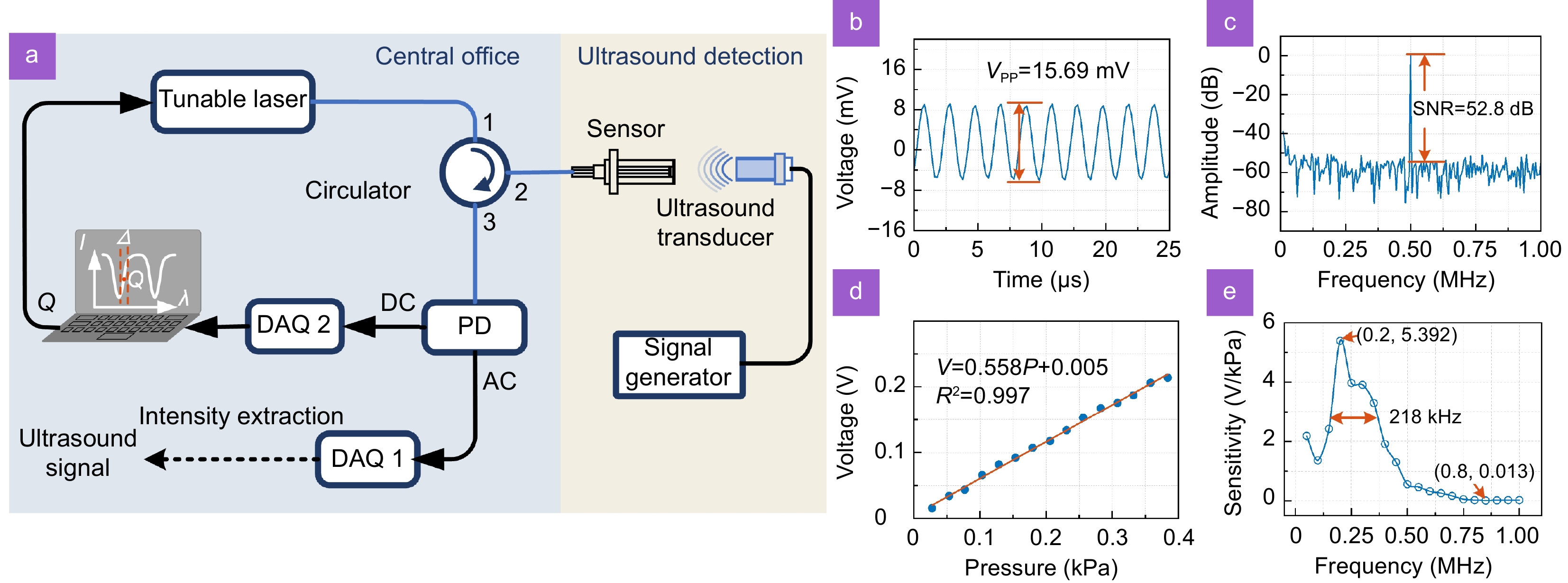

Figure 2.

(a) The schematic diagram of the ultrasound sensing demodulation system. Detected signals when the voltage frequency is 500 kHz in (b) time domain and (c) frequency domain. (d) The output voltages of the sensor when ultrasound with different pressure is applied. (e) The frequency response of the sensor.

-

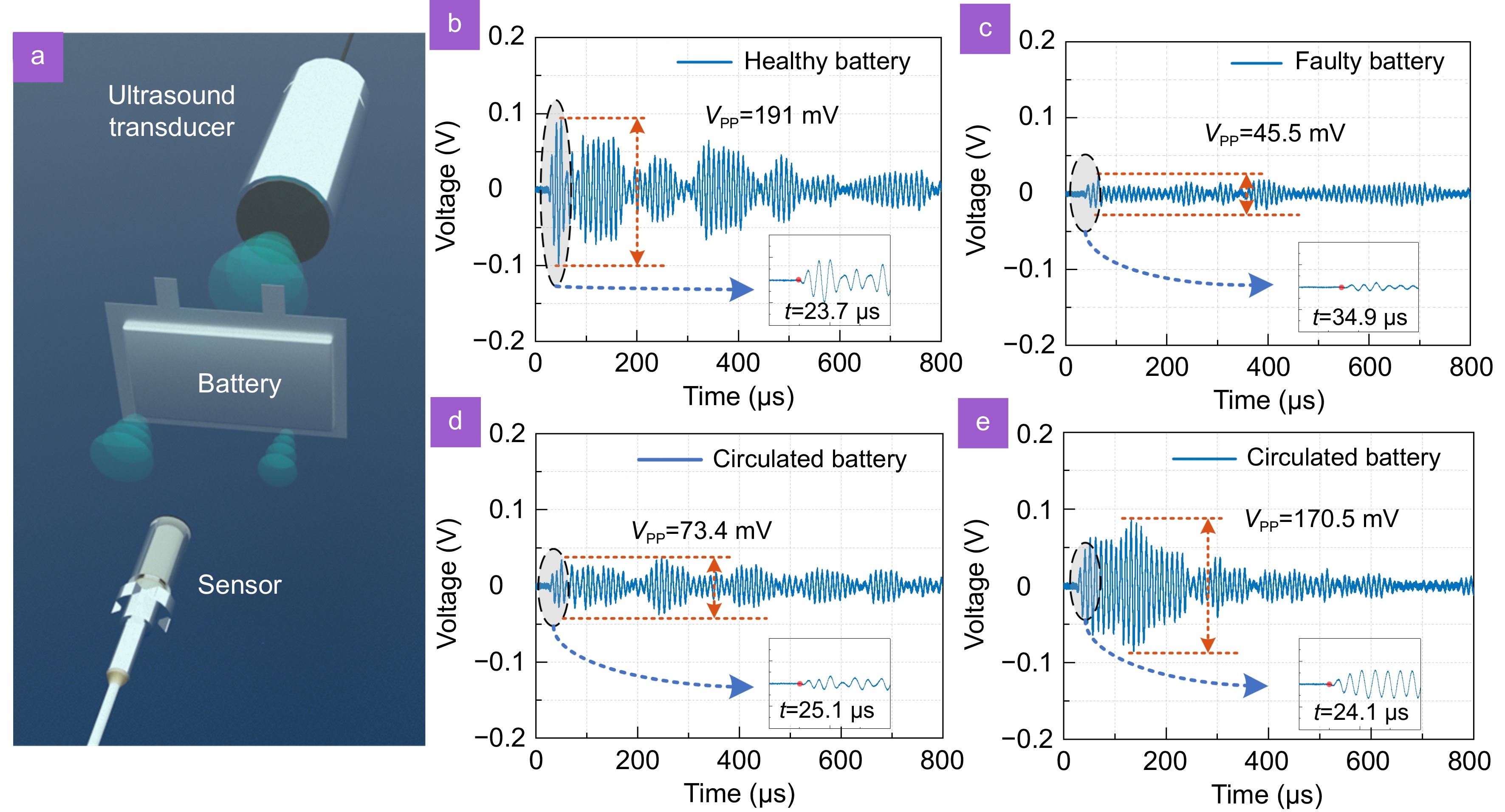

Figure 3.

(a) The simplified experiment setup of the fixed-point detection. Signals from the LFP||Gr batteries which are (b) healthy and (c) faulty. (d−e) Signals from different parts of the battery which cycles for 2000 times, respectively.

-

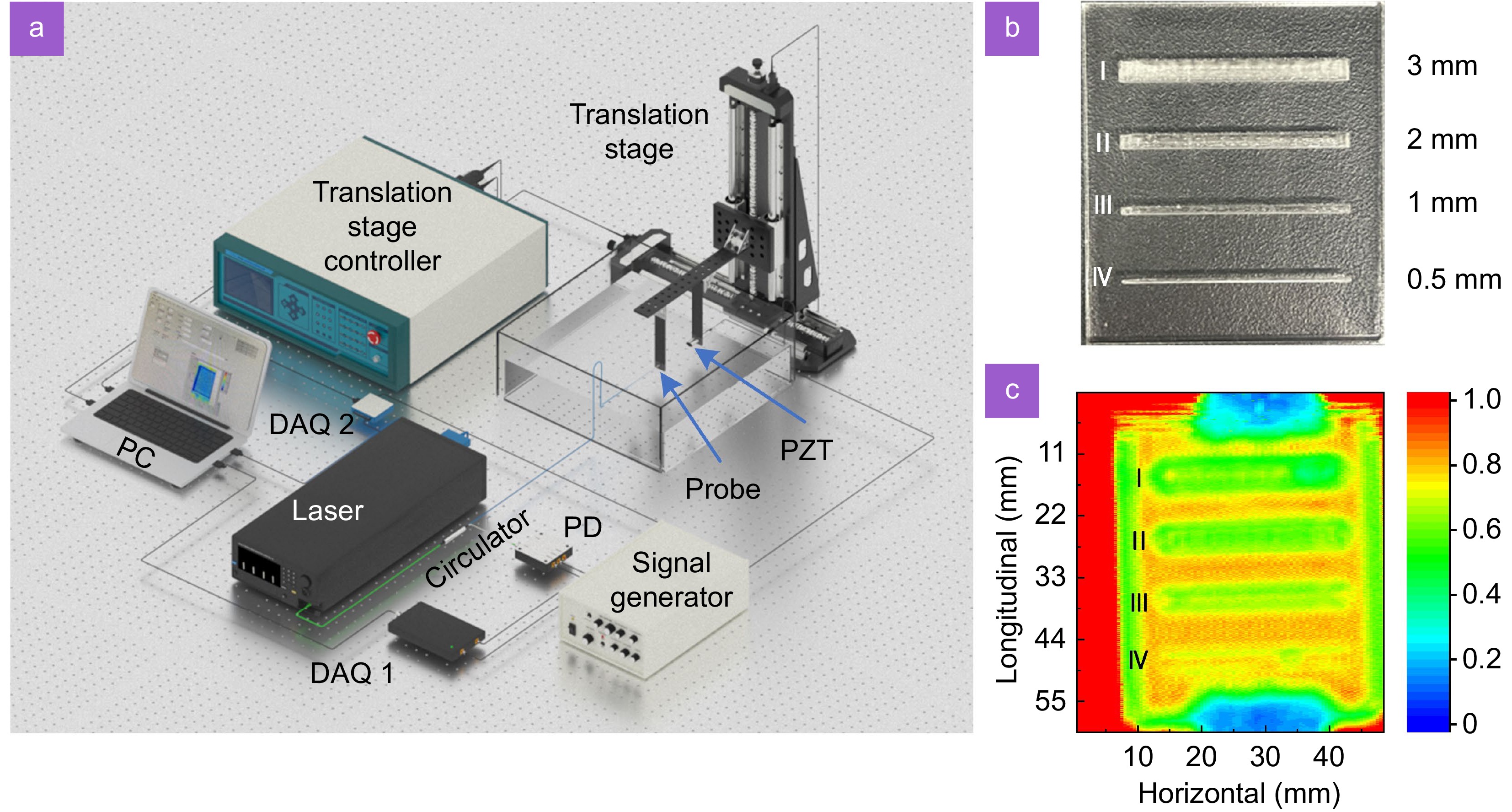

Figure 4.

(a) The schematic diagram of the fiber optic ultrasound BHM system setup. (b) The photograph of the acrylic plate. (c) The imaging result of the acrylic plate.

-

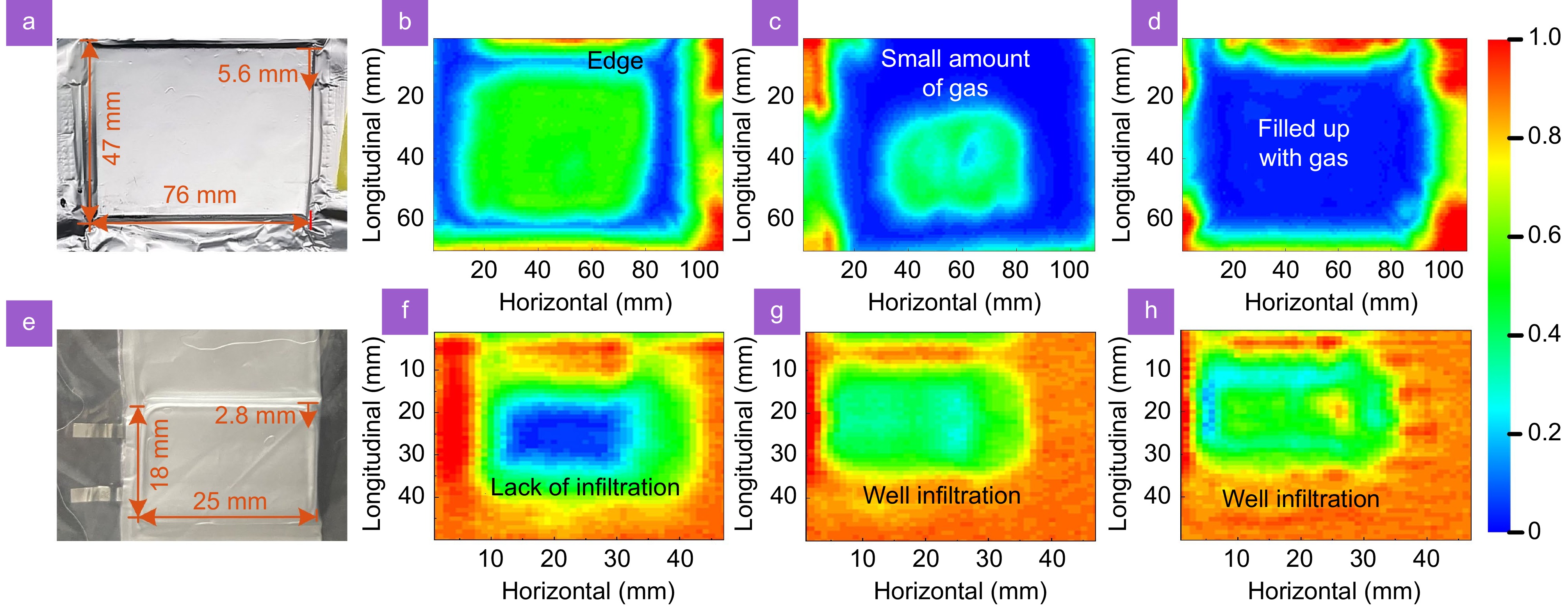

Figure 5.

(a) Photograph of the LFP||Gr battery. The ultrasound image of the (b) healthy battery, (c) battery cycled for 2000 times and (d) faulty battery. (e) The photo of the AFLMB. (f) The ultrasound image of the dry AFLMB. The ultrasound images of the AFLMB when it is injected with electrolyte after (g) 24 hours and (h) 48 hours.

-

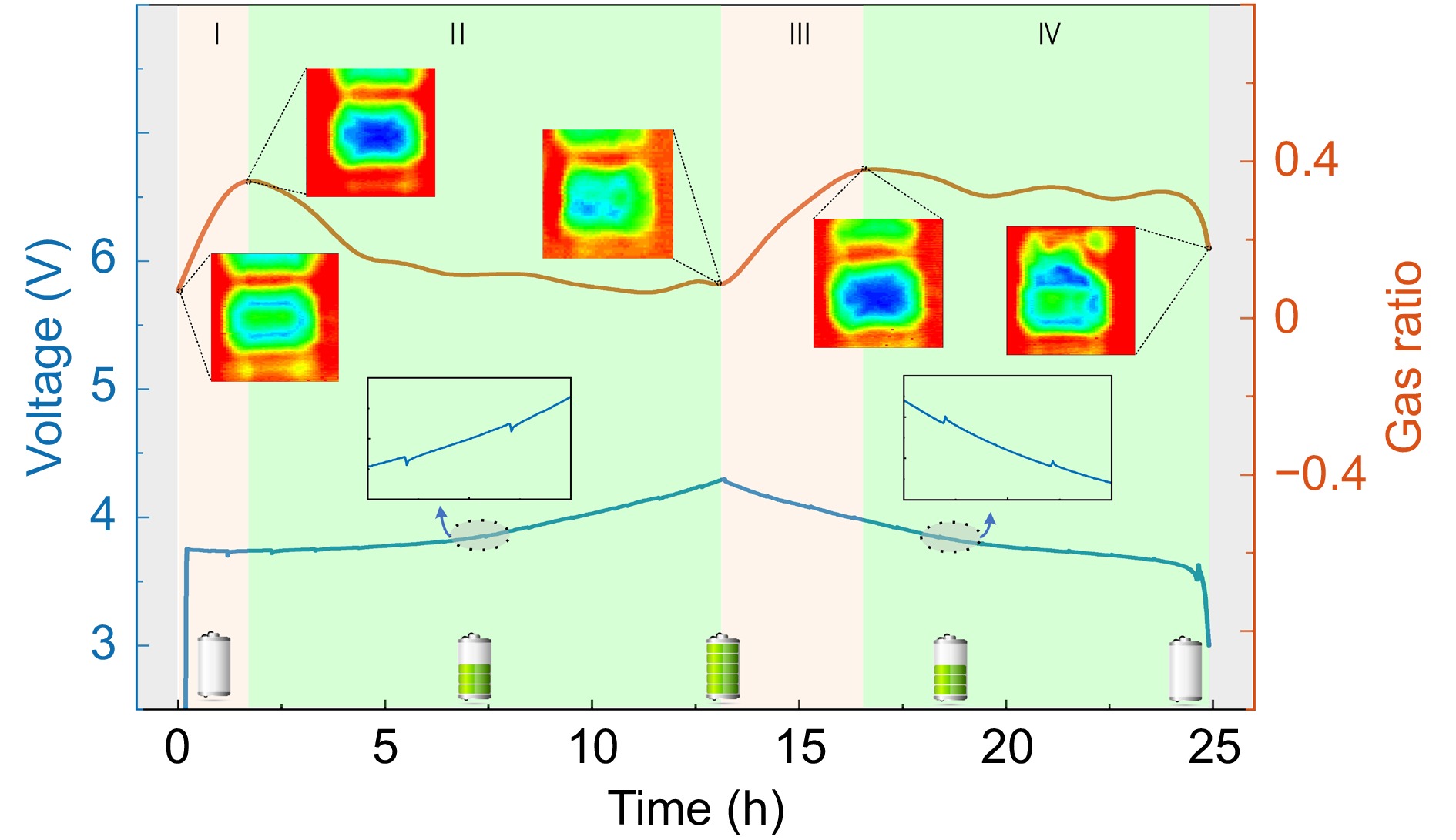

Figure 6.

The galvanostatic curves and gas ratio variation of the pouch cell in the formation process.

E-mail Alert

E-mail Alert RSS

RSS

DownLoad:

DownLoad: